4–11

T-372

When the defrost mode is in the active state, defrost can be initiated when any one of the following additional con

-

ditions become true:

1.

Manually:

While in the Defrost screen, when the Manual Defrost soft key is selected, if conditions will allow

for a defrost, a manual defrost is initiated. The Defrost Indicator light is lit, and the user is brought back to

the Main / Default screen. If conditions are NOT allowing for a defrost, a pop up message screen appears.

2.

Timer:

The Defrost Interval Timer reaches the user selectable Interval. The user-selected intervals are 3, 6,

9, 12, 24 Hours, Off, AUTO, or AUTO2; factory default is AUTO. Refer to Defrost Interval setting on the Trip

Settings screen.

a. Automatic defrost starts with an initial defrost at three hours and then adjusts the interval to the next

defrost based on the accumulation of ice on the evaporator coil. Following a start-up or after termination

of defrost, the time will not begin counting down until the DTS reading falls below 10°C (50°F). If the

reading of DTS rises above termination setting any time during the timer count down, the interval is reset

and the countdown starts over. The Auto defrost time is reset to three hours start time after every PTI ini

-

tiation or trip start interval.

b. After a new Defrost Interval is selected, the previously selected Interval is used until the next defrost ter

-

mination, the next time the DTS contacts are OPEN, or the next time power to the control is interrupted.

If the previous value or the new value is “OFF”, the newly selected value will be used immediately.

3.

Probe Check:

If defrost is initiated due to Probe Check immediately following the defrost cycle the evapora

-

tion fans are started and run for eight minutes to stabilize the temperature throughout the container. A probe

check comparison is carried out at the end of the eight minute period if any sensor is found out of calibration.

At this time its alarm set is no longer used for control/reorder purposes.

4.

Probe Check Logic:

The logic determines that a Probe Check is necessary based on temperature values

currently reported by the supply and return probes

5.

Delta T Logic:

If the difference between return and supply air temperature (Delta T) becomes too great indi

-

cating possible reduced airflow over the evaporator coil caused by ice buildup requiring a defrost.

a. In Perishable Pull Down - Delta T increases to greater than 12°C, and 90 minutes of compressor run

time have been recorded.

b. In Perishable Steady State - A baseline Delta T is recorded following the first defrost cycle after steady

state conditions are reached, (the unit is cooling, and the evaporator fans and heaters must remain in a

stable state for a period of five minutes). Defrost will be initiated if Delta T increases to greater than 4°C

above the baseline, and 90 minutes of compressor run time have been recorded.

c. In Frozen Mode - Defrost will be initiated if Delta T increases to greater than 16°C and 90 minutes of

compressor run time have been recorded.

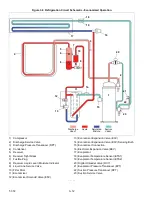

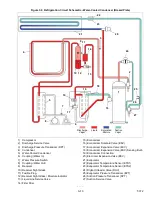

When defrost is initiated, the controller closes the EEV, opens contacts TC, TN and TE (or TV) to de-energize the

compressor, condenser fan and evaporator fans. The controller then closes contacts TH to supply power to the

heaters. The orange DEFROST light and HEAT light are illuminated and the COOL light is also de-energized.

Figure 4.9 Defrost

24 VOLT POWER

ENERGIZED

DE-ENERGIZED

TN

ST

F

HPS

PB

IP-CM

TC

CF

TE

IP-EM1

EF

IP-EM2

HTT

TH

HR

ESV

TS

TV

EF

ES