T-292

4-5

secondary

controller

probes.

The

controller

continuously performs probe diagnosis testing which

compares the four probes. If the probe diagnosis result

indicates a probe problem exists, the controller will

perform a probe check to identify the probe(s) in error.

a. Probe Diagnostic Logic -- Standard

If the probe check option (controller configuration code

CnF31) is configured for standard, the criteria used for

comparison between the primary and secondary

control

probes is:

1

_

C (1.8

_

F) for perishable set points or 2

_

C (3.6

_

F)

for frozen set points.

If 25 or more of 30 readings taken within a 30 minute

period are outside of the limit, then a defrost is initi-

ated and a probe check is performed.

In this configuration, a probe check will be run as a part

of every normal (time initiated) defrost.

b. Probe Diagnostic Logic -- Special

If the probe check option is configured for special the

above criteria are applicable. A defrost with probe check

will be initiated if 25 of 30 readings or 10 consecutive

readings are outside of the limits

In this configuration, a probe check will not be run as a

part of a normal defrost, but only as a part of a defrost

initiated due to a diagnostic reading outside of the limits.

c.The 30 minute timer will be reset at each of the follow-

ing conditions:

1. At every power up.

2. At the end of every defrost.

3. After every diagnostic check that does not fall out-

side of the limits as outlined above.

d. Probe Check

A defrost cycle probe check is accomplished by

energizing just the evaporator motors for eight minutes

at the end of the normal defrost. At the end of the eight

minute period the probes will be compared to a set of

predetermined limits. The defrost indicator will remain

on throughout this period.

Any probe(s) determined to be outside the limits will

cause the appropriate alarm code(s) to be displayed to

identify which probe(s) needs to be replaced. The P5

Pre-Trip test must be run to inactivate alarms.

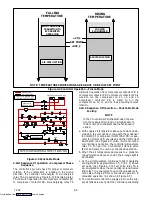

4.10 SEQUENCE OF OPERATION

General operation sequences for cooling, heating and

defrost are provided in the following subparagraphs.

Schematic representation of controller action are

provided in Figure 4-3 and Figure 4-4. Refer to Section

3 for detailed descriptions of special events and timers

that are incorporated by the controller in specific modes

of operation.

SET POINT

PULL DOWN

RISING

TEMPERATURE

--0.5

_

C

(0.9

_

F)

--0.20

_

C

+.20

_

C

HEATING

HEATING

AIR CIRCULATION

+2.5

_

C

(4.5

_

F)

UNLOADED OPERATION

MODULATED

COOLING

UNLOADED

AIR CIRCULATION

SET POINT

+.20

_

C

HEATING

+2.5

_

C

(4.5

_

F)

FALLING

TEMPERATURE

MODULATED

COOLING

UNLOADED

--0.5

_

C

(0.9

_

F)

AIR CIRCULATION

NOTE: TEMPERATURES INDICATIONS ARE ABOVE OR BELOW SET POINT

START UNLOADED,

TRANSITION TO

ECONOMIZED

OPERATION

--0.20

_

C

Figure 4-3 Controller Operation -- Perishable Mode

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...