62-11640

8–20

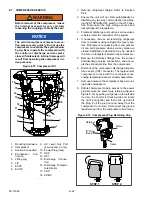

WARNING

!

Do not use a nitrogen cylinder without a

pressure regulator. Cylinder pressure is

approximately 2350 psig (159.9 bar). Do

not use oxygen in or near a refrigerant

system as an explosion may occur. (See

4. Connect a cylinder of dry nitrogen. Use the nitro-

gen to increase the compressor pressure 20 to

150 psig (1.4 to 10.2 bar) to detect the leak. The

larger the leak the less pressure is required. The

smaller the leak, the greater pressure required.

5. The recommended procedure for finding leaks

from a compressor connection is with an elec-

tronic leak detector. Checking joints with soap-

suds is satisfactory only for locating large leaks,

or pinpointing small leaks once a general area

has been located.

6. Once leak checking is complete, remove the

refrigerant/ nitrogen vapor from the compressor.

7. If no leaks are found the compressor is ready for

evacuation. (Skip to Step 10)

8. If any leaks are found they must be repaired

before proceeding.

9. Repeat steps 4 - 9 as necessary.

10. Disconnect the nitrogen cylinder. Evacuate the

compressor after all leaks are repaired. (Refer

to

.)

8.6.4

Evacuation and Dehydration

Moisture is detrimental to refrigerant systems. The

presence of moisture in a refrigeration system can

have many undesirable effects such as: copper plating,

acid sludge formation, “freeze-up” of the expansion

valve, and formation of acids, resulting in metal corro-

sion. Proper evacuation of the system will remove any

moisture from inside the system.

NOTE

1. Essential tools to properly evacuate any

system include a good vacuum pump (5 cfm/

8m

3

H volume displacement, Carrier Transi-

cold part number 07-00176-11) and a good

vacuum indicator such as a digital vacuum

gauge, Carrier Transicold part number 07-

00414-00.

2. The use of a compound gauge is not rec-

ommended for use in determining when the

evacuation process is completed because of

its inherent inaccuracy.

3. Standard service hoses are not recom-

mended for evacuation purposes. Evacua-

tion hoses are recommended for this

procedure.

a. Evacuation of the Complete System

1. Evacuate only after leak check. (Refer to

2. If possible keep the temperature of the major

components (condenser, evaporator, compres-

sor and receiver) above 60°F (15.6°C) to speed

evaporation of moisture. If the temperature is

lower than 60°F (15.6°C), ice might form before

moisture removal is complete. Heat lamps, heat

guns or alternate sources of heat may be used

to raise temperature.

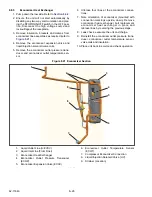

3. The recommended method to evacuate the sys-

tem is to connect three evacuation hoses with

vacuum pump and vacuum indicator (see

4. Ensure that the operator message panel dis-

plays “RECOVER/LEAK CHK/EVAC MODE”

during the evacuation and dehydration proce-

dures. (Refer to

.) If the control

system switches to Charge Mode during the

process, switch it back to the “RECOVER/LEAK

CHK/EVAC MODE”.

5. Backseat (turn counter-clockwise) the liquid line

service valve, suction service and discharge

service valves.

6. With the unit service valves closed (back

seated) and the vacuum pump and vacuum indi-

cator valves open, start the pump and draw a

deep vacuum. Shut off the pump and check to

see if the vacuum holds. This operation is to test

the evacuation setup for leaks. Repair if neces-

sary.

7. Midseat the refrigerant system service valves

and install the service valve caps. Ensure that

t h e o p e r a t o r m e s s a g e p a n e l d i s p l a y s

“RECOVER/LEAK CHK/ EVAC MODE”.

NOTE

The service valve caps help minimize leak-

age through valve stems during midseat

operation.

8. Start the vacuum pump. Evacuate unit until the

vacuum indicator indicates 2000 microns. Close

the vacuum pump valve and shut off the pump.

Wait a few minutes to ensure the vacuum holds.

9. Break the vacuum with dry nitrogen through the

discharge service valve. Raise system pressure

to approximately 2 psig (0.1 bar). Ensure that

the control system does not switch to the

Charge Mode. If this occurs, switch it back to the

“RECOVER/LEAK CHK/EVAC MODE” (Refer to

)

10. Purge nitrogen from system at the suction ser-

vice valve.

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......