6-4

T-292

c. The area between the suction modulating valve and

evaporator expansion valve may not be open to the

access valves. To ensure evacuation of this area,

check that the suction modulating valve is more than

10% open at controller function code Cd01. If re-

quired, the suction modulating valve may be opened

by use of the controller function code Cd41 valve

override control. If power is not available to open the

valve, the area may be evacuated by connecting an

additional hose at the low side access valve (item 15,

Figure 2-2).

d. Test the evacuation setup for leaks by backseating

the unit service valves and drawing a deep vacuum

with the vacuum pump and gauge valves open. Shut

off the pump and check to see if the vacuum holds.

Repair leaks if necessary.

e. Midseat the refrigerant system service valves.

f. Open the vacuum pump and electronic vacuum

gauge valves, if they are not already open. Start the

vacuum pump. Evacuate unit until the electronic vac-

uum gauge indicates 2000 microns. Close the elec-

tronic vacuum gauge and vacuum pump valves. Shut

off the vacuum pump. Wait a few minutes to be sure

the vacuum holds.

g. Break the vacuum with clean dry refrigerant 134a

gas. Raise system pressure to approximately 0.2 kg/

cm

@

(2 psig), monitoring it with the compound gauge.

h. Remove refrigerant using a refrigerant recovery sys-

tem.

i. Repeat steps f.and g. one time.

j. Remove the copper tubing and change the filter-drier.

Evacuate unit to 500 microns. Close the electronic

vacuum gauge and vacuum pump valves. Shut off the

vacuum pump. Wait five minutes to see if vacuum

holds. This procedure checks for residual moisture

and/or leaks.

k. With a vacuum still in the unit, the refrigerant charge

may be drawn into the system from a refrigerant con-

tainer on weight scales.

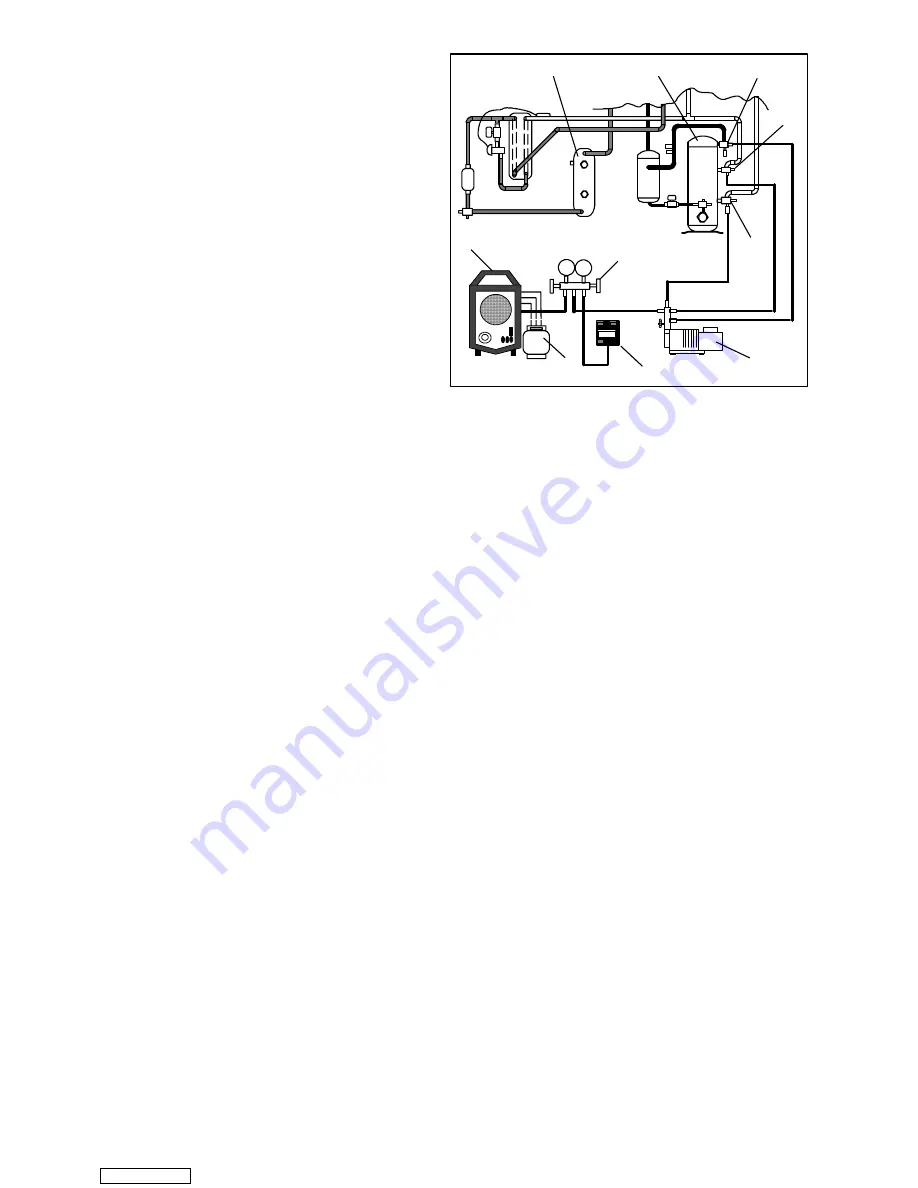

Procedure - Partial System

a. If the refrigerant charge has been removed from the

compressor for service, evacuate only the compres-

sor by connecting the evacuation set--up at the com-

pressor service valves. (See Figure 6-5.) Follow

evacuation procedures of the preceding paragraph

except leave compressor service valves frontseated

until evacuation is completed.

b. If refrigerant charge has been removed from the low

side only, evacuate the low side by connecting the

evacuation set--up at the compressor suction and

economizer service valves and the liquid service

valve except leave the service valves frontseated un-

til evacuation is completed.

c. Once evacuation has been completed and the pump

has been isolated, fully backseat the service valves to

isolate the service connections and then continue

with checking and, if required, adding refrigerant in

accordance with normal procedures

6

4

5

7

D

S

10

1

2

3

8

9

1. Receiver or Water

Cooled Condenser

2. Compressor

3. Discharge Service

Valve

4. Economizer Service

Valve

5. Suction Service Valve

6. Vacuum Pump

7. Electronic Vacuum

Gauge

8. Manifold Gauge Set

9. Refrigerant Cylinder

10. Reclaimer

Figure 6-5. Standard Piping Compressor Service

Connections

6.3.5 Refrigerant Charge

Checking the Refrigerant Charge

NOTE

To avoid damage to the earth’s ozone layer, use

a refrigerant recovery system whenever remov-

ing refrigerant. When working with refrigerants

you must comply with all local government envi-

ronmental laws. In the U.S.A., refer to EPA sec-

tion 608.

a. Connect the gauge manifold to the compressor dis-

charge and suction service valves. For units operat-

ing on a water cooled condenser, change over to air

cooled operation.

b. Bring the container temperature to approximately

1.7

_

C (35

_

F) or --17.8

_

C (0

_

F). Then set the control-

ler set point to --25

_

C (--13

_

F) to ensure that the suc-

tion modulation valve is fully open. (Position of the

suction modulating valve may be checked at control-

ler function code Cd01.)

c. Partially block the condenser coil inlet air. Increase

the area blocked until the compressor discharge

pressure is raised to approximately 12 kg/cm

@

(175

psig).

d. On units equipped with a receiver, the level should be

between the glasses. On units equipped with a water

cooled condenser, the level should be at the center of

the glass. If the refrigerant level is not correct, contin-

ue with the following paragraphs to add or remove re-

frigerant as required.

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...