8–5

62-11785

8.5

REFRIGERANT SYSTEM SERVICE

Service of refrigerant system equipment, refrigerant charge, leak checking and evacuation.

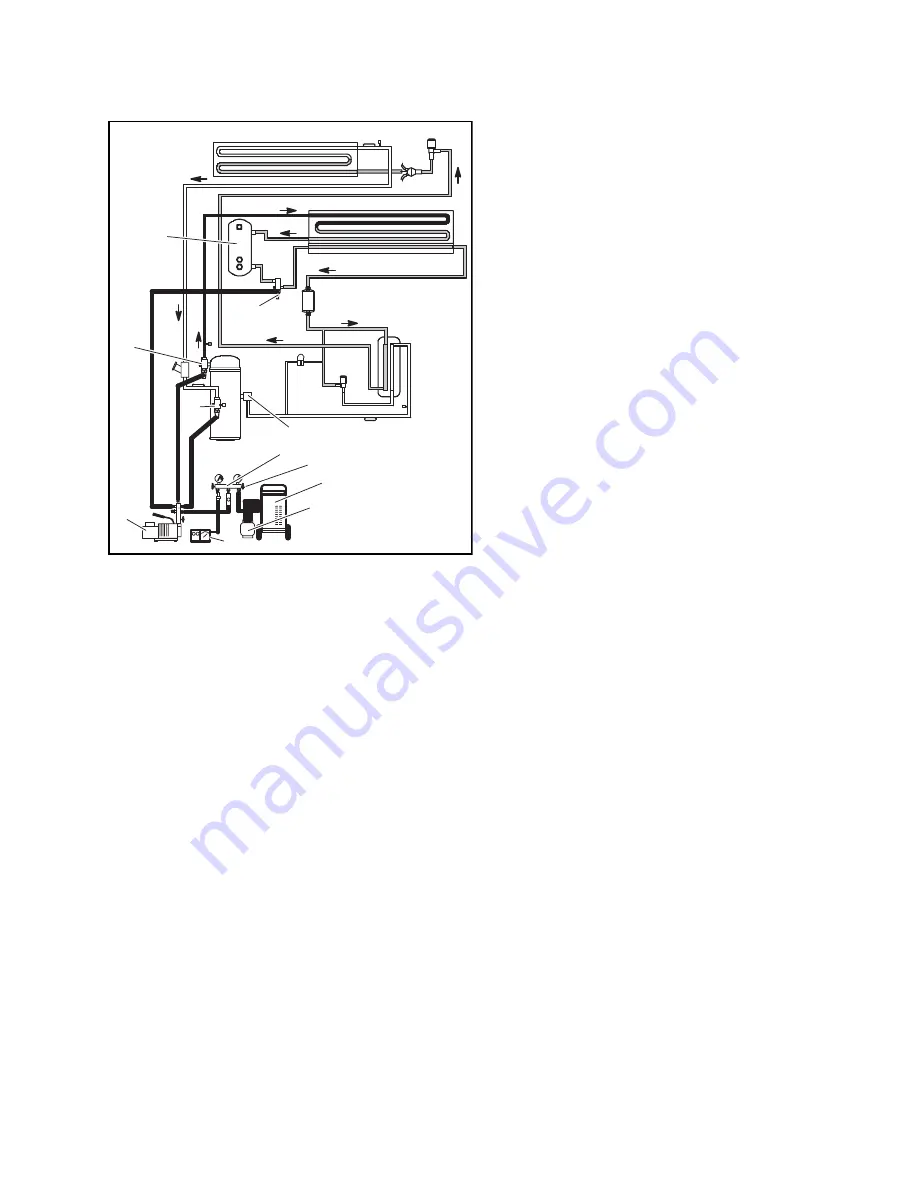

Figure 8.4 Refrigerant System Service

1.

Vacuum Pump

2.

Vacuum Indicator

3.

Refrigerant Cylinder

4.

Refrigerant Recovery Unit

5.

Valve

6.

Manifold Gauge Set

7.

Economizer Connection

8.

Suction Service Valve

9.

Liquid Injection Valve

10. Economizer Expansion Valve

11. Economizer

12. Evaporator

13. Evaporator Expansion Valve

14. Compressor Suction Modulation Valve (CSMV)

15. Subcooler

16. Condenser

17. Receiver

18. Liquid Line Service Valve

19. Discharge Service Valve

20. Compressor

8.5.1

Refrigerant System Service Connections

To service the refrigerant system, service equipment is connected at the compressor discharge service valve,

compressor suction service valve, and/or the liquid line service valve.

When connecting to a valve, backseat the valve (turn counterclockwise) to close off gauge connection and attach

service line to the valve. Open valve 1/4 to 1/2 turn (clockwise) and purge the service line. See

for an

example of a full service connection setup.

NOTE

To avoid damage to the earth’s ozone layer, use a refrigerant recovery system whenever removing

refrigerant from a refrigeration system. When working with refrigerants you must comply with all local

government environmental laws, U.S.A. EPA section 608.

8.5.2

Servicing The Refrigerant Charge

Servicing of the refrigerant charge includes: checking charge level, checking for noncondensibles, removing the

charge, pumping down the low side, pumping down the compressor, adjusting the charge level and adding a

complete charge. Procedures for charge service are provided in the following sub paragraphs.

a. Checking Charge Level

Check refrigerant charge before adding any refrigerant to the system. Only add refrigerant if charge is low. If charge is

low, leak checking must be performed (refer to

) and all leaks repaired before adding refrigerant.

1. Install a manifold gauge set to allow reading of discharge pressure. See

.

2. Start unit in Continuous Operation. Adjust setpoint so that unit is and operating in economized mode. Use

Technician Mode to verify that the ECXV is open.

3. Run approximately ten minutes - until the refrigeration system is warmed up and the refrigerated compartment

temperature is approaching setpoint.

4. Partially block off air flow to condenser coil so discharge pressure rises to 230 psig (15.7 bar).

5. Check the receiver sight glasses to determine charge. The system is correctly charged when the lower sight

glass is not empty and the upper sight glass is not full.

6. If the system appears to be overcharged or under charged, adjust charge. Refer to following step f.

Summary of Contents for VECTOR 8100

Page 2: ......

Page 4: ......

Page 12: ...62 11785 viii ...

Page 16: ...62 11640 12 ...

Page 18: ...62 11785 ...

Page 24: ...62 11785 1 6 1 3 SAFETY DECALS ...

Page 25: ...1 7 62 11785 ...

Page 26: ...62 11785 1 8 ...

Page 27: ...1 9 62 11785 ...

Page 28: ...62 11785 1 10 ...

Page 30: ...62 11785 ...

Page 50: ...62 11785 ...

Page 82: ...62 11785 ...

Page 96: ...62 11785 4 14 ...

Page 98: ...62 11785 ...

Page 129: ...5 31 62 11785 ...

Page 130: ...62 11785 5 32 ...

Page 134: ...62 11785 6 4 ...

Page 138: ...62 11785 ...

Page 230: ...62 11785 ...

Page 271: ...8 41 62 11785 ...

Page 272: ...62 11785 8 42 ...

Page 274: ...62 11785 ...

Page 286: ......

Page 287: ......

Page 288: ...62 11785 10 8 ...

Page 292: ......

Page 293: ......