5-3

62-10848

5.2

Belt Maintenance and Adjustment

WARNING

!

Beware of V-belt and belt-driven compo-

nents as the unit may start automatically.

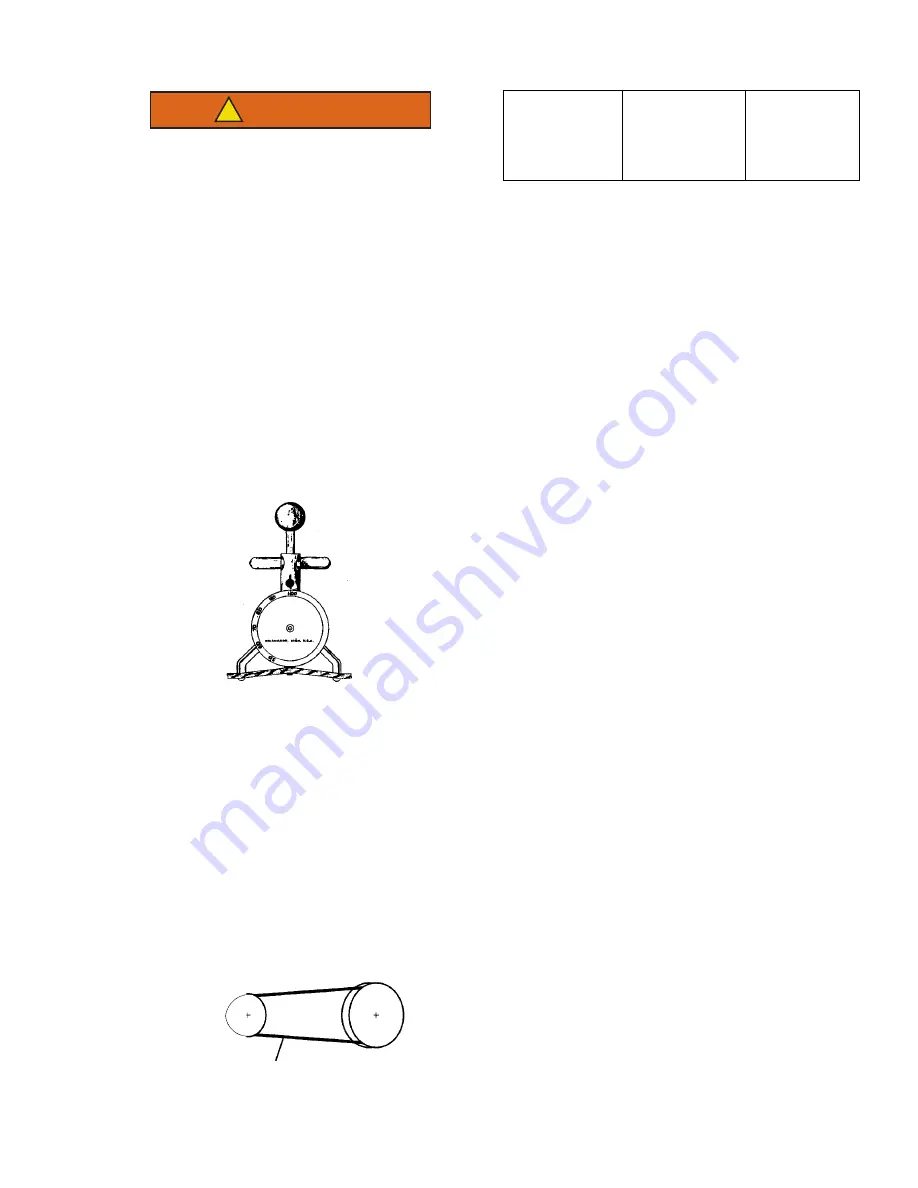

A belt tension gauge provides an accurate and easy

method of adjusting belts to their proper tension. Prop-

erly adjusted belts give long lasting and efficient service.

Too much tension shortens belt and bearing life, and too

little tension causes slippage and excessive belt wear. It

is also important to keep belts and sheaves free of any

foreign material which may cause the belts to slip.

The Belt Tension gauge can be used to adjust all belts.

The readings which we specify for Carrier Transicold

units are applicable only for our belts and application,

as the tension is dependent on the size of the belt and

distance between sheaves. When using this gauge, it

should be placed as close as possible to the midpoint

between two sheaves.

Figure 5.1 Belt Tension Gauge

Belt tension depends on each kit. Refer to Installation

Instructions provided with the kit for belt tension

requirements. In each kit installation instruction, we

indicate the belt tension (given with belt tension gauge

P/N 07-00203-00.

When installing a new V-belt the tension should be

somewhat higher than specified and readjusted after

allowing the unit to run for some time.

Figure 5.2 Layout of V-Belt

5.2.1

Standby Motor-Compressor V-Belt

a. Loosen the retaining bolts of the standby motor

support plate.

b. Replace the V-belt. Position the motor to correct

belt tension. Tighten the motor retaining bolts.

5.3

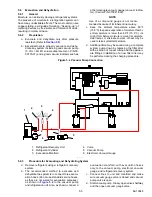

Installing R-134A Manifold Gauge Set

A R-134a manifold gauge/hose set with self-sealing

hoses is required for service of models covered within

this manual. The manifold gauge/hose set is available

from Carrier Transicold. (Carrier Transicold P/N 07-

00294-00, which includes items 1 through 6,

). To perform service using the manifold gauge/hose

set, do the following:

5.3.1

Preparing Manifold Gauge/Hose Set For

Use

a. If the manifold gauge/hose set is new or was

exposed to the atmosphere it will need to be

evacuated to remove contaminants and air as

follows:

b. Back seat (turn counterclockwise) both field ser-

vice couplers (see

) and midseat both

hand valves.

c. Connect the yellow hose to a vacuum pump and

an R-134a cylinder.

d. Evacuate to 10 inHg (254 mmHg) and then

charge with R-134a to a slightly positive pres-

sure of 1.0 psig (0.07 Bar).

e. Front seat both manifold gauge set hand valves

and disconnect from cylinder. The gauge set is

now ready for use.

5.3.2

Connecting Manifold Gauge/Hose Set

To connect the manifold gauge/hose set for reading

pressures, do the following:

a. Remove access valve cap.

b. Connect the field service coupler (see

) to the access valve.

c. Turn the field service coupling knob clockwise,

which will open the system to the gauge set.

d. Read system pressures.

e. Repeat the procedure to connect the other side

of the gauge set.

Carrier Part Number 07-00203-00

Standby

Motor

Compressor

Standby Motor/Compressor V-Belt

Table 5–3 Belt Tension (See

)

BELTS

New Install

Tension

Running

Tension

Standby Motor

to Compressor

90 ft./lbs

(122 Nm)

80 to 90 ft./lbs

(108 to 122 Nm)