62-11785

8–18

8.7.3

Filter-Drier

a. Check Filter-Drier

The unit must be running in cool for this test. Check for a restricted or plugged filter-drier by feeling the liquid line

inlet and outlet connections of the drier cartridge.

If the outlet side feels cooler than the inlet side, then the filter-drier should be replaced.

b. Replace Filter-Drier

1. Pump down the low side. Refer to

2. Remove bracket, loosen the inlet connection to relieve any remaining pressure then remove drier.

3. Procure new O-rings. Lubricate the O-rings, back side of sleeves and coupling nuts. Using a backup wrench at

each connection torque 30 to 38 ft/lbs (40.7 to 51.5 Nm).

4. Leak check, evacuate & dehydrate, and charge system as required. Refer to

&

8.7.4

Replacing Receiver Sight Glass Or Fusible Plug

1. Remove the refrigerant charge. Refer to

.

2. Loosen the sight glass or fusible plug to relieve any remaining pressure. Remove and discard glass or plug.

3. Using new o-ring, install component. Torque the sight glass to 15 to 25 ft/lbs (20.3 to 33.9 Nm). Torque the fusible

plug to 48 to 96 inch/lbs (5.4 to 10.8 Nm).

4. Leak check, evacuate & dehydrate, and charge system as required. Refer to

&

8.7.5

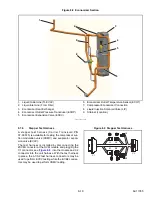

Economizer Heat Exchanger

1. Pump down the low side. Refer to

.

2. Ensure the unit will not start automatically by placing the START/RUN-OFF switch in the OFF position.

Disconnect the high voltage source and lockout/tagout the receptacle.

3. Remove insulation, brackets and clamps from economizer line assemblies as required (refer to

4. Remove the economizer expansion valve and liquid injection solenoid valve coils.

5. Remove the economizer outlet pressure transducer and economizer outlet temperature sensor.

6. Unbraze four lines at the economizer connections.

7. Note orientation of economizer (mounted with connection markings upside-down). Remove economizer heat

exchanger, bolt replacement economizer heat exchanger in place and rebraze lines by reversing the previous

steps.

8. Leak check, evacuate the unit and charge.

9. Reinstall the economizer outlet pressure transducer, economizer outlet temperature sensor, valve coils and

insulation.

10. Place unit back in service and check operation.

Summary of Contents for VECTOR 8100

Page 2: ......

Page 4: ......

Page 12: ...62 11785 viii ...

Page 16: ...62 11640 12 ...

Page 18: ...62 11785 ...

Page 24: ...62 11785 1 6 1 3 SAFETY DECALS ...

Page 25: ...1 7 62 11785 ...

Page 26: ...62 11785 1 8 ...

Page 27: ...1 9 62 11785 ...

Page 28: ...62 11785 1 10 ...

Page 30: ...62 11785 ...

Page 50: ...62 11785 ...

Page 82: ...62 11785 ...

Page 96: ...62 11785 4 14 ...

Page 98: ...62 11785 ...

Page 129: ...5 31 62 11785 ...

Page 130: ...62 11785 5 32 ...

Page 134: ...62 11785 6 4 ...

Page 138: ...62 11785 ...

Page 230: ...62 11785 ...

Page 271: ...8 41 62 11785 ...

Page 272: ...62 11785 8 42 ...

Page 274: ...62 11785 ...

Page 286: ......

Page 287: ......

Page 288: ...62 11785 10 8 ...

Page 292: ......

Page 293: ......