1–5

62-11640

NOTICE

Ensure that the clock you are using is

accurate. Also, some customers are

located in different time zones from the

repair location. If you know the owners

desired location time, enter that time. If

you don’t, enter the current time at your

location.

NOTICE

DO NOT leave the air intake circuit ener-

gized for the full 5 minutes if full amper-

age is shown, as the intake air heater

element life will be greatly shortened.

NOTICE

Unit uses R404A and POE oil. The use of

inert gas brazing procedures is manda-

tory for all Carrier Transicold refrigera-

tion units; otherwise compressor failure

will occur. For more information Refer to

Technical Procedure 98-50553-00 Inert

Gas Brazing.

NOTICE

Running the engine for an extended

period of time with the manual plunger up

can cause a priming pump failure.

NOTICE

Torque fuel level sensor mounting

screws to 15 to 18 inch/lbs (1.7 to 2.0

Nm). DO NOT over tighten, as little as 20

inch/pounds (2.3 Nm) will damage the

sensor.

NOTICE

When changing oil filters, the new filters

should be primed (partially filled) with

clean oil if possible. If the filters are not

primed, the engine may operate for a

period with no oil supplied to the bearings.

NOTICE

NEVER POUR COLD WATER INTO A HOT

ENGINE, however hot water can always

be added to a cold engine.

NOTICE

Use only ethylene glycol anti-freeze (with

inhibitors) in system as glycol by itself

will damage the cooling system. Always

add pre-mixed 50/50 anti-freeze and water

to radiator / engine. Never exceed more

than a 60% concentration of anti-freeze.

Use a low silicate anti-freeze meeting GM

specifications GM 6038M for standard life

coolant or use Texaco Havoline extended

life coolant or any other extended life

coolant which is Dexcool approved and

has 5/150 (5 years / 150,000 miles) on the

label.

NOTICE

The scroll compressor achieves low suc-

tion pressure very quickly. Do not use the

compressor to evacuate the system

below 0 psig. Never operate the compres-

sor with the suction or discharge service

valves closed (frontseated). Internal dam-

age will result from operating the com-

pressor in a deep vacuum.

NOTICE

When a module is replaced, software

should be upgraded before switching the

unit on. This will ensure software com-

patibility of all modules.

NOTICE

Do not vapor charge R404A. Only liquid

charging through the liquid line service

valve is acceptable.

NOTICE

Do not bend the copper tubing on the

condenser coil when installing the new

condenser. Bend the unit tubing if tubes

do not align correctly.

NOTICE

Under no circumstances should anyone

attempt to repair sealed module internal

components. Should a problem develop

with these components, contact your

nearest Carrier Transicold dealer for

replacement.

Change 09/14

Summary of Contents for Vector 8500

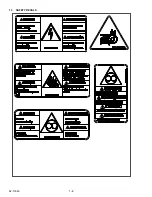

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

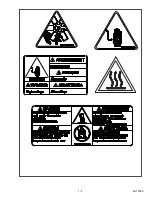

Page 24: ...1 7 62 11640 62 03958 ...

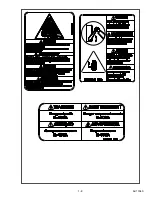

Page 25: ...62 11640 1 8 ...

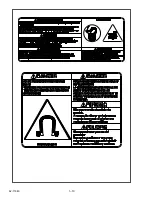

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......