6-17

T-292

1

2

3

4

5

6

5

7

8

9

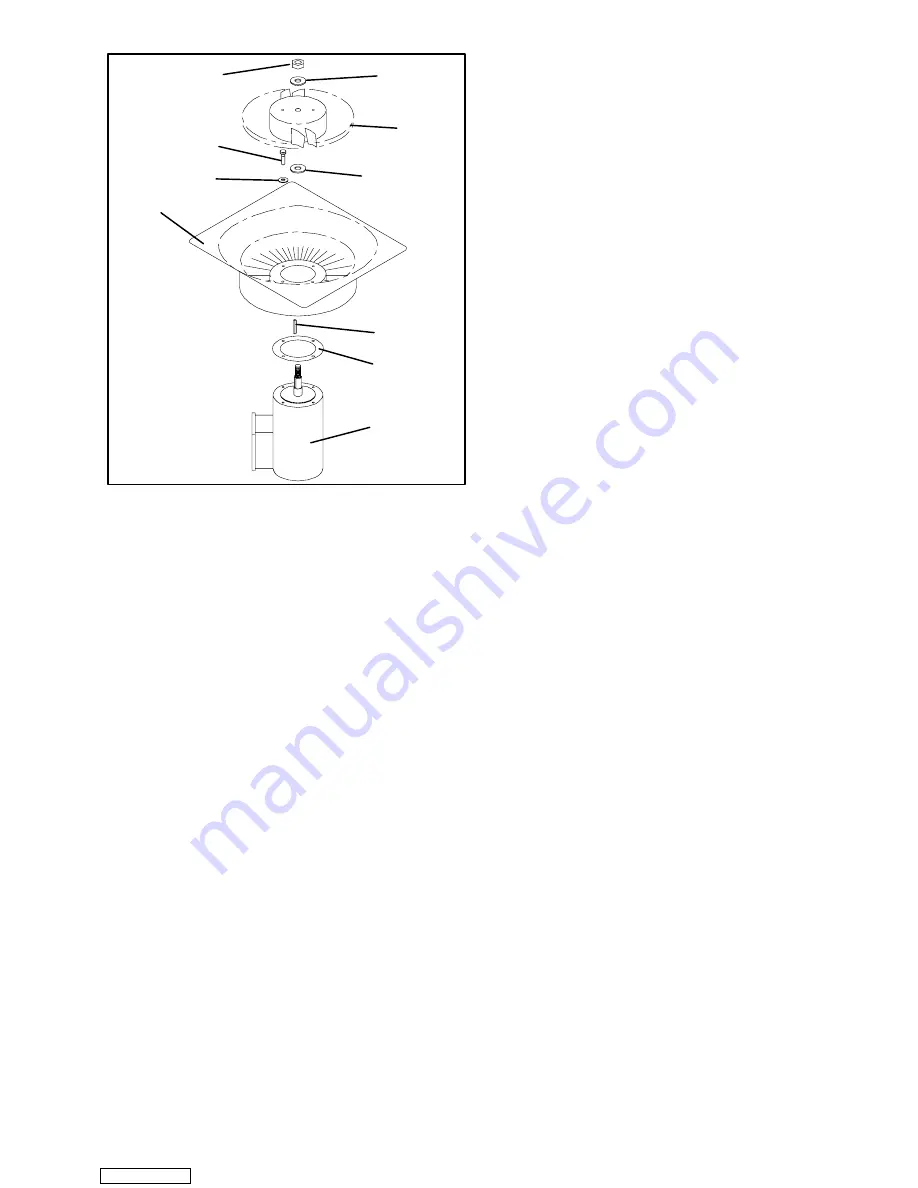

1. Stator

2. Flat washer, 1/4

3. Bolt, 1/4-20 x 3/4

4. Locknut, 5/8-18

5. Flat washer, 5/8

6. Impeller Fan

7. Key

8. Mylar Protector

9. Evaporator Motor

Figure 6-18. Evaporator Fan Assembly

6.16 EVAPORATOR FAN MOTOR CAPACITORS

The evaporator fan motors are of the permanent-split

capacitor type. The motor is equipped with one

capacitor used in the high speed circuit and another

capacitor used for the low speed circuit.

6.16.1 When To Check For A Defective Capacitor

a. Fan motor will not change speed. For example: in the

conventional perishable mode, the motors should run

in high speed. In the economy perishable mode they

should switch speeds and in the frozen mode, the mo-

tors should run in low speed.

NOTE

The evaporator fan motors will always start in

high speed.

b. Motor running in wrong direction (after checking for

correct wiring application).

c. Motor will not start, and IP-EM’s are not open.

6.16.2 Removing The Capacitor

WARNING

Make sure power to the unit is OFF and

power plug disconnected before removing

capacitor(s).

The capacitors are located on the motor and above the

evaporator fan deck they may be removed by two

methods:

1

If container is empty

, open upper rear panel of the

unit. The capacitor may be serviced after discon-

necting power plug.

2

If container is full,

turn the unit power OFF and dis-

connect power plug. Remove the evaporator fan

motor access panel. (See Figure 2-1). For removal

of the evaporator fan assembly, refer to section 6.15.

WARNING

With power OFF discharge the capacitor

before disconnecting the circuit wiring.

6.16.3 Checking The Capacitor

If the capacitor is suspected of malfunction, you may

choose to simply replace it. Direct replacement requires

a capacitor of the same value. Two methods for

checking capacitor function are:

1. Volt-ohmmeter set on RX 10,000 ohms.

Connect ohmmeter leads across the capacitor

terminals and observe the meter needle. If the capacitor

is good, the needle will make a rapid swing toward zero

resistance and then gradually swing back toward a very

high resistance reading.

If the capacitor has failed open, the ohmmeter needle

will not move when the meter probes touch the

terminals. If the capacitor is shorted, the needle will

swing to zero resistance position and stay there.

2. Capacitor analyzer:

The function of the analyzer is to read the microfarad

value of a capacitor and to detect insulation breakdown

under load conditions. The important advantages of a

analyzer are its ability to locate capacitors that have

failed to hold their microfarad ratings, or those that are

breaking down internally during operation. It is also

useful in identifying capacitors when their microfarad

rating marks have become unreadable.

6.17 VALVE OVERRIDE CONTROLS

Controller function code Cd41 is a configurable code

that allows timed operation of the automatic valves for

troubleshooting. Three test sequences are provided.

The first, capacity mode (CAP), allows alignment of the

unloader and economizer solenoid valves in the

standard, unloaded and economized operating

configurations. The second, SMV % Setting (SM)

allows opening of the suction modulating valve to

various percentages and the third, Oil Valve Setting

(OIL) allows opening or closing of the oil return solenoid

valve.

A fourth selection is also provided to enter a time period

of up to three minutes, during which the override(s) are

active. If the timer is active, valve override selections will

take place immediately. If the timer is not active,

changes will not take place for a few seconds after the

timer is started. When the timer times out, override

function is automatically terminated and the valves

return to normal machinery control. To operate the

override, do the following:

a. Press the CODE SELECT key then press an AR-

ROW key until Cd41 is displayed in the left window.

The right window will display a controller communica-

tions code.

b. Press the ENTER key. The left display will show a test

name alternating with the test setting or time remain-

ing. Use an ARROW key to scroll to the desired test.

Press the ENTER key and SELCt will appear in the

left display.

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...