8–21

62-11785

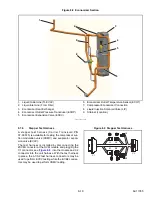

c. Diagnostics - Valve

NOTE

If the valve failed pretest and passed the preceding diagnostic testing, this is an indication the valve

mechanism is damaged and the internal motor/piston assembly is to be replaced.

1. To test the valve internal mechanism, install a manifold gauge set on the suction service valve and a stepper

motor drive tester.

2. Start the unit, set the step rate to 150 steps per second and close the valve while watching the suction pressure.

Within one minute the suction pressure should begin to fall. Place the START/RUN-OFF switch in the OFF

position before the reading enters a vacuum.

3. If the suction pressure does not change, this is an indication the valve is stuck and the internal motor/piston

assembly is to be replaced.

d. Replacing The Internal Motor/Piston Assembly

1. Pump down the low side. Refer to

.

2. Remove internal motor/piston assembly and replace with a new assembly and gaskets. The motor/piston

assembly should be set to 100% open when received from the warehouse. This is to ensure the valve seal is

not damaged when it is installed. Ensure the valve is fully open by using the stepper motor tester to manually

open the valve to 100% before it is installed. Ensure the gasket is installed in the body groove, and torque the

body screws 80 to 97 inch/lbs (9 to 11 Nm).

3. Leak check, evacuate & dehydrate, and charge system as required. Refer to

&

e. Emergency Repair Procedures

In the event that the CSMV system has a failure and replacement components are not readily available, an

emergency, a

LIMP-HOME

procedure can be done as follows:

1. Install a manifold gauge set.

2. Pump down the low side. Refer to

.

3. Remove the internal motor/piston assembly.

4. Loosen the Allen screw and remove the piston and screw.

5. Install the motor/piston assembly (without the piston). Torque the nut 35 to 40 ft/lb (47.5 to 54.2 Nm) or body

screws 80 to 97 inch/lbs (9 to 11 Nm) as applicable.

6. Leak check, evacuate & dehydrate, and charge system as required. Refer to

&

7. Start the unit.

8. Adjust the suction service valve so that the approximate temperature is maintained. For perishable loads, it

is recommended that the adjustment be made so that available capacity is slightly larger than the load, the

unit will cycle OFF and ON.

9. Once repair parts become available, repair as required.

Summary of Contents for VECTOR 8100

Page 2: ......

Page 4: ......

Page 12: ...62 11785 viii ...

Page 16: ...62 11640 12 ...

Page 18: ...62 11785 ...

Page 24: ...62 11785 1 6 1 3 SAFETY DECALS ...

Page 25: ...1 7 62 11785 ...

Page 26: ...62 11785 1 8 ...

Page 27: ...1 9 62 11785 ...

Page 28: ...62 11785 1 10 ...

Page 30: ...62 11785 ...

Page 50: ...62 11785 ...

Page 82: ...62 11785 ...

Page 96: ...62 11785 4 14 ...

Page 98: ...62 11785 ...

Page 129: ...5 31 62 11785 ...

Page 130: ...62 11785 5 32 ...

Page 134: ...62 11785 6 4 ...

Page 138: ...62 11785 ...

Page 230: ...62 11785 ...

Page 271: ...8 41 62 11785 ...

Page 272: ...62 11785 8 42 ...

Page 274: ...62 11785 ...

Page 286: ......

Page 287: ......

Page 288: ...62 11785 10 8 ...

Page 292: ......

Page 293: ......