2–1

T-372

SECTION 2

INTRODUCTION

2.1 Introduction

The Carrier Transicold PrimeLINE models 69NT40-571-000 to 199 are of lightweight aluminum frame construction,

designed to be bolted onto the front of a container and serve as the container’s front wall. Forklift pockets are

provided for unit installation and removal.

The Carrier Transicold PrimeLINE ONE™ models 69NT40-575-000 to 199 are units of lightweight aluminum frame

construction, designed to be directly installed on-site onto a welded front wall of a container.

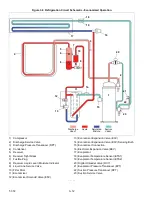

Primeline units are self-contained, all electric units, which include cooling and heating systems to provide precise

temperature control. The units are supplied with a complete charge of refrigerant and compressor lubricating oil,

and are ready for operation upon installation.

The base unit operates on nominal 380/460 volt, 3-phase, 50/60 hertz (Hz) power. An optional autotransformer

may be fitted to allow operation on nominal 190/230, 3-phase, 50/60 Hz power. Control system power is provided

by a transformer which steps the supply power down to 18 and 24 volts, single phase.

The controller is a Carrier Transicold Micro-Link 5 microprocessor. The controller operates automatically to select

cooling, holding or heating as required to maintain the desired set point temperature within very close limits. The

unit may also be equipped with an electronic temperature recorder. The controller has a keypad and display for

viewing or changing operating parameters. The display is also equipped with lights to indicate various modes of

operation.

2.2 Refrigerant

PrimeLINE models 69NT40-571-000 to 099 and PrimeLINE ONE™ models 69NT40-575-000 to 099 are units

designed to only be charged with R-134a refrigerant.

PrimeLINE models 69NT40-571-100 to 199

and PrimeLINE ONE™ models

69NT40-575-100 to 199 are R-513A-

ready units. They are supplied with a complete charge of R-134a refrigerant. But, they are capable of being field

converted to R-513A refrigerant at a later date as requested by the unit owner. R-513A is an azeotrope blend

containing R-1234yf and R-134a. All information in this manual pertaining to R-513A is only applicable to 571-100

to 199

units or 575-100 to 199 units that have either been converted or are being converted to R-513A.

To convert a R-513A-ready unit to R-513A refrigerant, refer to procedure in Service

.

2.3 Configuration Identification

Unit identification information is provided on a plate located on the back wall of the condenser section. The plate

provides the unit model number, the unit serial number and the unit parts identification number (PID). The model

number identifies the overall unit configuration, while the PID number provides information on specific optional

equipment, factory provisioned to allow for field installation of optional equipment and differences in detailed parts.

2.4 Feature Descriptions

2.4.1

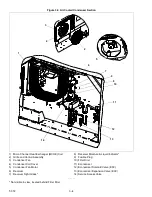

Control Box

Units are equipped with an aluminum control box, and may be fitted with a lockable door.

2.4.2

Temperature Readout

The unit is fitted with suction and discharge refrigerant temperature sensors. The sensor readings may be viewed

on the controller display.

2.4.3

Pressure Readout

The unit is fitted with evaporator, suction, and discharge pressure transducers. The transducer readings may be

viewed on the controller display.