5-5

62-10848

5.6

Evacuation and Dehydration

5.6.1

General

Moisture can seriously damage refrigerant systems.

The presence of moisture in a refrigeration system can

have many undesirable effects. The most common are

copper plating, acid sludge formation, “freezing-up” of

metering devices by free water, and formation of acids,

resulting in metal corrosion.

5.6.2

Preparation

a. Evacuate and dehydrate only after pressure

leak test. (Refer to

)

b. Essential tools to properly evacuate and dehy-

drate any system include a good vacuum pump

(5 cfm = 8m#H volume displacement, P/N07-

00176-01) and a good vacuum indicator such as

a thermocouple vacuum gauge (vacuum indica-

tor). (Carrier P/N 0700414-00).

NOTE

Use of a compound gauge is not recom-

mended because of its inherent inaccuracy.

c. Keep the ambient temperature above 60°F

(15.6°C) to speed evaporation of moisture. If ambi-

ent temperature is lower than 60°F (15.6°C), ice

might form before moisture removal is complete.

Heat lamps or alternate sources of heat may be

used to raise system temperature.

d. Additional time may be saved during a complete

system pump down by replacing the filter drier

with a section of copper tubing and the appropri-

ate fittings. Installation of a new filter drier may

be performed during the charging procedure.

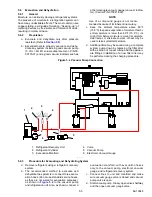

Figure 5.4 Vacuum Pump Connection

1. Refrigerant Recovery Unit

2. Refrigerant Cylinder

3. Evacuation Manifold

4. Valve

5. Vacuum Pump

6. Electronic Vacuum Gauge

- - - - -

5.6.3

Procedure for Evacuating and Dehydrating System

a. Remove refrigerant using a refrigerant recovery

system.

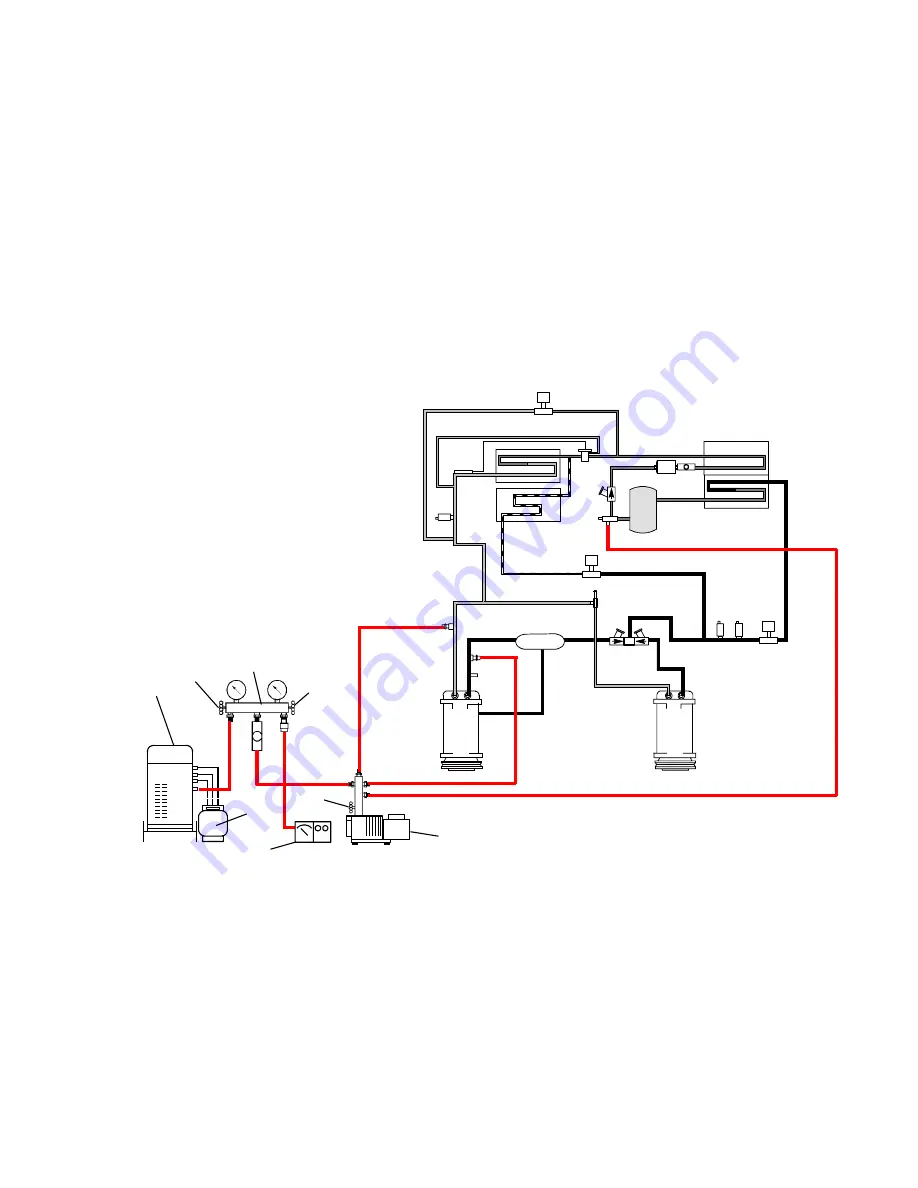

b. The recommended method to evacuate and

dehydrate the system is to connect three evacu-

ation hoses (Do not use standard service hoses,

as they are not suited for evacuation purposes.)

as shown in

to the vacuum pump

and refrigeration unit. Also, as shown, connect a

evacuation manifold, with evacuation hoses

only, to the vacuum pump, electronic vacuum

gauge, and refrigerant recovery system.

c. Connect lines to unit and manifold and make

sure vacuum gauge valve is closed and vacuum

pump valve is open.

d. Start vacuum pump. Slowly open valves halfway

and then open vacuum gauge valve.