T-292

4-7

records the supply air temperature, set point and

time. A calculation is then performed to determine

temperature drift from set point over time.

e. If the calculation determines cooling is no longer re-

quired, contacts TD and TN are opened to de-ener-

gize compressor motor and condenser fan motor.

The cool light is also de-energized.

f. The evaporator fan motors continue to run to circulate

air throughout the container. The in-range light re-

mains illuminated as long as the supply air is within

tolerance of set point.

g. If the supply air temperature increases to 0.2

_

C

(0.4

_

F) above set point and the three minute off time

has elapsed, relays TD, TU and TN are energized to

restart the compressor and condenser fan motors in

unloaded operation. The cool light is also illuminated.

CONTROL TRANSFORMER

POWER TO

CONTROLLER

SIGNAL TO

CONTROLLER

ENERGIZED

DE--ENERGIZED

FOR FULL DIAGRAM AND

LEGEND, SEE SECTION 7

NOTE: HIGH SPEED EVAPORATOR FAN SHOWN. FOR LOW SPEED

CONTACT TE IS DE--ENERGIZED AND CONTACT TV IS ENERGIZED

TD

T6

PA

PB

T6

PB

PA

USV

ESV

TU

TS

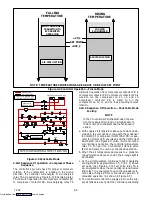

Figure 4-6 Perishable Mode Heating

4.10.3 Sequence Of Operation --

Perishable Mode Heating

a. If the air temperature decreases 0.5

_

C (0.9

_

F) below

set point, the system enters the heating mode. (See

Figure 4-3). The controller closes contacts TH (see

Figure 4-6) to allow power flow through the heat ter-

mination thermostat (HTT) to energize the heaters

(HR). The HEAT light is also illuminated. The evapo-

rator fans continue to run to circulate air throughout

the container.

b. When the temperature rises to 0.2

_

C (0.4

_

F) above

set point, contact TH opens to de--energize the heat-

ers. The HEAT light is also de--energized. The evapo-

rator fans continue to run to circulate air throughout

the container.

c. A safety heater termination thermostat (HTT), at-

tached to an evaporator coil support, will open the

heating circuit if overheating occurs.

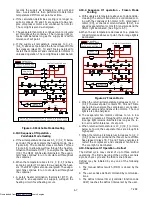

4.10.4 Sequence Of operation -- Frozen Mode

Cooling

a. With supply air temperature above set point and de-

creasing, the unit will transition to economized cool-

ing with the condenser fan motor (CF), compressor

motor (CH), economizer solenoid valve (ESV), low

speed evaporator fan motors (ES) energized and the

COOL light illuminated. (See Figure 4-7.)

b.When the air temperature decreases to a predeter-

mined tolerance above set point, the in-range light is

illuminated.

CONTROL TRANSFORMER

POWER TO

CONTROLLER

SIGNAL TO

CONTROLLER

ENERGIZED

DE--ENERGIZED

FOR FULL DIAGRAM AND

LEGEND, SEE SECTION 7

TD

T6

PA

PB

T6

PB

PA

USV

ESV

TU

TS

Figure 4-7 Frozen Mode

c. When the return air temperature decreases to 0.2

_

C

(0.4

_

F) below set point, contacts TD, TS and TN are

opened to de-energize the compressor, economizer

solenoid valve and condenser fan motors. The cool

light is also de-energized.

d. The evaporator fan motors continue to run in low

speed to circulate air throughout the container. The

in-range light remains illuminated as long as the re-

turn air is within tolerance of set point.

e. When return air temperature is 10

_

C (18

_

F) or more

below set point, the evaporator fans are brought to

high speed.

f. When the return air temperature increases to 0.2

_

C

(0.4

_

F) above set point and the three minute off time

has elapsed, relays TD, TS and TN are energizes to

restart the compressor and condenser fan motors.

The cool light is illuminated.

4.10.5 Sequence Of Operation -- Defrost

The defrost cycle may consist of up to three distinct

operations. The first is de-icing of the coil, the second is

a probe check cycle and the third is snap freeze.

Defrost may be initiated by any one of the following

methods:

1. The manual defrost switch (MDS) is closed by the

user.

2. The user sends a defrost command by communica-

tions.

3. The defrost interval timer (controller function code

Cd27) reaches the defrost interval set by the user.

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

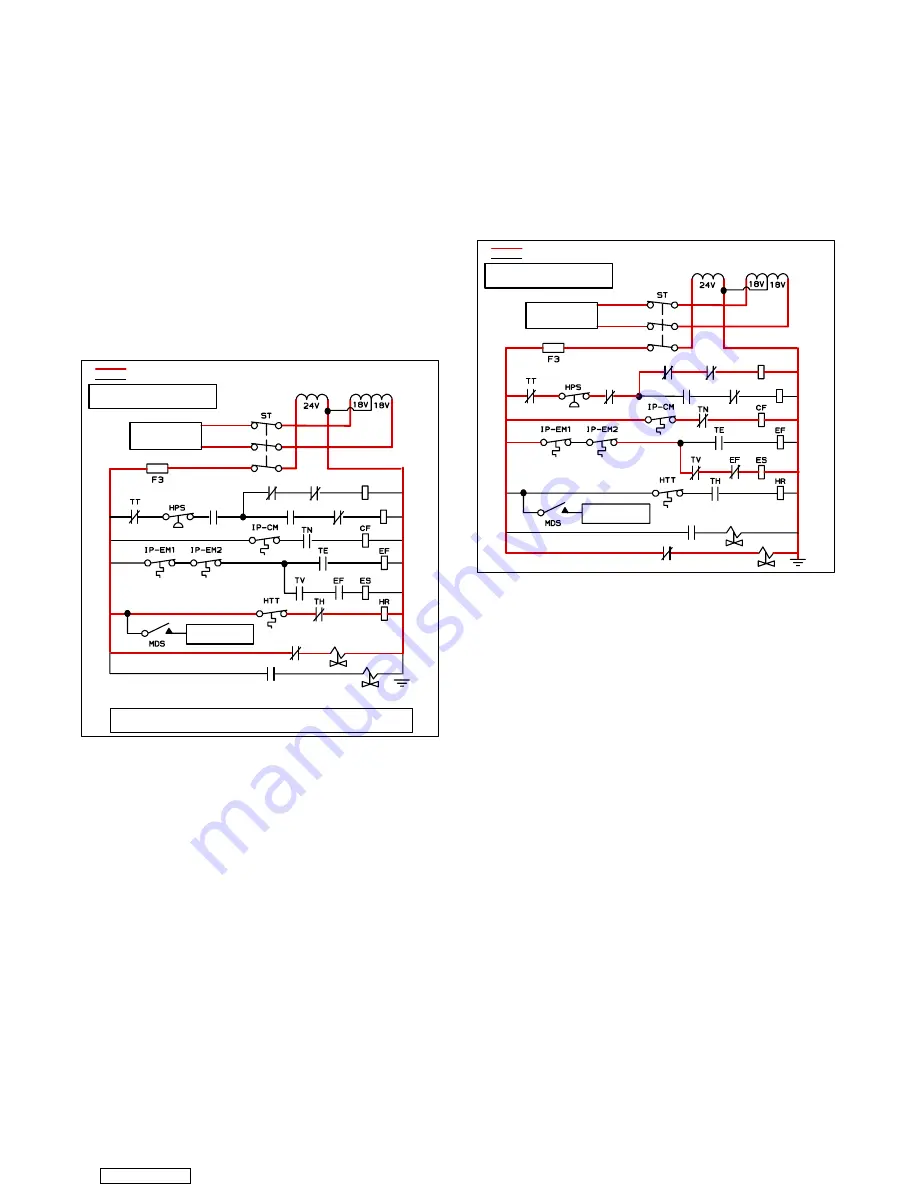

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...