6-13

T-292

6.11 FILTER-DRIER

On units equipped with a water-cooled condenser, if the

sight glass appears to be flashing or bubbles are

constantly moving through the sight glass when the

suction modulation valve is fully open, the unit may have

a low refrigerant charge or the filter-drier could be

partially plugged.

a. To Check Filter-Drier

1. Test for a restricted or plugged filter-drier by feeling

the liquid line inlet and outlet connections of the drier

cartridge. If the outlet side feels cooler than the inlet

side, then the filter-drier should be changed.

2. Check the moisture-liquid indicator if the indicator

shows a high level of moisture, the filter-drier should

be replaced.

b. To Replace Filter-Drier

1. Pump down the unit (refer to paragraph 6.3.2). Eva-

cuate if unit is not equipped with service valves (Re-

fer to paragraph 6.4.4). Then replace filter-drier.

2. Evacuate the low side in accordance with paragraph

6.3.4.

3. After unit is in operation, inspect for moisture in sys-

tem and check charge.

6.12 EXPANSION VALVES

Three expansion valves are used, the evaporator

expansion valve (item 12, Figure 2-2), the quench

expansion valve (item 14, Figure 2-2) and the

economizer expansion valve (item 26, Figure 2-4). The

expansion valves are automatic devices which maintain

constant superheat of the refrigerant gas leaving at the

point of bulb attachment regardless of suction pressure.

The valve functions are:

1. Automatic control of the refrigerant flow to match the

load.

2. Prevention of liquid refrigerant entering the com-

pressor.

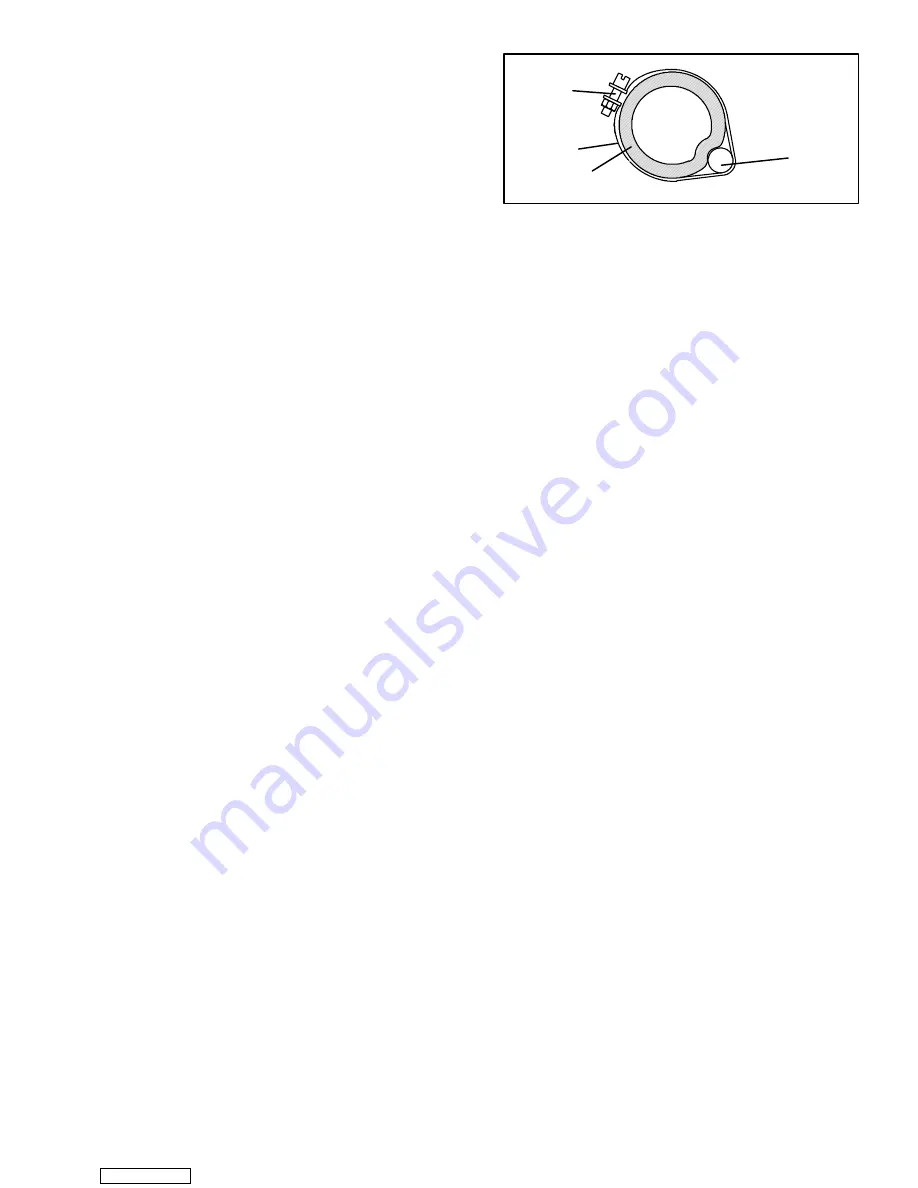

Unless the valve is defective, it seldom requires

maintenance other than periodic inspection to ensure

that the thermal bulb is tightly secured to the suction line

and wrapped with insulating compound. (See

Figure 6-12.)

1

2

3

4

1. Suction Line

2. TXV Bulb Clamp

3. Nut and Bolt

4. TXV Bulb

Figure 6-12 Thermostatic Expansion Valve Bulb

6.12.1 Checking Superheat.

NOTE

Proper superheat measurement for the evapo-

rator expansion valve should be completed at

--18

_

C (0

_

F) container box temperature where

possible. If the economizer or quench valve is

suspect, it should be replaced.

a. Open the heater access panel (see Figure 2-1) to ex-

pose the evaporator expansion valve.

b. Attach a temperature sensor near the expansion

valve bulb and insulate. Make sure the suction line is

clean and that firm contact is made with the sensor.

c. Connect an accurate gauge to the service port direct-

ly upstream of the suction modulating valve.

d. Set the temperature set point to --18

_

C (0

_

F), and run

unit until conditions stabilize.

e. The readings may cycle from a high to a low reading.

Take readings of temperature and pressure every

three to five minutes for a total of 5or 6 readings

f. From the temperature/pressure chart (Table 6-8), de-

termine the saturation temperature corresponding to

the evaporator outlet test pressures at the suction

modulation valve.

g. Subtract the saturation temperatures determined in

step f. from the temperatures measured in step e..

The difference is the superheat of the suction gas.

Determine the average superheat It should be 4.5 to

6.7

°

C (8 to 12

°

F)

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...