6-5

62-10848

6.2.9

Cab Command Malfunction

Cab Command non-operational

Fuse open

Replace

Microprocessor malfunction

Replace

Microprocessor/Cab command cable

Check

6.2.10

No Evaporator Air Flow or Restricted Air Flow

Evaporator coil blocked

Heavy frost on coil

Check

Coil dirty

No or partial evaporator air flow

Evaporator fan loose or defective

Check

Evaporator fan rotating backwards

Check

Evaporator air flow blocked in refrigerated compartment

Check

Fan motor(s) malfunction

Replace

6.2.11

Expansion Valve

Low suction pressure with high

superheat

Low refrigerant charge

External equalizer line plugged

Repair

Broken capillary

Repair

Superheat setting too high

Low superheat and liquids lugging

in compressor

Superheat setting too low

External equalizer line plugged

Repair

Pin and seat of expansion valve eroded or held open by

foreign material

Fluctuating suction pressure

Improper bulb location or installation

Insulation missing from sensing bulb

Replace

Low superheat setting

High superheat

Expansion Valve setting

6.2.12

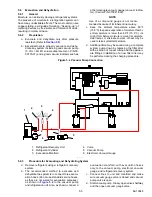

Malfunction Hot Gas Solenoid or Condenser Pressure Regulating Valve

Valve does not function properly

No power to valve

Check

Improper wiring or loose connections

Check

Valve improperly assembled

Coil or coil sleeve improperly assembled

Movement of plunger restricted due to:

a. Corroded or worn parts

b. Foreign material lodged in valve

c. Bent or dented enclosing tube

Valve shifts but refrigerant

continues to flow

Foreign material lodged under seat

Defective seat

6.2.13

Standby Compressor Malfunction

Standby compressor fails to start

Motor contactor defective

Replace

Motor Overload open

Check

Improper power supply

Correct

5-minute timer active

Check

Standby motor starts, then stops

Motor Overload open

Check

Table 6–2 Mechanical Indications (Continued)

Indication/Trouble

Possible Causes

Reference

Section