5-9

62-10848

Figure 5.8 Compressor Pressure Regulating Valve

5.14 Adjusting the Compressor Pressure Regulat-

ing Valve (CPR) (115V Only)

When adjusting the compressor pressure regulating

valve (CPR) (see

), the unit must be running

in heating or defrost mode. This will ensure a suction

pressure above the proper CPR setting. To adjust the

CPR valve, proceed as follows:

a. Install a gauge on the suction line.

b. Remove cap from CPR valve.

c. With an 8 mm Allen wrench, loosen the jam nut.

d. Using the 8 mm Allen wrench, adjust the set

screw. To raise the suction pressure, turn the set

screw clockwise; to lower the suction pressure,

turn counterclockwise. Refer to

for CPR valve setting.

e. When the setting has been adjusted, tighten the

jam nut securely against the set screw. This will

prevent any movement of the set screw due to

vibrations in the unit. Replace the cap.

5.15 Thermostatic Expansion Valve

The thermal expansion valve is an automatic device

which maintains constant superheat of the refrigerant

gas leaving the evaporator regardless of suction pres-

sure. The valve functions are: (a) automatic response

of refrigerant flow to match the evaporator load and (b)

prevention of liquid refrigerant entering the compres-

sor. Unless the valve is defective, it seldom requires

any maintenance.

NOTE

Due to the time involved in adjusting the

superheat, replace the valve rather than

adjusting it.

5.15.1

Replacing expansion valve

a. Remove refrigerant charge (See

b. Remove insulation from expansion valve bulb

and then remove bulb from suction line.

c. Loosen flare nut and disconnect equalizer line

from expansion valve.

d. The txv bulb is located below the center of the

suction line. This area must be clean to ensure

positive bulb contact. Strap bulb to suction line

and insulate both.

e. Braze the equalizer tubes to expansion valve.

f. Evacuate, dehydrate and recharge unit. (See

and

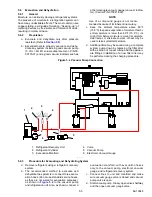

5.15.2

Measuring Superheat

a. Remove insulation from expansion valve bulb

b. Loosen one TXV bulb clamp and make sure

area under clamp (above TXV bulb) is clean.

c. Place thermocouple above (parallel to) the TXV

bulb and then secure loosened clamp making

sure both bulbs are firmly secured to suction line

as shown in

d. Connect an accurate gauge to the ¼” port on

the suction service valve.

e. Run unit until stabilized at - 4°F (- 20°C) refriger-

ated compartment temperature.

f. From the temperature/pressure chart (

), determine the saturation temperature corre-

sponding to the evaporator outlet pressure.

g. Note the temperature of the suction gas at the

expansion valve bulb.

h. Subtract the saturation temperature determined

in Step f. from the average temperature mea-

sured in Step g. The difference is the superheat

of the suction gas. Refer to

for

superheat setting.

i. If required, adjust superheat by turning the

adjusting screw located under the cap on the

side of the valve.

Figure 5.9

Thermostatic Expansion Valve Bulb and

Thermocouple

1. Suction Line (end view)

2. TXV Bulb Clamp

3. TXV Bulb

4. Thermocouple

5. Nut and Bolt (Clamp)

Set Screw

Jam Nut

Cap