T-292

4-6

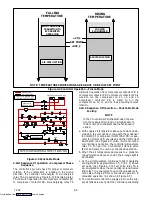

SET POINT

FALLING

TEMPERATURE

RISING

TEMPERATURE

--0.20

_

C

+.20

_

C

COOLING

ECONOMIZED

AIR CIRCULATION

START UNLOADED,

TRANSITION TO

ECONOMIZED

OPERATION

NOTE: TEMPERATURES INDICATIONS ARE ABOVE OR BELOW SET POINT

AIR CIRCULATION

Figure 4-4 Controller Operation -- Frozen Mode

CONTROL TRANSFORMER

POWER TO

CONTROLLER

SIGNAL TO

CONTROLLER

ENERGIZED

DE--ENERGIZED

FOR FULL DIAGRAM AND

LEGEND, SEE SECTION 7

NOTE: HIGH SPEED EVAPORATOR FAN SHOWN. FOR LOW SPEED

CONTACT TE IS DE--ENERGIZED AND CONTACT TV IS ENERGIZED

TD

T6

PA

PB

T6

PB

PA

USV

ESV

TU

TS

Figure 4-5 Perishable Mode

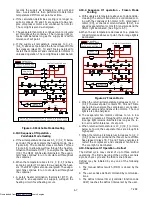

4.10.1 Sequence Of operation -- Compressor Phase

Sequence

The controller logic will check for proper compressor

rotation. If the compressor is rotating in the wrong

direction, the controller will energize or de--energize

relay T6 as required (see Figure 4-5). Energizing relay

T6 will switch operation from compressor contactor PA

to compressor contactor PB. De--energizing relay T6

will switch operation from compressor contactor PB to

compressor contactor PA. Compressor contactors PA is

wired to run the compressor on L1, L2, and L3.

Compressor contactor PB is wired to run the

compressor on L2, L1 and L3 thus providing reverse

rotation .

4.10.2 Sequence Of Operation -- Perishable Mode

Cooling

NOTE

In the Conventional Perishable Mode of opera-

tion the evaporator motors run in high speed. In

the Economy Perishable Mode the fan speed is

varied.

a. With supply air temperature above set point and de-

creasing, the unit will be cooling with the condenser

fan motor (CF), compressor motor (PA or PB), evapo-

rator fan motors (EF) energized and the COOL light

illuminated. (See Figure 4-5.) Also, if current or pres-

sure limiting is not active, the controller will energize

relay TS to open the economizer solenoid valve

(ESV) and place the unit in economized operation.

b. When the air temperature decreases to a predeter-

mined tolerance above set point, the in-range light is

illuminated.

c. As the air temperature continues to fall, modulating

cooling starts at approximately 2.5

_

C (4.5

_

F) above

set point. (See Figure 4-3.) At set point, relay TS is

de--energized to close the economizer solenoid valve

and relay TU is energized to open the unloader sole-

noid valve changing from economized operation to

unloaded operation. (As shown in Figure 4-5)

d. The controller monitors the supply air. Once the sup-

ply air falls below set point the controller periodically

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...