5–5

T-375

3. Apply Teflon thread sealer to the threads of the new LOP switch.

4. Install the new LOP switch.

5. Reconnect harness connection to the low oil pressure switch.

5.4.8

Engine Speed

1. The engine speed is electronically controlled.

NOTICE

Do not attempt to adjust engine speed.

5.4.9

Replacing the Engine Speed Sensor

1. Disconnect the plug to the sensor.

2. Remove the bolt securing the sensor to the housing.

3. Remove the sensor from the housing.

4. Clean the recess in the housing to ensure that the sensor seats properly when re-installed.

5. Re-install the sensor, replace the securing bolt and connect the plug to the sensor.

5.4.10

Servicing Poly V-belt

WARNING

!

Beware of moving poly V-belt and belt driven components.

WARNING

!

Beware of pinch points.

NOTICE

A frayed, cracked or worn poly V-belt must be replaced. After installing a new belt, check the

adjustment after running the unit for three or four hours. This will allow for the initial stretch,

which is common on new belts. Once this initial stretch has taken place, the belt should be

checked at regular intervals.

The poly V-belt is driven by a sheave on the engine crankshaft. Its two functions are: (1) to drive the radiator fan

and (2) to drive the water pump. To replace the poly V-belt, perform the following steps:

1. Using the proper size socket, slowly rotate the crank on the crank pulley nut. At the same time, use a flat,

blunt object to guide the belt off the crank pulley towards radiator. Be careful not to damage grooves on the

pulley.

2. Replace the poly V-Belt by positioning the belt on the water pump pulley, and while rotating the engine (as in

step 1.), use a flat, blunt object to guide the belt onto the crank pulley. Be careful not to damage grooves on

the pulley or belt.

5.4.11

Engine Air Cleaner

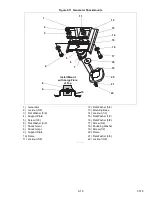

The dry element engine air cleaner uses a dry element filter (see

) to filter the engine intake air. The oil

bath air cleaner option uses an oil cup instead of the dry element filter (see

).

The engine air cleaner should be inspected regularly for leaks (see

). A damaged air cleaner or hose

can seriously affect the performance and life of the engine. The air cleaner is designed to effectively remove

contaminants from the air stream entering the engine. An excessive accumulation of contaminants in the air

cleaner will impair its operation. Therefore, a service schedule must be set up and followed.

Summary of Contents for 69UG15

Page 2: ......

Page 4: ......

Page 12: ......

Page 32: ......

Page 40: ......

Page 58: ......

Page 60: ...T 375 6 2 Figure 6 2 Schematic for 12 VDC Control Circuit 12 VDC Control Circuit ...

Page 61: ...6 3 T 375 Figure 6 3 Schematic High Voltage Circuitry High Voltage Circuitry Receptacle Box ...

Page 62: ......

Page 65: ......