8–23

62-11785

b. Diagnostics - Stepper Motor

The valve stepper motor may be tested using a stepper motor drive tester or ohmmeter.

1. To test with a stepper motor drive tester (Carrier

Transicold P/N 07-00375-00SV), connect the 5

pin test cable to the valve connector (see

), and the cable wires to the tester in accor-

dance with wire and terminal color. (if a 5 pin

tester cable is required, order Carrier Transicold

P/N 07-00375-11.)

2. 2. Set the step rate to 50 steps per second and

either open or close the valve. Each red LED

should light sequentially until all four are

illuminated. Any LED failing to illuminate indicates

an open on that leg and a need to replace the

drive.

3. 3. To test with an ohmmeter, check the winding

resistance between connector pin A & E, B & E, C

& E and then between D & E. In normal ambient,

the resistance between the pins should be 46

ohms. If an infinite or zero reading is observed,

the piston and drive motor assembly is to be

replaced.

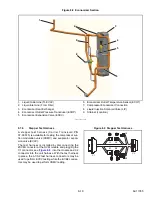

Figure 8.13 Evaporator Expansion Valve

c. Diagnostics - Valve

If the valve failed Pre-trip and passed the preceding diagnostic testing, this is an indication that the valve internal

mechanism is damaged and the piston and motor assembly is to be replaced.

Test the EVXV valve internal mechanism:

1. Install a manifold gauge set on the suction service valve and a stepper motor drive tester. Refer to

NOTICE

The scroll compressor achieves low suction pressure very quickly. Do not use the compressor

to evacuate the system below 0 psig. Never operate the compressor with the suction or

discharge service valves closed (frontseated). Internal damage will result from operating the

compressor in a deep vacuum.

2. Start the unit, set the step rate to 150 steps per second, open and close the valve while watching the suction

pressure. Within one minute the suction pressure should begin to fall.

3. If the suction pressure does not change, this is an indication the valve is stuck and the piston and drive motor

assembly is to be replaced.

Test the ECXV valve internal mechanism:

1. To test the ECXV, install a stepper motor drive tester to the valve, refer to

2. Use the stepper motor drive tester to close the ECXV completely, and run the unit for 5 minutes.

3. Check for a temperature change through the valve. If there is a temperature change, it indicates that the ECXV

is stuck open and needs to be replaced. If there is not a temperature change, record the CDT and AC current

from Unit Data.

4. Use the stepper motor drive tester to open the ECXV, and run the unit for 5 minutes.

5. Check for a temperature change through the valve, if there is a temperature change, it indicates that the ECXV

opened correctly.

6. From Unit Data, make sure the CDT temperature reading went down, and that the AC current draw went up.

A

B

B

A

PIN A (ORANGE)

PIN B (RED)

PIN C (YELLOW)

PIN E (GRAY)

PIN D (BLACK)

COMMON

(+12VDC)

Summary of Contents for VECTOR 8100

Page 2: ......

Page 4: ......

Page 12: ...62 11785 viii ...

Page 16: ...62 11640 12 ...

Page 18: ...62 11785 ...

Page 24: ...62 11785 1 6 1 3 SAFETY DECALS ...

Page 25: ...1 7 62 11785 ...

Page 26: ...62 11785 1 8 ...

Page 27: ...1 9 62 11785 ...

Page 28: ...62 11785 1 10 ...

Page 30: ...62 11785 ...

Page 50: ...62 11785 ...

Page 82: ...62 11785 ...

Page 96: ...62 11785 4 14 ...

Page 98: ...62 11785 ...

Page 129: ...5 31 62 11785 ...

Page 130: ...62 11785 5 32 ...

Page 134: ...62 11785 6 4 ...

Page 138: ...62 11785 ...

Page 230: ...62 11785 ...

Page 271: ...8 41 62 11785 ...

Page 272: ...62 11785 8 42 ...

Page 274: ...62 11785 ...

Page 286: ......

Page 287: ......

Page 288: ...62 11785 10 8 ...

Page 292: ......

Page 293: ......