T-372

5–2

PROCEDURE:

1. Make sure the Start-Stop switch (ST), located on the control panel, is in “0” position (Off).

2. Make sure circuit breaker CB-1, located in the control box, and CB-2, located on the transformer, are both in

“0” position (Off).

3. Plug in and lock the 460 VAC power plug at the receptacle on the transformer.

4. Plug the 230 VAC (black) cable into a de-energized 190/230 VAC, 3-phase power source and energize the

power source.

5. Set circuit breakers CB-1 and CB-2 to “I” position (On).

6. Close and secure the control box door.

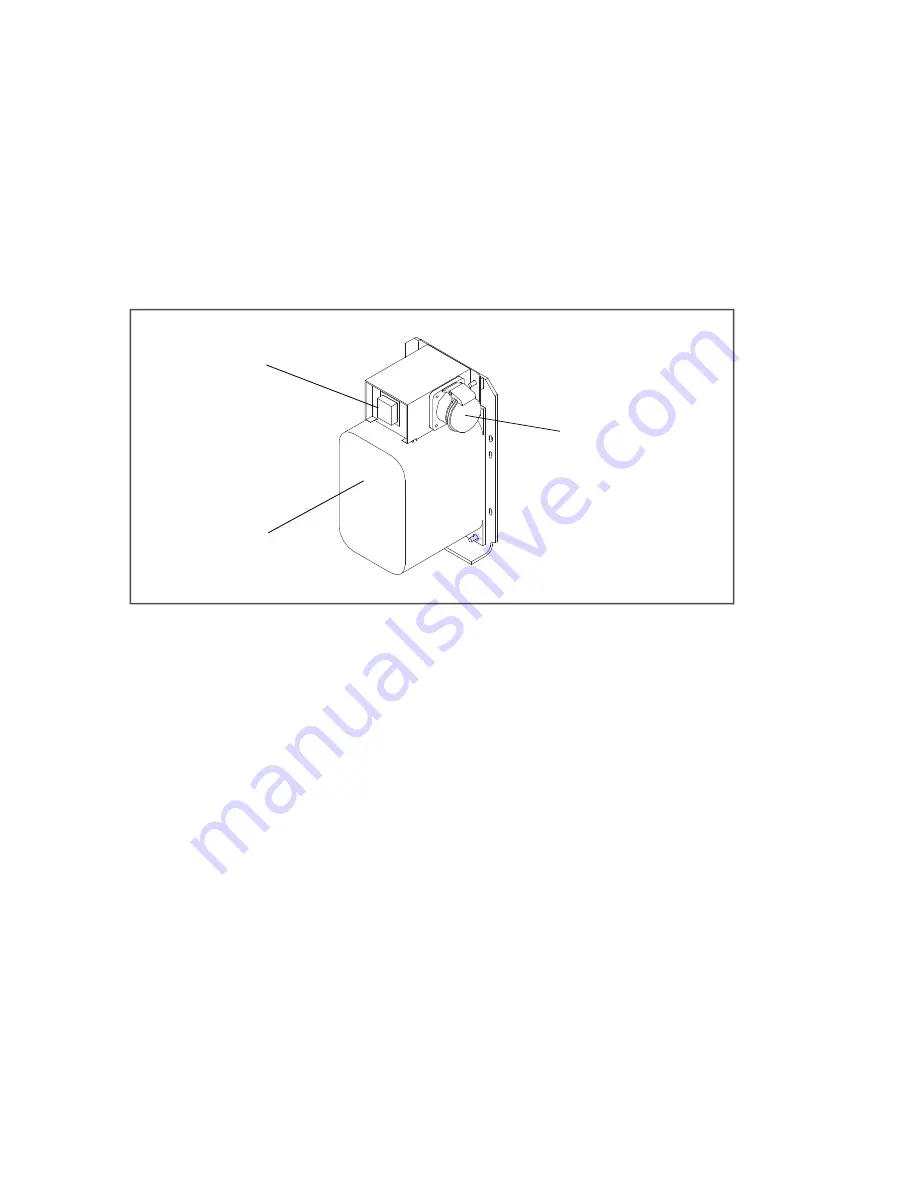

Figure 5.1 Autotransformer

1) Circuit Breaker (CB-2) 230-Volt

2) 460 VAC Power Receptacle

3) Dual Voltage Modular

Autotransformer

- - - - -

5.3 Adjust Fresh Air Makeup Vent

The purpose of the fresh air makeup vent is to provide ventilation for commodities that require fresh air circulation.

The vent

must be closed

when transporting frozen foods.

Air exchange depends on static pressure differential, which will vary depending on the container and how the con

-

tainer is loaded.

Units may be equipped with a vent position sensor (VPS). The VPS determines the position of the upper fresh air

vent (as equipped) and sends data to the controller display.

5.3.1

Upper Fresh Air Makeup Vent

Two slots and a stop are designed into the Upper Fresh Air disc for air flow adjustments. The first slot allows for a 0

to 30% air flow; the second slot allows for a 30 to 100% air flow.

To adjust the percentage of air flow, loosen the wing nut and rotate the disc until the desired percentage of air flow

matches with the arrow. Tighten the wing nut.

To clear the gap between the slots, loosen the wing nut until the disc clears the stop.

See

for air exchange values for an empty container. Higher values can be expected for a fully loaded

container.

1

3

2