6-1

T-292

SECTION 6

SERVICE

NOTE

To avoid damage to the earth’s ozone layer, use a refrigerant recovery system whenever removing refriger-

ant. When working with refrigerants you must comply with all local government environmental laws. In the

U.S.A., refer to EPA section 608.

WARNING

Never use air for leak testing. It has been de-

termined that pressurized, mixtures of re-

frigerant and air can undergo combustion

when exposed to an ignition source.

6.1 SECTION LAYOUT

Service procedures are provided herein beginning with

refrigeration system service, then refrigeration system

component

service,

electrical

system

service,

temperature recorder service and general service. The

refrigeration section divided in to standard unit (with

service valves) and semi--hermetic systems (equipped

with service fittings). Refer to the Table Of Contents to

locate specific topics.

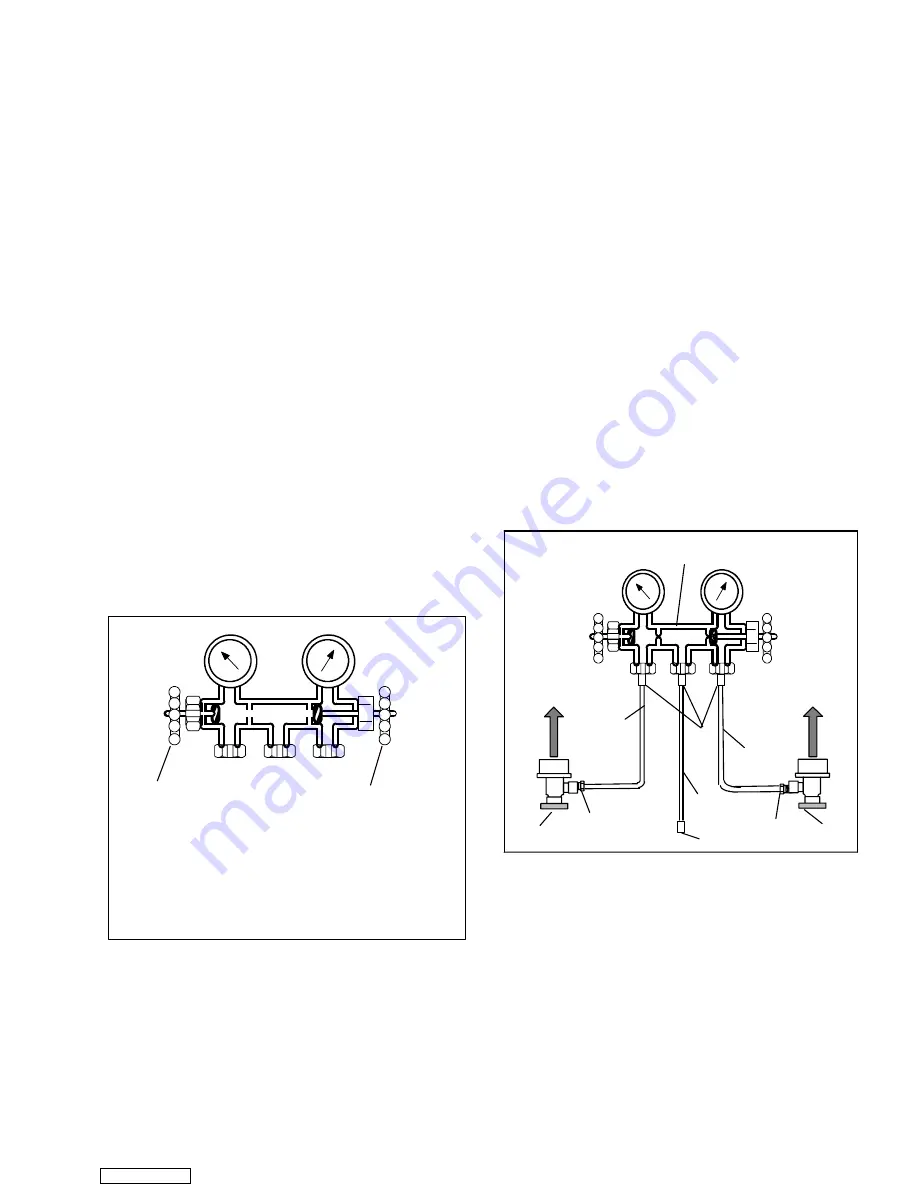

6.2 MANIFOLD GAUGE SET

The manifold gauge set (see Figure 6-1) is used to

determine system operating pressure, add refrigerant

charge, and to equalize or evacuate the system.

OPENED (Backseated )

HAND VALVE

CLOSED (Frontseated)

HAND VALVE

SUCTION

PRESSURE

GAUGE

DISCHARGE

PRESSURE

GAUGE

A

B

C

A. CONNECTION TO LOW SIDE OF SYSTEM

B. CONNECTION TO EITHER:

REFRIGERANT CYLINDER OR

OIL CONTAINER

C. CONNECTION TO HIGH SIDE OF SYSTEM

Figure 6-1 Manifold Gauge Set

When the suction pressure hand valve is frontseated

(turned all the way in), the suction (low) pressure can be

checked. When the discharge pressure hand valve is

frontseated, the discharge (high) pressure can be

checked. When both valves are open (all the way out),

high pressure vapor will flow into the low side. When the

suction pressure valve is open and the discharge

pressure valve shut, the system can be charged. Oil can

also be added to the system.

A R-134a manifold gauge/hose set with self-sealing

hoses (see Figure 6-2) is required for service of the

models covered within this manual. The manifold

gauge/hose set is available from Carrier Transicold.

(Carrier Transicold P/N 07-00294-00, which includes

items 1 through 6, Figure 6-2.) To perform service using

the manifold gage/hose set, do the following:

a. Preparing Manifold Gauge/Hose Set For Use

1. If the manifold gauge/hose set is new or was

exposed to the atmosphere it will need to be eva-

cuated to remove contaminants and air as follows:

2. Back seat (turn counterclockwise )both field service

couplings (see Figure 6-2) and midseat both hand

valves.

3. Connect the yellow hose to a vacuum pump and re-

frigerant 134a cylinder.

OPENED

(Backseated )

HAND VALVE

CLOSED

(Frontseated)

HAND VALVE

SUCTION

PRESSURE

GAUGE

DISCHARGE

PRESSURE

GAUGE

To Low Side

Access Valve

To High Side

Access Valve

Red Knob

Blue Knob

1

4

3

YELLOW

2

4

5

6

3

RED

3

BLUE

2

1. Manifold Gauge Set

2. Hose Fitting (0.5-16 Acme)

3. Refrigeration and/or Evacuation Hose

.

(SAE J2196/R-134a)

4. Hose Fitting w/O-ring (M14 x 1.5)

5. High Side Field Service Coupling

6. Low Side Field Service Coupling

Figure 6-2 R-134a Manifold Gauge/Hose Set

7. Evacuate to 10 inches of vacuum and then charge

with R-134a to a slightly positive pressure of 0.1 kg/

cm

@

(1.0 psig).

8. Front seat both manifold gauge set valves and dis-

connect from cylinder. The gauge set is now ready

for use.

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...