62-11785

8–36

8.8.12

Battery Charger (BTYC)

NOTE

A battery of known good condition must be connected to the charger before doing the following test.

The charger operates only when the input voltage is between 275 VAC and 640VAC. If either limit is

exceeded it will not function. It should resume charging when the input voltage rises above 275-293

VAC or falls below 620-630 VAC.

1. Run the unit with the battery charger connected to the battery as usual.

2. Using a clamp-on ammeter, take a reading of the amperage on both output wires of the battery charger. If

charging current is between 3 and 40 amps, for 40 amp (three phase) chargers, the battery charger is

functioning correctly.

3. If charging Amps = 0, check the AC input voltage to the charger. The AC input voltage range should be between

350 and 600 VAC.

4. If there is no AC voltage, ensure the unit will not start automatically by disabling any two way communication and

placing the START/RUN-OFF switch in the OFF position. Disconnect the high voltage source and lockout/tagout

the receptacle.

5. Check battery charger fuses and inspect fuse holder wire connections. Inspect plugs, pins and wires at charger

connections.

6. If input voltage, wiring connections and the fuses are good, replace the battery charger.

8.8.13

Compressor Discharge Temperature Sensor

Values for testing the sensor, in accordance with standard procedures, are provided in

. To replace the

compressor discharge temperature sensor (see

) do the following:

1. Ensure the unit will not start automatically by placing the START/RUN-OFF switch in the OFF position. Dis-

connect the high voltage source and lockout/tagout the receptacle.

2. Remove the existing sensor. Clean all silicone sealer and dielectric compound from the sensor well. Ensure well

is clean and dry. Top of compressor, where the sensor seals, must also be clean and dry.

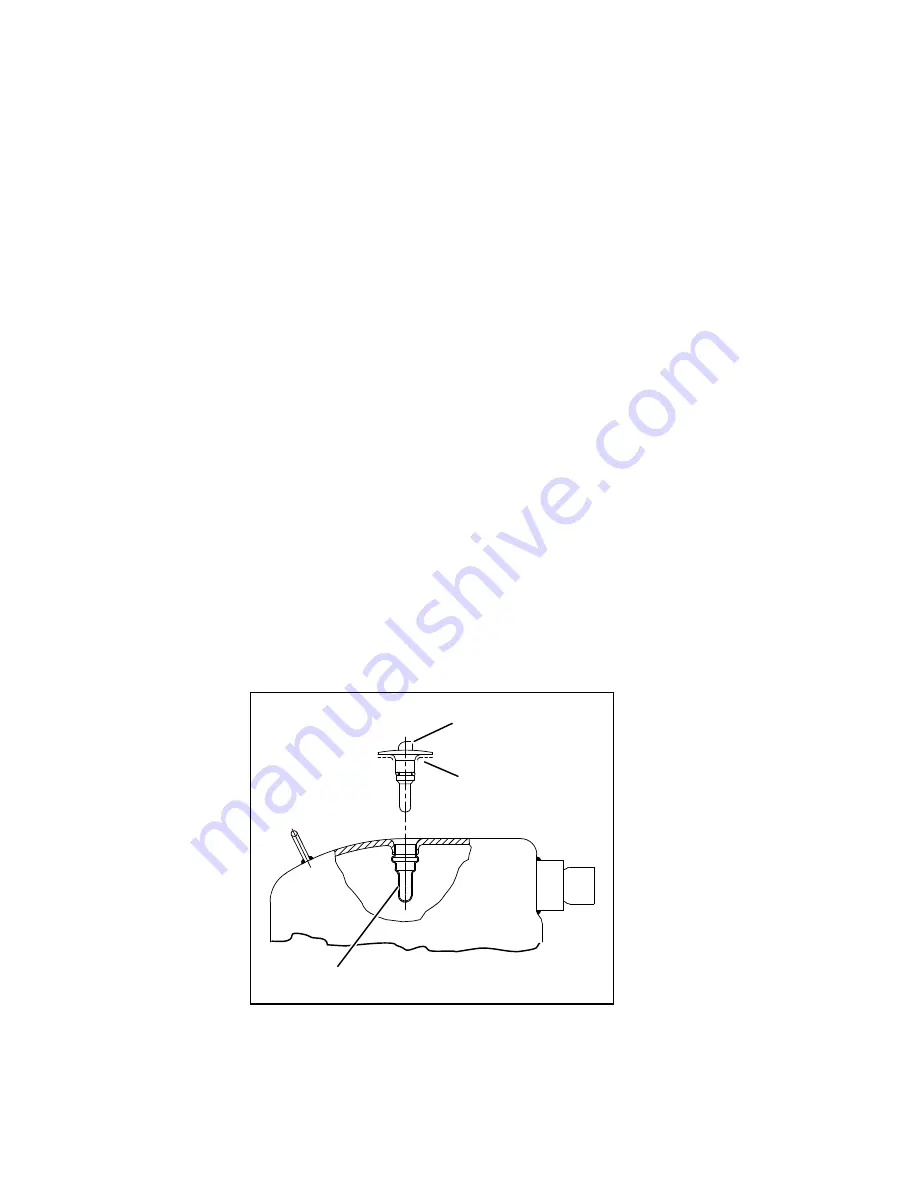

Figure 8.25 Compressor Discharge Temperature Sensor

3. Using the syringe supplied with the replacement sensor, squeeze all of the dielectric compound into the sensor

well.

4. Place a bead of the silicone sealer supplied with the replacement sensor around the sensor sealing ring. Insert

sensor into the well with the leads parallel to the suction fitting.

5. Reconnect sensor connector and run a Pretrip to test.

SENSOR WELL

SENSOR

SILICONE BEAD

Summary of Contents for VECTOR 8100

Page 2: ......

Page 4: ......

Page 12: ...62 11785 viii ...

Page 16: ...62 11640 12 ...

Page 18: ...62 11785 ...

Page 24: ...62 11785 1 6 1 3 SAFETY DECALS ...

Page 25: ...1 7 62 11785 ...

Page 26: ...62 11785 1 8 ...

Page 27: ...1 9 62 11785 ...

Page 28: ...62 11785 1 10 ...

Page 30: ...62 11785 ...

Page 50: ...62 11785 ...

Page 82: ...62 11785 ...

Page 96: ...62 11785 4 14 ...

Page 98: ...62 11785 ...

Page 129: ...5 31 62 11785 ...

Page 130: ...62 11785 5 32 ...

Page 134: ...62 11785 6 4 ...

Page 138: ...62 11785 ...

Page 230: ...62 11785 ...

Page 271: ...8 41 62 11785 ...

Page 272: ...62 11785 8 42 ...

Page 274: ...62 11785 ...

Page 286: ......

Page 287: ......

Page 288: ...62 11785 10 8 ...

Page 292: ......

Page 293: ......