62-10848

5-6

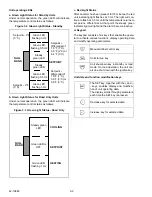

e. Evacuate unit until the electronic vacuum gauge

indicates 2000 microns. Close the electronic

vacuum gauge and vacuum pump valves. Shut

off the vacuum pump. Wait a few minutes to be

sure the vacuum holds.

f. Break the vacuum with clean dry nitrogen. Raise

system pressure to approximately 2 psig (0.14 Bar).

g. Purge nitrogen from system.

h. Repeat steps e through g one time.

i. Evacuate unit to 500 microns. Close off vacuum

pump valve and stop pump. Wait five minutes to

see if vacuum holds. This checks for residual

moisture and/ or leaks.

j. With a vacuum still in the unit, the refrigerant

charge may be drawn into the system from a

refrigerant container on a scale. The correct

amount of refrigerant may be added by observ-

ing the scale. (Refer to

5.7

Charging the Refrigeration System

5.7.1

Checking The Refrigerant Charge

a. Start unit in cooling mode and run for approxi-

mately ten minutes.

b. Partially block off air flow to condenser coil so

discharge pressure rises to 174 psig (12 Bars).

c. The unit is correctly charged when there are no

bubbles in the sight glass.

5.7.2

Installing a Complete Charge

NOTE

It may be necessary to finish charging the

unit using the partial charge method, due to

pressure rise in the high side of the system.

(Refer to

)

a. Dehydrate unit and leave in deep vacuum.

(Refer to

)

b. Place refrigerant cylinder on scale and connect

charging line from cylinder to receiver outlet

(king) valve. Purge charging line at outlet valve.

c. Note weight of refrigerant cylinder.

d. Open liquid valve on refrigerant cylinder. Open

king valve half way and allow the liquid refriger-

ant to flow into the unit until the correct weight of

refrigerant has been added as indicated by

scale. Correct charge will be found in

.

NOTE

It is possible that all liquid may not be pulled

into the receiver, as outlined in step d.

above. In this case, vapor charge remaining

refrigerant through the suction service port

(See

).

e. When refrigerant cylinder scale indicates that the

correct charge has been added, close the liquid

line valve on cylinder and backseat the king valve.

f. Replace all valve caps.

g. Start unit and check for non-condensables.

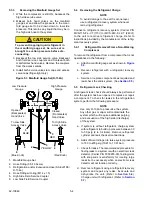

5.7.3

Adding a Partial Charge

NOTE

When partially charging the refrigeration sys-

tem with R-134A, install a vapor charge.

a. Place refrigerant cylinder on scale and connect

charging line between suction port and refriger-

ant cylinder.

b. Note weight of refrigerant cylinder.

c. Run unit on high speed cool and open cylinder

vapor valve.

d. If necessary, partially block off air flow to con-

denser coil so discharge pressure rises to 174

psig (12 Bars).

e. The unit is correctly charged when there are no

bubbles in the sight glass.

f. Start unit and check for non-condensables.

5.8

Checking for Non-Condensables

To check for non-condensables, proceed as follows:

a. Stabilize system to equalize pressure between

the suction and discharge side of the system.

b. Check temperature at the condenser and receiver.

c. Check pressure at the receiver outlet (King) valve.

d. Check saturation pressure as it corresponds to

the condenser/receiver temperature using the

Temperature- Pressure Chart,

e. If gauge reading is 3 psig (0.2 Bar) or more than

the calculated P/T pressure in step d., non-con-

densables are present.

f. Remove refrigerant using a refrigerant recovery

)

g. Evacuate and dehydrate the system. (Refer to

)

h. Charge the unit. (Refer to

)

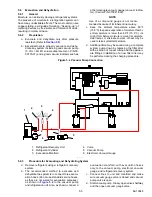

5.9

Replacing the Compressor

5.9.1

Removing Compressor

WARNING

!

Ensure power to the unit is OFF, power

plug is disconnected and circuit breaker

is open or vehicle engine is OFF and neg-

ative battery cable is connected before

replacing compressor.

a. Remove the refrigerant. (See

).

WARNING

!

Slowly open the plug on the suction and

discharge valves of the new compressor

to vent the nitrogen holding charge.

b. Remove bolts from flanges.