T-372

4–10

c. When the return air temperature decreases to 0.2°C (0.4°F) below setpoint, contacts TC, TS and TN are

opened to de-energize the compressor, economizer solenoid valve and condenser fan motor. The white

COOL light is also de-energized. The electronic expansion valve (EEV) will close.

d. The evaporator fan motors continue to run in low speed to circulate air throughout the container. The green

IN RANGE light remains illuminated as long as the return air is within tolerance of setpoint.

e. If return air temperature drops to 10°C (18°F) or more below setpoint, the evaporator fans switch to high speed.

f. When the return air temperature increases to 0.2°C (0.4°F) above setpoint and three minutes have elapsed,

the EEV opens and contacts TC, TS and TN close to restart the compressor, open the ESV and restart the

condenser fan motor. The white COOL light is illuminated.

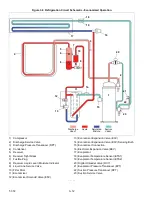

Figure 4.8 Frozen Mode

NOTE

The EEV and DUV are independently operated by the microprocessor. Complete schematics and leg

-

4.3.20

Defrost

Defrost is initiated to remove ice buildup from the evaporator coil which can obstruct air flow and reduce the cooling

capacity of the unit. The defrost cycle may consist of up to three distinct operations depending upon the reason for

the defrost or model number configuration. The first is de-icing of the coil, the second is defrost due to a probe

check cycle and the third is a snap freeze process based on the unit model configuration.

• De-icing the coil consists of removing power to the cooling components (compressor, evaporator fans, and con

-

denser fan), closing the EEV, and turning on the heaters, which are located below the evaporator coil. During

normal operation, de-icing will continue until temperatures indicate that the ice on the coil has been removed,

proper air flow has been restored, and the unit is ready to control temperature efficiently.

• If defrost was initiated by the probe check logic, then the Probe Check is carried out after the completion of the

defrost cycle. A Probe Check is initiated only when there is an inaccuracy between the controller temperature

sensors.

• Snap Freeze allows the system to cool for a period of time after de-icing, with the evaporator fans turned off and

is only carried out if configured by model number. Snap-Freeze allows for the removal of latent de-icing heat

from the evaporator coils, and freezes any remaining moisture that might otherwise be blown into the container.

For more information on Probe Diagnostics refer to

4.3.21

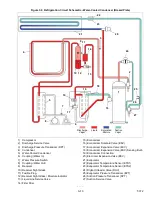

Defrost Operation

Initiation of defrost is dependent on the state of the defrost temperature sensor (DTS). When the DTS senses a

temperature less than 10°C (50°F), the defrost options become active and the timer is engaged for the initiation of

the defrost cycle. The defrost time accumulates when the compressor is running. In the perishable mode this is the

same as real time as the compressor in general runs continuously. In frozen mode the actual time necessary to

count down to the next defrost will exceed the defrost interval depending on the compressor duty-cycle.

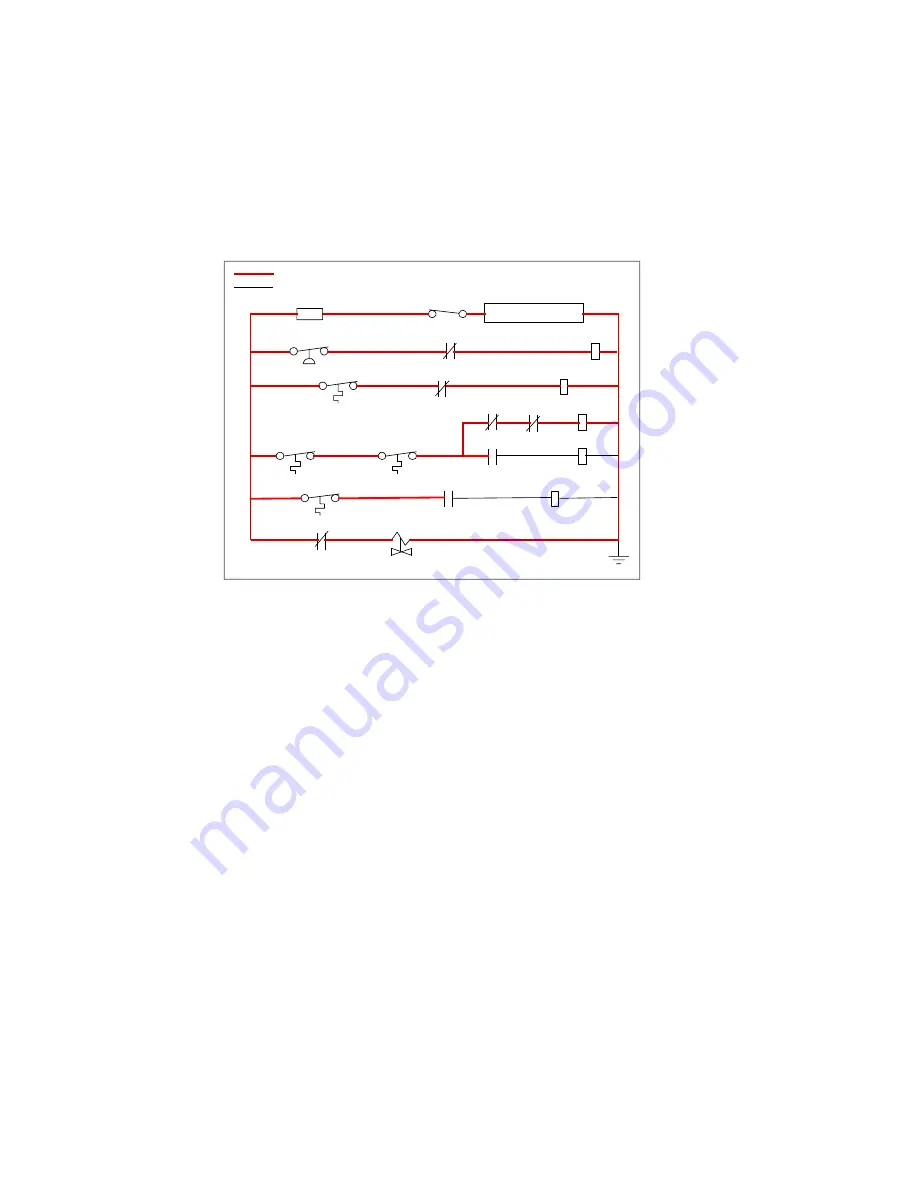

24 VOLT POWER

ENERGIZED

DE-ENERGIZED

TN

ST

F

HPS

CH

IP-CM

TC

CF

TE

IP-EM1

EF

IP-EM2

HTT

TH

HR

ESV

TS

TV

EF

ES