6-1

62-10848

SECTION 6

Troubleshooting

WARNING

!

Beware of unannounced starting of the unit. The unit may cycle the fans and operating com-

pressor unexpectedly as control requirements dictate. Press OFF key on the cab command,

turn vehicle engine off or disconnect power plug and open circuit breaker.

CAUTION

!

Under no circumstances should anyone attempt to service the microprocessor module and

cab command. Should a problem develop with the control system, contact your nearest Carrier

Transicold dealer for replacement components.

6.1

Introduction

Under normal circumstances, unit problems will be indicated by an active alarm in the alarm list. Suggested trou-

bleshooting actions for each alarm indication are provided in

. Suggested corrective actions for mechan-

ical type problems are listed under subject headings in

.

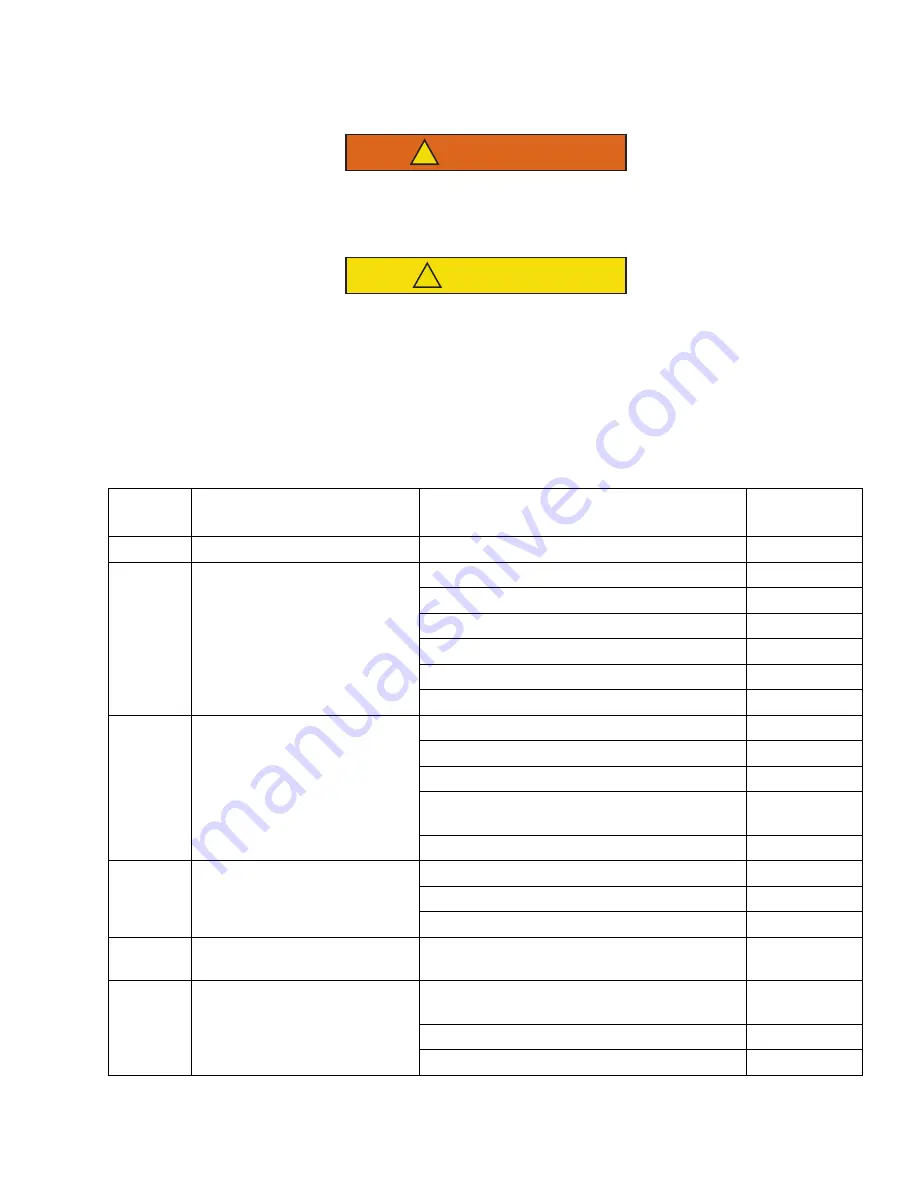

Table 6–1 Alarm Indications

Alarm

Description

Corrective Action

Reference

Section

A00

No Malfunction

All components functioning normally

--

A01

Low Pressure Switch (LP) or High

Pressure Switch (HP1) Open

(Road)

Unit undercharged

Liquid line filter drier restricted

TXV strainer plugged with foreign material/ice.

TXV malfunction

Verify operation of evaporator fans.

--

Failed switch

A02

Low Pressure Switch (LP) or High

Pressure Switch (HP1) Open

Unit overcharged

Verify operation of condenser fan

--

Non-condensibles in system

Discharge check valve failed closed (standby

only)

Replace

Failed switch

A03

Standby

Units Only

Electric motor overload

Thermal overload open in motor windings.

Current overload tripped.

Verify line voltage

A04

Road Compressor Clutch (CLHR)

Malfunction

Current draw of road clutch coil either high or low

Replace

A05

Standby

Units Only

Standby Contactor (MC) high

amp draw

Contactor coil either high or low (0.2A for 3

phase; 0.5A for 1 phase)

--

Verify plunger moves freely

--

Replace contactor

--