6-6

T-292

c. Break the vacuum and bring the system to a slight

positive pressure using dry nitrogen. When refriger-

ant is fully recovered, remove the refrigerant recovery

unit.

d. Perform repairs as required and then leak test, evac-

uate, charge and reseal unit in accordance with the

following paragraphs.

6.4.3 Refrigerant Leak Checking

WARNING

Never use air for leak testing. It has been

determined that pressurized, air-rich mix-

tures of refrigerants and air can undergo

combustion when exposed to an ignition

source

The recommended procedure for finding leaks in a

system is with a R-134a electronic leak detector. Testing

joints with soapsuds is satisfactory only for locating

large leaks.

NOTE

Only refrigerant 134a should be used to pres-

surize the system. Any other gas or vapor will

contaminate the system, which will require

additional purging and evacuation of the sys-

tem.

If the system is without refrigerant, charge with

refrigerant 134a to build up pressure between 2.1 to 3.5

kg/cm

@

(30 to 50 psig).

To ensure complete pressurization of the system,

refrigerant should be charged at all of the access valves.

DO NOT charge liquid at the suction or economizer

fittings, charge only vapor.

Liquid may be charged at the liquid line. To ensure

pressure to this area, check that the suction modulating

valve is more than 10% open at controller function code

Cd01. The suction modulating valve may be opened by

use of the controller function code Cd41 valve override

control (refer to paragraph 6.20).

Remove refrigerant cylinder and leak-check all

connections.

If required, remove refrigerant using a refrigerant

recovery system and repair any leaks

Evacuate, dehydrate and charge the unit in accordance

with the following paragraphs

6.4.4 Evacuation and Dehydration

General

The presence of moisture in a refrigeration system can

have many undesirable effects. The most common are

copper plating, acid sludge formation, “freezing-up” of

metering devices by free water, and formation of acids,

resulting in metal corrosion.

Preparation

Evacuate and dehydrate only after pressure leak test.

Essential tools to properly evacuate and dehydrate any

system include a vacuum pump (8 m

3

/hr = 5 cfm volume

displacement) and an electronic vacuum gauge. (The

pump is available from Carrier Transicold, P/N

07-00176-11.)

Additional time may be saved during a complete system

pump down by replaceing the filter-drier with a section of

copper tubing.

Procedure

a. Remove all refrigerant using a refrigerant recovery

system. Refer to section 6.4.2.

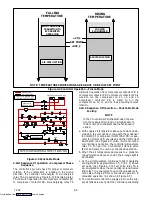

b. The recommended method to evacuate and dehy-

drate the system is to connect evacuation hoses at

the liquid, economizer and suction access val-

ves.(see Figure 6--6). Be sure the service hoses are

suited for evacuation purposes.

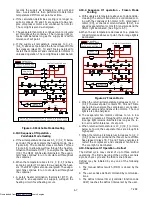

c. The area between the suction modulating valve and

evaporator expansion valve may not be open to the

access valves. To ensure evacuation of this area,

check that the suction modulating valve is more than

10% open at controller function code Cd01. If re-

quired, the suction modulating valve may be opened

by use of the controller function code Cd41 valve

override control.

d. Test the evacuation setup for leaks and drawing a

deep vacuum with the vacuum pump and gauge

valves open. Shut off the pump and check to see if the

vacuum holds. Repair leaks if necessary.

e. If possible, keep the ambient temperature above

15.6

_

C (60

_

F) to speed evaporation of moisture. If

the ambient temperature is lower than 15.6

_

C

(60

_

F), ice might form before moisture removal is

complete. Heat lamps or alternate sources of heat

may be used to raise the system temperature.

f. Open the vacuum pump and electronic vacuum

gauge valves, if they are not already open. Start the

vacuum pump. Evacuate unit until the electronic vac-

uum gauge indicates 2000 microns. Close the elec-

tronic vacuum gauge and vacuum pump valves. Shut

off the vacuum pump. Wait a few minutes to be sure

the vacuum holds.

g. Break the vacuum with clean dry refrigerant 134a

gas. Raise system pressure to approximately 0.2 kg/

cm

@

(2 psig), monitoring it with the compound gauge.

h. Remove refrigerant using a refrigerant recovery sys-

tem.

i. Repeat steps f.and g. one time.

j. Remove the copper tubing and change the filter-drier.

Evacuate unit to 500 microns. Close the electronic

vacuum gauge and vacuum pump valves. Shut off the

vacuum pump. Wait five minutes to see if vacuum

holds. This procedure checks for residual moisture

and/or leaks.

k. With a vacuum still in the unit, the refrigerant charge

may be drawn into the system from a refrigerant con-

tainer on weight scales.

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...