5–17

T-375

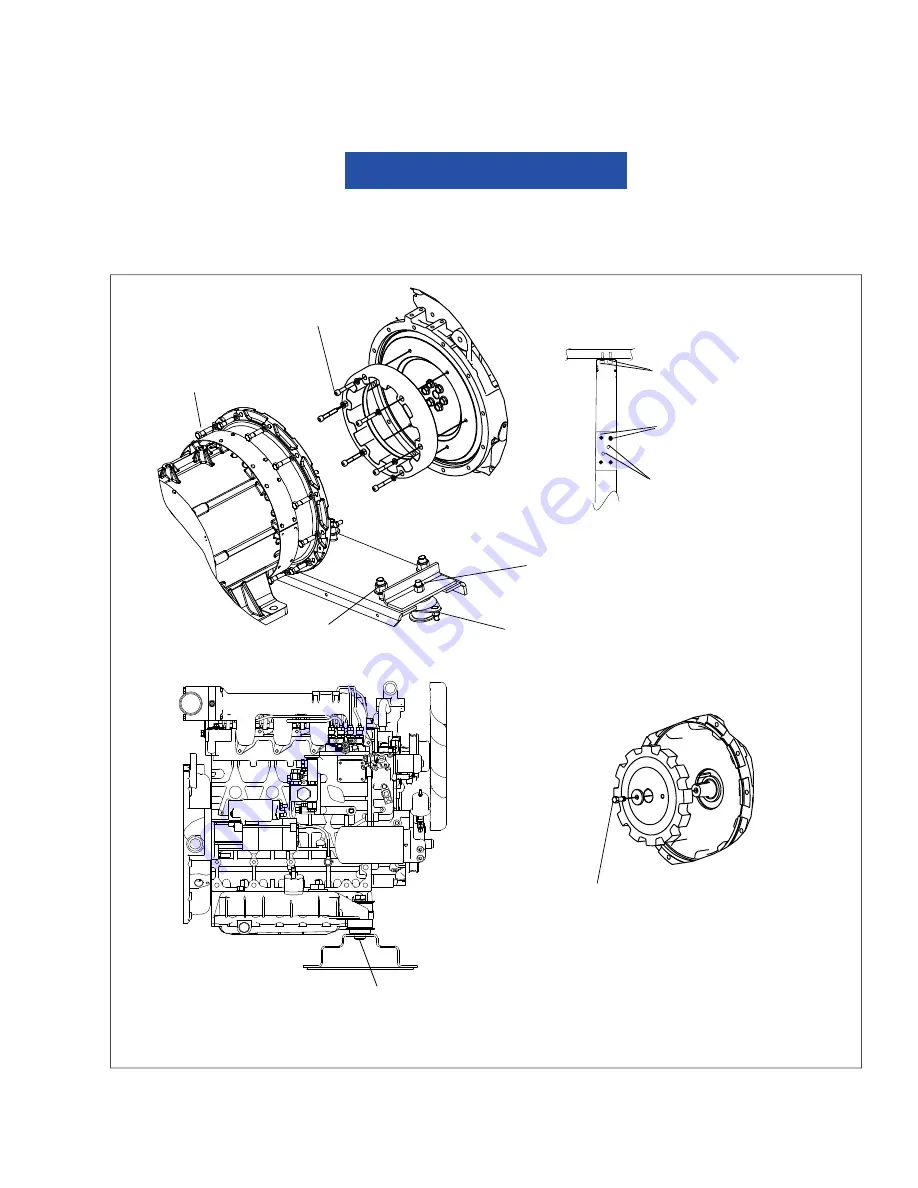

5.7 Unidrive Torque Requirements

Extensive damage may occur if the proper hardware is not used and/or proper procedures are not followed when

working with the unidrive assembly. Periodic inspection of hardware and bolt torque is recommended to ensure the

integrity of the unidrive. Torque value and hardware requirements for unidrive assembly are provided in

.

NOTICE

SST is an abbreviation for 300 Series Corrosion Resistant Steel. Loctite #242 or an equivalent

product should be used on ALL hardware shown in

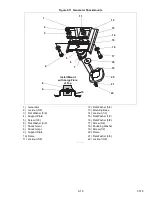

Figure 5.14 Unidrive Torque Requirements

Truss and Isolator

1/2-13 x 3-1/2 lg - SST

(2 req’d) 101.69 Nm (75 ft-lb)

3/8-16 x 1 lg - SST

(4 req’d) 33.90 Nm (25 ft-lb)

3/8 x 1.5 lg - SST

(12 req’d) 33.90 Nm (25 ft-lb)

5/8-18 x 2.00 lg - SST

(4 req’d) 123.38 - 128.80 Nm

(91-95 ft-lb)

Nut, Self Lock 3/8-16 - SST

(2 req’d) 40.67-52.88 Nm (30-39 ft-lb)

M8 x 1-1/4 lg - STL

(4 req’d) 14.91 Nm (11 ft-lb)

3/8-16 x 1-1/4 lg - SST

(4 req’d) 40.67-52.88 Nm

(30-39 ft-lb)

Torsional Dampener

5/8-11 x 4.00 lg - SST

(2 req’d) 122.02 Nm (90 ft-lb)

M8 x 50 mm Allen

(6 req’d ) 25.76 Nm (19 ft-lb)

3/8-24 x 1.00

(1 req’d) 37.96 Nm (28 ft-lb)

Summary of Contents for 69UG15

Page 2: ......

Page 4: ......

Page 12: ......

Page 32: ......

Page 40: ......

Page 58: ......

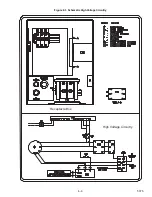

Page 60: ...T 375 6 2 Figure 6 2 Schematic for 12 VDC Control Circuit 12 VDC Control Circuit ...

Page 61: ...6 3 T 375 Figure 6 3 Schematic High Voltage Circuitry High Voltage Circuitry Receptacle Box ...

Page 62: ......

Page 65: ......