8–33

62-11785

5. Check wiring between CT and pins 1CCB10, 1CCB12, 1CCB31, and 1CCB34 as required.

6. If a problem with the current sensors is suspected, check sensor output. Current sensor inputs to the module are

rated at 16.7mV per Amp. For every Amp that is read at the wires coming from the PSCON T1, T2 and T3

terminals with an amp meter, there should be a corresponding voltage reading on the blue, brown & orange

wires to the black wire. For example: 20Amps = 0.33VAC.

7. Sensor resistance should also be checked, all wires must be disconnected. Check from Black to each phase:

Black to Orange - 22 ohms

Black to Blue - 22 ohms

Black to Brown - 22 ohms

If any resistance values are not within proper range (22 ohms) it indicates a defective sensor.

8.8.9

Evaporator Heaters

NOTE

A good preliminary test of the heaters is to run a Pretrip and check for heater alarms.

1. Ensure the unit will not start automatically by disabling any two way communication and placing the START/

RUN-OFF switch in the OFF position. Disconnect the high voltage source and lockout/tagout the receptacle.

2. Remove the lower back panel or coil cover as applicable.

3. To determine which heater assembly needs to be replaced, disconnect the suspect heater assembly and check

pin to pin resistance. For heater resistance refer to

4. Remove the heater mounting brackets.

5. Remove and replace faulty heater. If removing a drain pan heater, carefully remove heater from the clips on the

drain pan.

6. When reinstalling brackets torque to 6 to 7 ft/lbs (8.1 to 9.5 Nm). Rods should move freely from side to side when

installed.

7. Route and secure electrical cables. Route along the lower side of the heat exchanger at the 5 o’clock position

(on the side closest to the evaporator coil). Ensure that all wires are clear of heaters.

8. Reinstall the negative battery cable, start unit and run Pretrip to check operation.

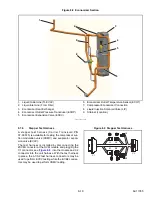

8.8.10

Evaporator Blower & Motor

NOTE

Blower motor bearings are factory sealed and do not require additional grease.

1. Ensure the unit will not start automatically by disabling any two way communication and placing the START/

RUN-OFF switch in the OFF position. Disconnect the high voltage source and lockout/tagout the receptacle.

2. From inside of trailer, remove back panel and grille (see

).

3. Disconnect the motor electrical connector.

4. Remove the supply air sensor and then remove the nozzle.

5. Loosen the four bolts on the underside of the support bracket that fasten the two mounting brackets.

6. Slide the blower assembly off the support bracket and out of the unit.

7. To remove the fan, loosen the nut holding the blade to the motor shaft using impact gun.

Summary of Contents for VECTOR 8100

Page 2: ......

Page 4: ......

Page 12: ...62 11785 viii ...

Page 16: ...62 11640 12 ...

Page 18: ...62 11785 ...

Page 24: ...62 11785 1 6 1 3 SAFETY DECALS ...

Page 25: ...1 7 62 11785 ...

Page 26: ...62 11785 1 8 ...

Page 27: ...1 9 62 11785 ...

Page 28: ...62 11785 1 10 ...

Page 30: ...62 11785 ...

Page 50: ...62 11785 ...

Page 82: ...62 11785 ...

Page 96: ...62 11785 4 14 ...

Page 98: ...62 11785 ...

Page 129: ...5 31 62 11785 ...

Page 130: ...62 11785 5 32 ...

Page 134: ...62 11785 6 4 ...

Page 138: ...62 11785 ...

Page 230: ...62 11785 ...

Page 271: ...8 41 62 11785 ...

Page 272: ...62 11785 8 42 ...

Page 274: ...62 11785 ...

Page 286: ......

Page 287: ......

Page 288: ...62 11785 10 8 ...

Page 292: ......

Page 293: ......