2-11

62-10848

2.8

Refrigerant Circuit

2.8.1

Cooling

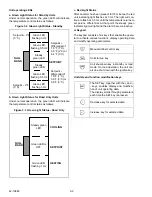

(See

When cooling, the unit operates as a vapor compres-

sion refrigeration system. The main components of the

system are the reciprocating compressor, air-cooled

condenser, thermostatic expansion valve and the direct

expansion evaporator.

The compressor raises the pressure and temperature of

the refrigerant and forces it through the discharge check

valve and condenser pressure control valve into the

condenser tubes. The discharge check valves prevent

reverse flow through the non operating compressor.

When operating on the road compressor, the flow also

passes through the oil separator where oil is removed

and returned to the road compressor.

The condenser fan circulates surrounding air over the

outside of the condenser tubes. Heat transfer is thus

established from the refrigerant gas (inside the tubes)

to the condenser air (flowing over the tubes). The con-

denser tubes have fins designed to improve the trans-

fer of heat. This removal of heat causes the refrigerant

to liquefy. Liquid refrigerant flows from the condenser

to the receiver.

The receiver stores the additional charge necessary for

low ambient operation and for heating and defrost

modes.

The refrigerant leaves the receiver and flows through a

manual receiver shut-off valve (king valve).

The refrigerant then flows through a check valve. The

check valve serves to prevent reverse flow of refriger-

ant during the heating/defrost cycle.

The refrigerant then flows through the filter drier, where

an absorbent keeps it dry and clean. The refrigerant

then flows though a sight glass. The sight glass is fitted

with an indicator that changes color to indicate mois-

ture content of the refrigerant. The refrigerant then

flows through the subcooler which removes additional

heat from the liquid to improve system efficiency.

The liquid than enters the thermostatic expansion valve

(with external pressure equalizer) which regulates the

flow rate of refrigerant towards the evaporator in order

to obtain maximum use of the evaporator heat transfer

surface.

The evaporator tubes have aluminum fins to increase

heat transfer; therefore heat is removed from the air

circulating through the evaporator. This cold air is circu-

lated throughout the truck to maintain the cargo at the

desired temperature.

The transfer of heat from the air to the low temperature

liquid refrigerant causes the liquid to vaporize. The

vapor at low temperature and is then drawn out by the

compressor. From this point, the cycle starts over.

On 115v units the refrigerant then enters the compres-

sor regulating valve (CPR) which regulates refrigerant

pressure entering the compressor. The cycle then

starts over.

The quench valve opens as required to maintain a

maximum discharge temperature. (Refer to

for settings.)

2.8.2

Heat And Defrost

When refrigerant vapor is compressed to a high pres-

sure and temperature in a compressor, the mechanical

energy necessary to operate the compressor is trans-

ferred to the gas as it is being compressed. This

energy is referred to as the “heat of compression” and

is used as the source of heat during the heating or

defrost cycle.

When the microprocessor activates heating or defrost,

the hot gas solenoid valve energizes and the con-

denser pressure control valve energizes, closing the

port to the condenser and opening a port which allows

heated refrigerant vapor to flow directly to the evapora-

tor coil.

The main difference between heating and defrosting is

that when in heating mode the evaporator fans con-

tinue to run thus circulating the air throughout the truck

to heat the product. When in defrost, the evaporator

fans stop, thus allowing the heated vapor to defrost any

ice build-up on the coil.

When the pressure is above the setting of the con-

denser pressure control switch, the condenser pres-

sure control valve (HGS2) is closed to prevent

additional pressure rise in the system. When pressure

is below the setting of the condenser pressure control

switch, the valve is opened to pressurize the receiver

and force additional refrigerant into the system and

increase heating capacity.