7–27

T-372

To confirm what caused the test to fail, perform the following additional test.

1. Connect the manifold gauge set to discharge service valve (DSV) and suction service valve (SSV).

2. Front seat the SSV and pump down the compressor.

3. Front seat the DSV valve to isolate the compressor.

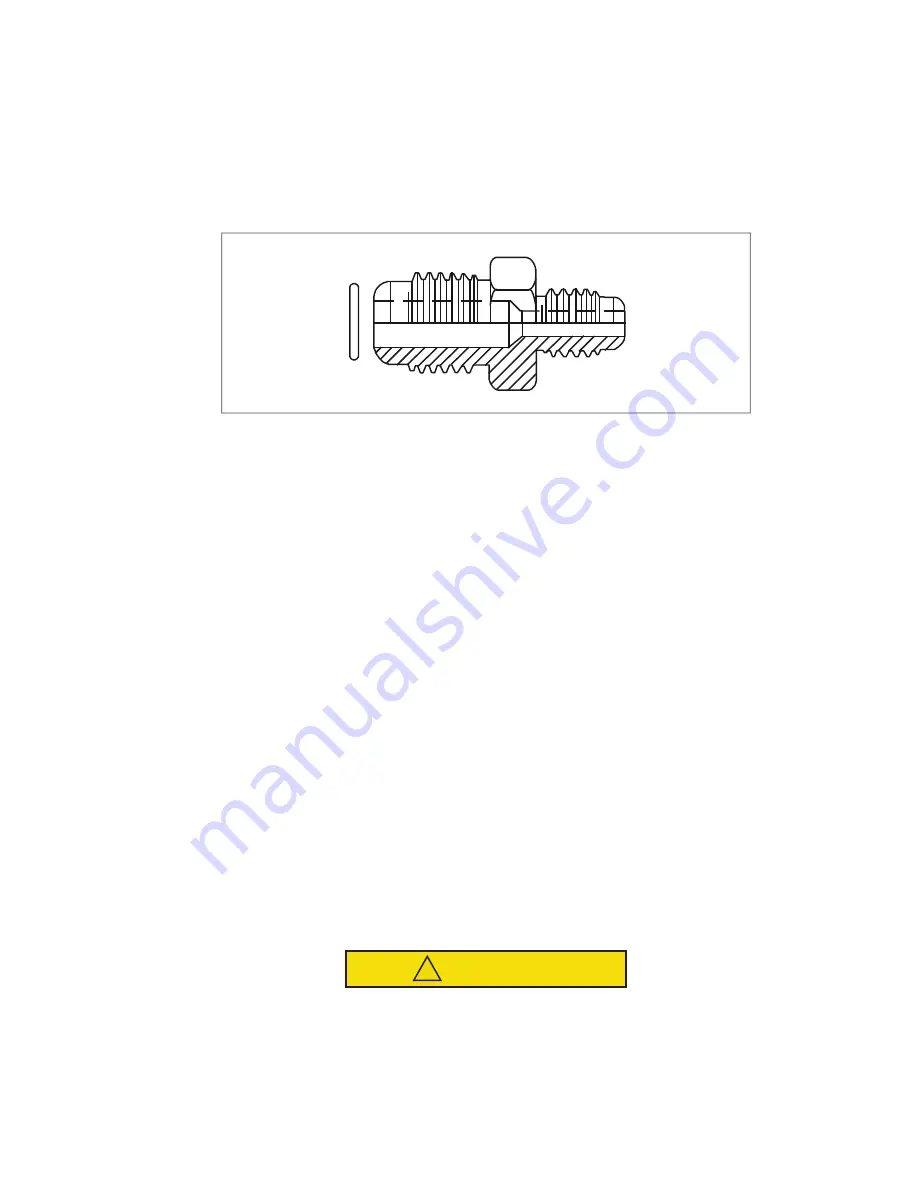

4. Disconnect the DUV from the top of compressor and install a 1/2 to 1/4 flared adapter / O-ring (P/N 40-

50076-00sv).

Figure 7.18 Adapter and O-Ring

5. Using refrigerant (R-134a or R-513A as specified for the unit model number) or Nitrogen, pressurize the line

to 50 psi (3.5 bar) at the adapter connection and close supply at the tank. Pressure should hold as the valve

is normally closed. If pressure drops, check for leaks at the installed fitting (part number 40-50076-00sv);

repair and retest. If pressure increases at the suction service valve and decreases at the pressure supply;

the valve is leaking and should be replaced. If no leak proceed to step 6.

6. Energize the DUV by removing the coil and placing a magnet on the valve stem opening the valve. If the

pressure does not increase at the SSV and decrease at the supply, replace the valve as it did not open.

If a magnet is not available, a jumper procedure can be used as follows:

1. Remove all four controller fuses (F1, F2, F3a, F3b).

2. Remove the KA6 wire from the KA controller connector on the front of the controller.

3. Disconnect the X1 wire from the 24VAC side of the transformer (black wire) and locate it away from the

transformer.

4. Jumper between the black transformer wires to the KA6 wire removed from the connector.

5. Connect power to the unit and turn the circuit breaker on. The DUV coil is now energized.

6. Pressure should drop.

7. Power the circuit breaker off, reconnect wires and reinstall fuses.

8. If the valve opens and closes properly, the failure mode is with the compressor and it should be changed at

the earliest opportunity.

7.24 Digital Unloader Valve (DUV)

7.24.1

Removing the DUV

1. Pump down the compressor (see

) and frontseat both suction and discharge valves. In the event

the DUV is stuck open and compressor cannot pump down, remove charge.

CAUTION

!

The scroll compressor achieves low suction pressure very quickly. Do not use the compressor

to evacuate the system below 0 psig. Never operate the compressor with the suction or

discharge service valves closed (frontseated). Internal damage will result from operating the

compressor in a deep vacuum.

2. Turn unit power off and remove power from the unit.

3. Loosen the bolt on top of the DUV and remove the coil assembly.

1/2”

1/4”

O-Ring