62-11640

8–16

6. If gauge reading is not close to the calculated

saturation pressure in step 5, noncondensibles

or mixed refrigerants are present.

7. Remove refrigerant. Refer to following step c.

8. Leak check, evacuate & recharge the system.

c. Removing Charge

1. If the system is in operating condition, it will be

quicker to remove the charge by continuing with

step 2. If the system is not in operating condi-

tion, skip steps 2 through 5 and continue with

step 6.

2. Install a manifold gauge set to allow reading of

suction and discharge pressure.

WARNING

!

Only a refrigerant cylinder that has previ-

ously been used with R404A should be

connected to this refrigeration unit.

3. Connect a clean, evacuated refrigerant cylinder

to the liquid line service valve connection. Place

the cylinder on a weight scale so the refrigerant

going into the cylinder can be monitored.

4. Start the unit and run in high speed cool. Cover

the condenser to raise the discharge pressure to

as high as 375 psig (25.5 bar). Do not let the

discharge pressure exceed 400 psig (27.2 bar).

Open the refrigerant cylinder valve, and allow

the refrigerant to flow into the cylinder. The

amount of refrigerant going into the cylinder can

be monitored by watching the weight of the cyl-

inder.

5. Shutdown the unit when the suction pressure

drops to 2 psig (0.2 bar). There should be very

little refrigerant remaining in the system at this

point.

6. Place the unit in Service Mode (Refer to

). Ensure that the operator message

panel displays “RECOVER/LEAK CHK/EVAC

MODE” during the refrigerant removal proce-

dures. If the control system switches to charge

mode during the process, switch it back to the

“RECOVER/LEAK CHK/EVAC MODE”.

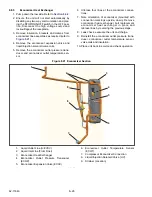

7. Connect a refrigerant recovery device and a

clean refrigerant recovery cylinder (or continue

to use the same cylinder used in step 3) as

shown in

ing refrigerant from the system.

8. Refer to instructions provided by the manufac-

turer of the refrigerant recovery unit.

9. After making necessary repairs, leak check,

evacuate and recharge the system.

d. Pumping Down The Low Side

Components on the low side of the refrigeration system

(the filter drier, EVXV, ECXV, evaporator coil, CSMV,

heat exchanger, suction line etc.) may be serviced or

replaced without having to completely remove the refrig-

erant charge from the system by pumping down the low

side, and temporarily storing the refrigerant in the con-

denser and receiver.

NOTICE

NOTICE The scroll compressor achieves

low suction pressure very quickly. Do not

use the compressor to evacuate the sys-

tem below 0 psig. Never operate the com-

pressor with the suction or discharge

service valves closed (frontseated). Inter-

nal damage will result from operating the

compressor in a deep vacuum.

1. Install a manifold gauge set to allow reading of

suction and discharge pressure.

2. Start the unit.

3. Frontseat the liquid line service valve.

4. Shutdown the unit when the suction pressure

drops to 2 psig (0.2 bar). There should be very

little refrigerant remaining in the low side of the

system at this point.

5. Monitor the gauges. The suction pressure

should not rise rapidly. If the suction pressure

continues to rise, the liquid line service valve

may not be properly closed. In this case, the low

side cannot be pumped down and the entire

refrigerant charge must be removed from the

system. (Refer to preceding step c.).

6. Ensure the unit will not start automatically by

disabling any two way communication and plac-

ing the STOP/RUN-OFF switch in the OFF posi-

tion. Disconnect the high voltage source and

lockout/tagout the receptacle.

7. Frontseat (close by turning clockwise) the dis-

charge service valve and the refrigerant will be

trapped between the compressor discharge ser-

vice valve and the liquid line service valve.

8. Before opening up any part of the low side of the

system, a slight positive pressure should be

indicated on the pressure gauge. If the pressure

is below 0 psig/ bar slowly open the liquid line

service valve slightly and then frontseat the

valve again. Repeat as necessary in order to

raise the pressure above zero.

9. Connect a refrigerant recovery device and a

clean refrigerant recovery cylinder to the suction

and discharge service valves and remove any

remaining refrigerant from the low side. DO

NOT bring the low side pressure below 0 psig/

bar.

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......