8–17

62-11640

10. After making necessary repairs, leak check and

evacuate the low side of the refrigeration sys-

tem. (Refer to

e. Pumping Down The Compressor

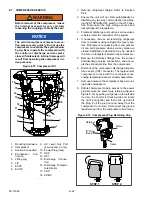

The compressor or any of the components attached to

it (high pressure switch, oil, etc.) may be serviced or

replaced by pumping the compressor down, and isolat-

ing the compressor from the rest of the system.

1. Install a manifold gauge set to allow reading of

suction and discharge pressure. See

2. If the compressor is operational, start the unit

and slowly frontseat the suction service valve.

shutdown the unit when the suction pressure

drops to 2 psig (0.2 bar). Ensure the unit will not

start automatically by disabling any two way

communication and placing the STOP/RUN-

OFF switch in the OFF position. Disconnect the

high voltage source and lockout/tagout the

receptacle. Frontseat the discharge service

valve to isolate compressor. There should be

very little refrigerant remaining in the compres-

sor at this point.

3. If the compressor is not operational, ensure the

unit will not start automatically by disabling any

two way communication and placing the STOP/

RUN-OFF switch in the OFF position. Discon-

nect the high voltage source and lockout/tagout

the receptacle. Frontseat both the discharge

and suction service valve to isolate the com-

pressor.

4. Connect a refrigerant recovery device and a

clean refrigerant recovery cylinder to the suction

and discharge service valves and remove any

remaining refrigerant from the compressor. DO

NOT bring the compressor pressure below 0

psig/bar.

5. After making necessary repairs, leak check and

evacuate the compressor. (Refer to

and

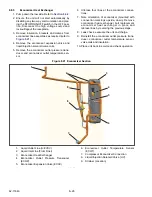

f. Adjusting The Charge Level

Adjustment of the charge level may be required when

there has been a leak or the system was not correctly

charged during a previous service.

1. Check charge level by performing the proce-

dures of the preceding step a.

2. If charge removal is required: connect a clean

evacuated refrigerant recovery cylinder to the

liquid line service valve. Open liquid valve on

cylinder. Midseat liquid line service valve and

monitor the liquid refrigerant flow into the cylin-

der. If the unit is operating, close the cylinder

valve and backseat the liquid line service valve

when the ball in the upper sight glass drops to

the bottom of the glass. If the unit is not operat-

ing, when approximately 5 lbs. (2.3 kg) have

been removed close the cylinder valve and

backseat the liquid line service valve. Proceed

to step 7.

3. If charge is to be added: place cylinder of refrig-

erant on a scale and connect a charging line

and gauge from cylinder to liquid line service

valve. Start unit in Continuous Operation with a

setpoint lower than refrigerated compartment

temperature. Wait until unit switches to high

speed operation. Run approximately ten min-

utes.

4. Note weight of cylinder and refrigerant.

5. Frontseat the liquid line service valve (turn

clockwise) and watch the pressure on the mani-

fold gauge. When the pressure falls below the

pressure in the refrigerant cylinder [or to 50 psig

(3.4 bar)], open the cylinder valve and monitor

the liquid refrigerant to flow into the unit.

6. When approximately 5 lbs. (2.3 kg) have been

added, close the cylinder valve, and backseat

the liquid line service valve.

7. Recheck for the correct refrigerant charge.

(Refer to preceding step a.) Repeat preceding

steps as required. When charge level adjust-

ment is complete, remove refrigerant service

equipment.

g. Adding a Complete Charge

1. Evacuate unit and leave in deep vacuum. (Refer

.)

2. Determine charge required for this unit (refer to

the model/serial number nameplate or

) and procure a refrigerant cylinder with suffi-

cient weight of refrigerant. Place cylinder on

scale and connect charging line from cylinder to

liquid line service valve.

3. Note weight of cylinder and refrigerant.

4. Open the liquid valve on cylinder. Midseat liquid

line service valve and allow liquid refrigerant to

flow into the unit until the correct weight of refrig-

erant has been added.

NOTE

It is possible that all the required liquid may

not be pulled into the receiver, as outlined in

step 4. In this case, add the additional refrig-

erant in accordance with the charge adjust-

ment procedures, refer to preceding step f.

5. When scale indicates the correct charge has

been added, close liquid valve on cylinder and

backseat the liquid line service valve. Remove

charging hose.

6. Start unit and run Pretrip to check operation.

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......