62-10848

5-4

5.3.3

Removing the Manifold Gauge Set

1. While the compressor is still ON, backseat the

high side service valve.

2. Midseat both hand valves on the manifold

gauge set and allow the pressure in the mani-

fold gauge set to be drawn down to low side

pressure. This returns any liquid that may be in

the high side hose to the system.

CAUTION

!

To prevent trapping liquid refrigerant in

the manifold gauge set, be sure set is

brought to suction pressure before dis-

connecting.

3. Backseat the low side service valve. Backseat

both field service couplers and frontseat both

manifold set hand valves. Remove the couplers

from the access valves.

4. Install both service valve stem caps and access

valve caps (finger-tight only).

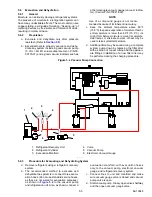

Figure 5.3 Manifold Gauge Set (R-134A)

1. Manifold Gauge Set

2. Hose Fitting (0.5-16 Acme)

3. Refrigeration and/or Evacuation Hose (SAE J2196/

R-134a)

4. Hose Fitting w/O-ring (M14 x 1.5)

5. High Side Field Service Coupler

6. Low Side Field Service Coupler

5.4

Removing the Refrigerant Charge

NOTE

To avoid damage to the earth’s ozone layer,

use a refrigerant recovery system whenever

removing refrigerant.

Connect a refrigerant recovery system (Carrier P/N

MVS-115-F-L-CT (115V) or MVS-240-F-L-CT (240V))

to the unit to remove refrigerant charge. Refer to

instructions provided by the manufacturer of the refrig-

erant recovery system.

5.4.1

Refrigerant Removal From a Non-Working

Compressor

To remove the refrigerant from a compressor that is not

operational, do the following:

a. Attach a manifold gauge set as shown in

b. Recover refrigerant with a refrigerant recovery

system.

c. Service or replace components as required and

leak check the entire system. (See

5.5

Refrigerant Leak Checking

A refrigerant leak check should always be performed

after the system has been opened to replace or repair

a component. To check for leaks in the refrigeration

system, perform the following procedure:

NOTE

Use only R-134A to pressurize the system.

Any other gas or vapor will contaminate the

system which will require additional purging

and evacuation of the high side (discharge)

of the system.

a. If system is without refrigerant, charge system

with refrigerant to build up pressure between 30

to 50 psig (2 to 3.4 Bars). Remove refrigerant

cylinder and leak check all connections.

b. Add sufficient nitrogen to raise system pressure

to 150 to 200 psig (10.21 to 13.61 bar).

c. Check for leaks. The recommended procedure for

finding leaks in a system is with an electronic leak

detector. (Carrier P/N 07-00295-00). Testing joints

with soap suds is satisfactory for locating large

leaks but be necessary when an electronic leak

detector will not function correctly.

d. Remove refrigerant using a refrigerant recovery

system and repair any leaks. Evacuate and

dehydrate the unit. (Refer to

)

Charge unit with refrigerant. (Refer to

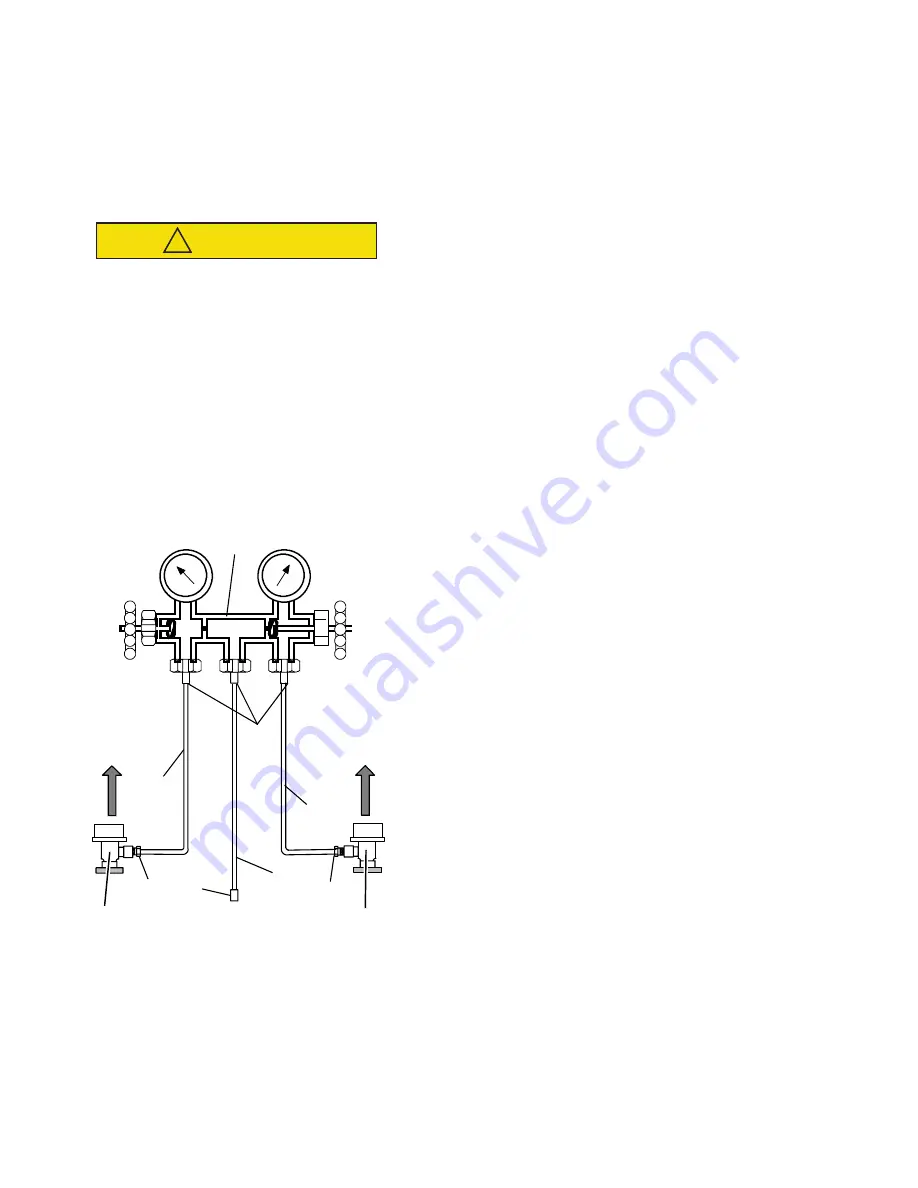

Low Pressure

Gauge

High Pressure

Gauge

Opened

(Backseated)

Hand Valve

Closed

(Frontseated)

Hand Valve

To Low Side

Access Valve

To High Side

Access Valve

BLUE

RED

YELLOW

(Blue Knob)

(Red Knob)