6-20

T-292

TP3

This test point enables the user to check if the water

pressure switch (WP) contact is open or closed.

TP 4

This test point enables the user to check if the internal

protector for the condenser fan motor(IP-CM) is open or

closed.

TP 5

This test point enables the user to check if the internal

protectors for the evaporator fan motors (IP-EM1 or

IP-EM2) are open or closed.

TP 6

This test point is not used in this application.

TP 7

This test point enables the user to check if the controller

economizer solenoid valve relay (TS) is open or closed

TP 8

This test point enables the user to check power to the

suction modulator valve.

TP 9

This test point is the chassis (unit frame) ground

connection.

TP 10

This test point enables the user to check if the heat

termination thermostat (HTT) contact is open or closed.

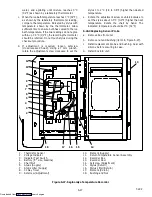

6.20.3 Controller Programming Procedure

To load new software into the module, the programming

card is inserted into the programming/software port.

CAUTION

The unit must be OFF whenever a program-

ming card is inserted or removed from the

controller programming port.

NOTE

The metal door on the programming card must

be facing to the left when inserting.

a. Procedure for loading Operational Software

1. Turn unit OFF, via start-stop switch (ST).

2. Insert the programming card for Operational Soft-

ware into the programming/software port. (See

Figure 6-20)

3. Turn unit ON, via start-stop switch (ST).

4. The Display module will alternate back and forth

between the messages “rEV XXXX” and “Press

EntR”. (If a defective card is being used the Display

will blink the message “bAd CArd”. Turn start-stop

switch OFF and remove the card.)

5. Press the ENTER key on the keypad.

6. The Display will show the message “Pro SoFt.” This

message will last for up to one minute.

7. The Display module will read “Pro donE” when the

software loading has loaded. (If a problem occurs

while loading the software: the Display will blink the

message “Pro FAIL” or “bad 12V”. Turn start-stop

switch OFF and remove the card.)

8. Turn unit OFF, via start-stop switch (ST).

9. Remove the programming card from the program-

ming/software port and return the unit to normal op-

eration by placing the start-stop switch in the ON

position.

b. Procedure for loading Configuration Software

1. Turn unit OFF using start-stop switch (ST).

2. Insert the programming card, for Configuration Soft-

ware, into the programming/software port. (See

Figure 6-20.)

3. Turn unit ON using start-stop switch (ST).

4. The Display module will show “nt40” on the left LCD

display and “531###” on the right LCD display. “###”

will indicate the dash number for a given unit model

number, use the UP or DOWN ARROW key to scroll

through the list to obtain the proper model dash num-

ber. For example, to program a model number

69NT40-531-05, press the UP or DOWN ARROW

key until the right display shows “nt40” on the right

display and “53105” on the left. (If a defective card is

being used, the Display will blink the message “bAd

CArd”. Turn start-stop switch OFF and remove the

card.)

5. Press the ENTER key on the keypad.

6. When the software loading has successfully com-

pleted, the Display will show the message “EEPrM

donE.” (If a problem occurs while loading the soft-

ware, the Display will blink the message “Pro FAIL”

or “bad 12V.” Turn start-stop switch OFF and remove

the card.)

7. Turn unit OFF using start-stop switch (ST).

8. Remove the programming card from the program-

ming/software port and return the unit to normal op-

eration by placing the start-stop switch in the ON

position.

6.20.4 Removing and Installing a Module

a. Removal:

1. Disconnect all front wire harness connectors and

move wiring out of way.

2. The lower controller mounting is slotted, loosen the

top mounting screw (see Figure 6-20) and lift up and

out.

3. Disconnect the back connectors and remove mod-

ule.

4. When removing the replacement module from its

packaging , note how it is packaged. When returning

the old module for service, place it in the packaging

in the same manner as the replacement. The pack-

aging has been designed to protect the module from

both physical and electrostatic discharge damage

during storage and transit.

b.Installation:

Install the module by reversing the removal steps.

Torque values for mounting screws (item 2, see

Figure 6-20) are 0.23 mkg (20 inch-pounds). Torque

value for the connectors is 0.12 mkg (10 inch-pounds).

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...