8–11

62-11640

8.5.9

Engine Oil and Oil Filter

a. To Check The Engine Oil Level:

1. Warm up the engine and then stop it by placing

the STOP/RUN-OFF switch in the OFF position.

Disconnect the high voltage source and lockout/

tagout the receptacle.

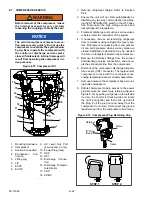

2. Unscrew the cap/dipstick see

the dipstick clean and insert the cap into the oil

fill tube without threading into tube.

3. Remove the dipstick again and check oil level.

DO NOT add oil if the level is in the “safe” range.

If needed, add oil as indicated by markings on

dipstick until level is in the “safe” range.

4. After checking or adding oil as necessary,

ensure cap is threaded back onto oil fill tube.

Figure 8.11 Engine Oil Level

b. To Change Engine Oil:

1. Warm up the engine and then stop it by placing

the STOP/RUN-OFF switch in the OFF position.

Ensure the unit will not start automatically by

disabling any two way communication. Discon-

nect the high voltage source and lockout/tagout

the receptacle.

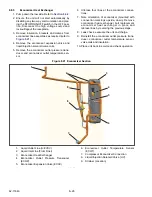

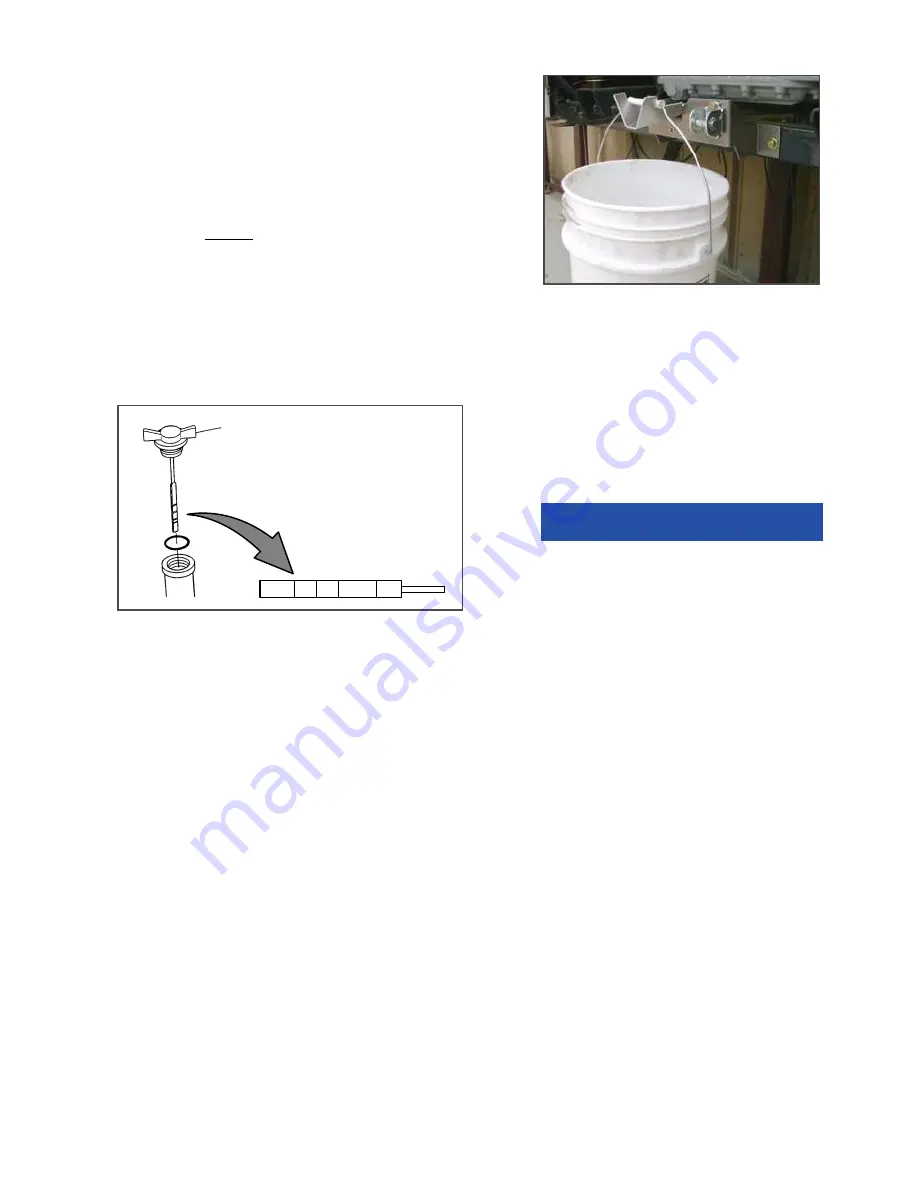

2. If available, install oil drain tool (CTD P/N 68-

15763-01). See

. The Oil Drain Tool

not only directs the oil over the door latch pin

bracket and bottom panel, on units so equipped,

but also holds a typical drain bucket in place

while the oil is draining from the engine.

3. Remove drain plug drain engine oil. Replace

plug and refill engine with oil. Continue with step

c. and change oil filter.

Figure 8.12 Oil Drain Tool

c. To Change Engine Oil Filter:

1. If not continuing from preceding step b., warm

up the engine and then stop it by placing the

STOP/ RUN-OFF switch in the OFF position.

Ensure the unit will not start automatically by

disabling any two way communication. Discon-

nect the high voltage source and lockout/tagout

the receptacle.

2. Remove oil filter. Ensure filter mounting is clean.

NOTICE

When changing oil filter, the new filter

should be primed (partially filled) with

clean oil if possible. If the filter is not

primed, the engine may operate for a

period with no oil supplied to the bearings.

3. Lightly oil gasket on new filter before installing.

Tighten 3/4 to 1 turn after the seal makes con-

tact.

4. Start unit and check for leaks.

8.5.10

Air Cleaner

The air cleaner should be inspected regularly for leaks.

A damaged air cleaner or hose can seriously affect the

performance and life of the engine. The air cleaner is

designed to effectively remove contaminants from the

air stream entering the engine. An excessive accumu-

lation of these contaminants in the air cleaner will

impair its operation; therefore, a service schedule must

be set up and followed.

Cap

Dipstick

QTS

1

2

SAFE

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......