62-11785

8–32

8.8.7

Light Bar

The light bar may be tested using a 12 VDC source.

1. Ensure unit will not start automatically by

placing the START/RUN-OFF switch in the OFF

position and removing the negative battery

cable. Disconnect the high voltage source and

lockout/tagout the receptacle.

2. Connect the ground (-) from the power source to

pin G on the light bar side of the connector.

3. The green LED’s will illuminate when the 12

VDC side (+) of the power source is connected

to pin B.

4. With the connection as in the preceding steps (+

on pin B, and - on pin G), the amber LED’s will

illuminate when the power (+) from the power

source is also connected to pin H.

5. Reinstall the negative battery cable, start unit

and run Pretrip to check operation.

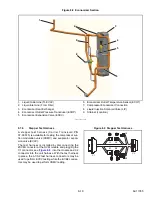

Figure 8.21 Light Bar Connections

8.8.8

Overload Ground Fault (OGF)

Operation

The OGF is designed to detect current overload and

fault to ground in the AC voltage circuits. The function

of the OGF is to shut down the power supply when

current is over 40 amp for 2 seconds, or leakage to

ground is more than 150mA.

Power, from HVB1K, energizes the OGF at terminal

+12 V. The module is grounded by the microprocessor

at the OV terminal through SP50.

This power also flows through the OGF normally

closed contacts and the S+ terminal through SP63 to

2CCB. If an overload or excessive leakage to ground

condition exists, the OGF contacts open to de-energize

and stop the flow of power to CCB1. Loss of power at

CCB1 activates alarm

.

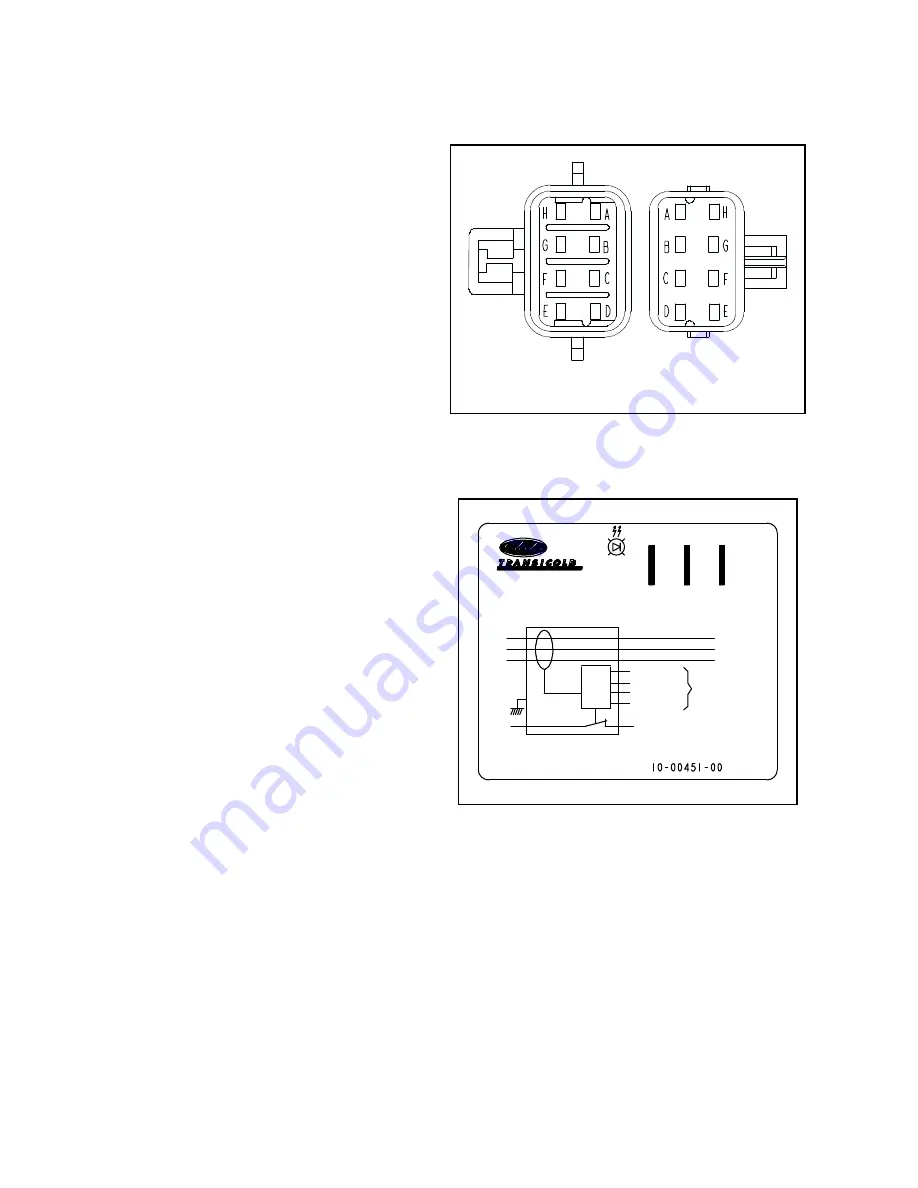

Figure 8.22 Overload Ground Fault Connections

OGF Checkout Procedure

1. Check the FAULT LED on the module. If the LED is illuminated the module has activated and 12 VDC power

supply is correct. Perform a megohm test (refer to

) to determine if a fault to ground exists.

This test will also help determine if an excessive current condition exists due to leakage to ground. Repair

wiring or components as required.

is present and the fault LED (on the module) is not illuminated,

it means that the module has detected an overcurrent. Verify the current readout on the unit data.

If current readings are not reading correctly, the current sensor may be at fault. Go to step 5 & 6 to check the

current sensor.

3. If a problem with the module is suspected, check for 12VDC power to the module at the +12V terminal and

ground at the OV terminal. Correct wiring as required. Reset module by placing the Main Power switch in the

OFF position and then back in the desired position. Check for 12 VDC at the S+ terminal. If LED is off and the

module normally closed connection is open, replace module.

4. If module is OK, check for 12 VDC at SP63.

A

H

E

F

G

D

C

B

LIGHT BAR

SIDE

CONTROL BOX

SIDE

A

H

E

F

G

D

C

B

GROUND

FAULT

S+

+12V

OV

L1

L2

L3

BLUE

BROWN

ORANGE

BLACK

TO CURRENT

SENSORS

S+

OV

+12V

Summary of Contents for VECTOR 8100

Page 2: ......

Page 4: ......

Page 12: ...62 11785 viii ...

Page 16: ...62 11640 12 ...

Page 18: ...62 11785 ...

Page 24: ...62 11785 1 6 1 3 SAFETY DECALS ...

Page 25: ...1 7 62 11785 ...

Page 26: ...62 11785 1 8 ...

Page 27: ...1 9 62 11785 ...

Page 28: ...62 11785 1 10 ...

Page 30: ...62 11785 ...

Page 50: ...62 11785 ...

Page 82: ...62 11785 ...

Page 96: ...62 11785 4 14 ...

Page 98: ...62 11785 ...

Page 129: ...5 31 62 11785 ...

Page 130: ...62 11785 5 32 ...

Page 134: ...62 11785 6 4 ...

Page 138: ...62 11785 ...

Page 230: ...62 11785 ...

Page 271: ...8 41 62 11785 ...

Page 272: ...62 11785 8 42 ...

Page 274: ...62 11785 ...

Page 286: ......

Page 287: ......

Page 288: ...62 11785 10 8 ...

Page 292: ......

Page 293: ......