T-375

5–6

1. Check all connections for mechanical tightness. Be sure the air cleaner outlet pipe is not fractured.

2. In case of leakage, if adjustment does not correct the problem, replace necessary parts or gaskets. Swollen

or distorted gaskets must always be replaced.

Air Filter Indicator

The air filter indicator, used with the dry element filter, is mounted on the unit frame and connected to the engine air

intake. Its function is to indicate when the air cleaner dry element needs to be replaced. In operation: When a

plugged air cleaner decreases intake manifold pressure to 500 mm WG, the indicator moves to the red line. The air

cleaner element should be replaced and the indicator reset by pressing the reset button.

Air Cleaner, Dry Element Service

See

1. Stop the engine and open the cap clamps to remove air cleaner bottom cap.

2. Remove the air filter element from the air cleaner body.

3. Install the new element, secure the bottom cap with the cap clamps.

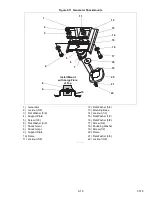

Figure 5.2 Air Cleaner, Dry Element

1) Air Outlet

2) Air Cleaner Body

3) Air Inlet

4) Cap Clamp

5) Air Outlet

6) Air Filter Indicator

- - - - -

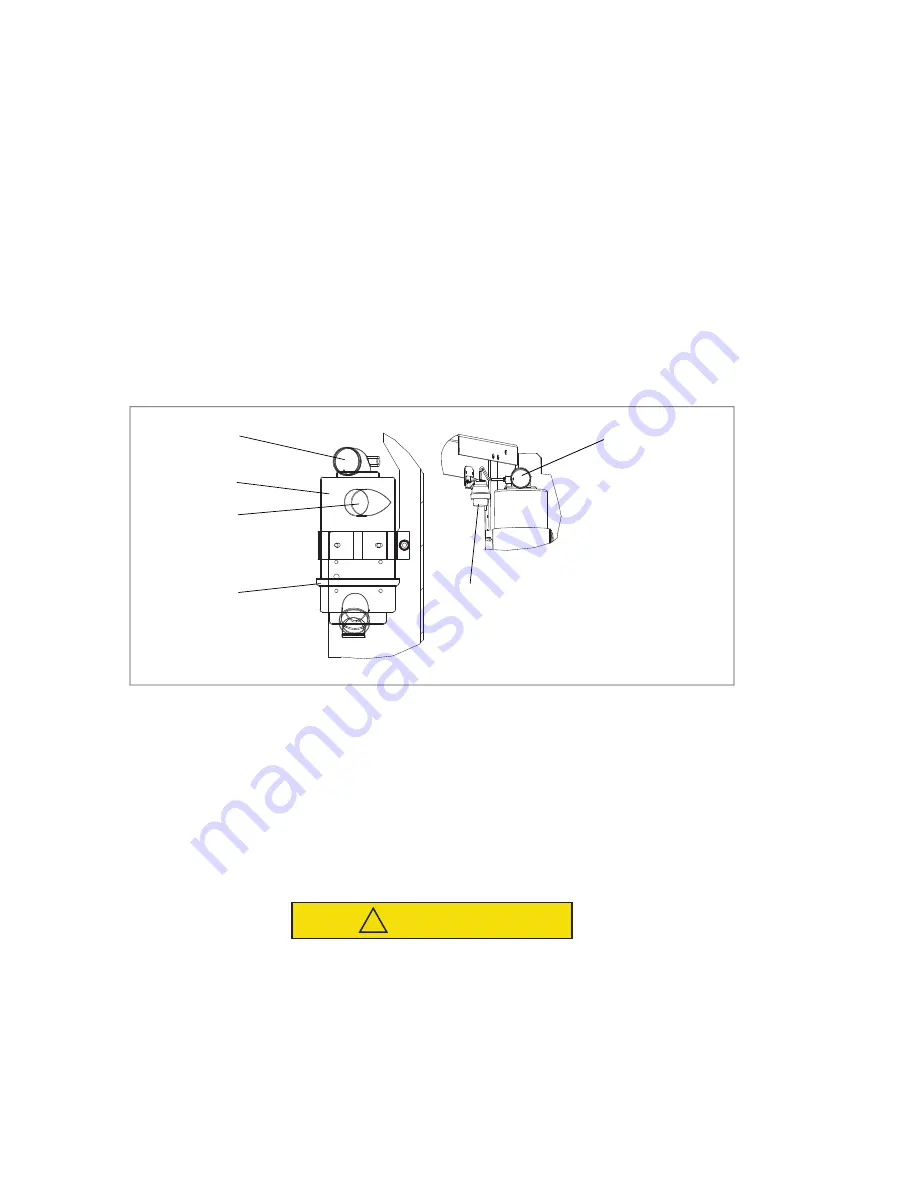

Air Cleaner, Oil Bath Service

See

The oil cup should be inspected during pretrip, before each trip. Never allow more than 12.7 mm of dirt deposit in

the cup. More than 12.7 mm accumulation could result in oil and dirt carrying over into the engine, causing

accelerated engine wear. Heavily contaminated oil will not allow the air cleaner to function properly.

CAUTION

!

Always cover the engine inlet tube while the air cleaner is being serviced.

1. Stop the engine and remove the oil cup from the air cleaner. Dispose of the oil in an environmentally safe

manner.

2. Remove the inner oil cup from the oil cup and clean both cups.

3. Reassemble and fill both oil cups to the indicated level with oil specified in

1

5

6

4

2

3

Summary of Contents for 69UG15

Page 2: ......

Page 4: ......

Page 12: ......

Page 32: ......

Page 40: ......

Page 58: ......

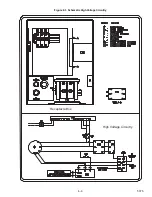

Page 60: ...T 375 6 2 Figure 6 2 Schematic for 12 VDC Control Circuit 12 VDC Control Circuit ...

Page 61: ...6 3 T 375 Figure 6 3 Schematic High Voltage Circuitry High Voltage Circuitry Receptacle Box ...

Page 62: ......

Page 65: ......