62-11640

8–22

8.7

COMPRESSOR SERVICE

WARNING

!

Before removal of the compressor, relieve

the internal pressure by very carefully

loosening the couplings to break the seal.

NOTICE

The scroll compressor achieves low suc-

tion pressure very quickly. Do not use the

compressor to evacuate the system below

0 psig. Never operate the compressor with

the suction or discharge service valves

closed (frontseated). Internal damage will

result from operating the compressor in a

deep vacuum.

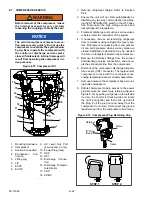

Figure 8.18 Compressor Kit

1. Remove refrigerant charge. Refer to

2. Ensure the unit will not start automatically by

disabling any two way communication and plac-

ing the STOP/RUN-OFF switch in the OFF posi-

tion. Disconnect the high voltage source and

lockout/tagout the receptacle.

3. Frontseat discharge and suction service valves

to help protect the remainder of the system.

4. If necessary, remove all remaining refrigerant

from compressor using refrigerant recovery sys-

tem. Refrigerant out gassing from compressor

oil can build pressure when service valves are

closed. Additional reclamation may be needed

to insure no refrigerant exists in the compressor.

5. Remove the Rotalock fittings from the suction

and discharge service connections, and uncou-

ple the economizer line from the compressor.

6. Disconnect the compressor discharge tempera-

ture sensor (CDT) connector. The replacement

compressor comes with the compressor dis-

charge temperature sensor already assembled.

7. Remove and save the compressor base

−

mount-

ing bolts and spacers.

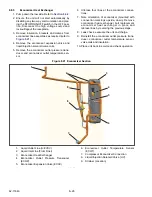

8. Rotate compressor to gain access to the power

plug. Remove the power plug retaining clip (see

) by pulling out gently on the left side

(to clear the shorter left locking tab and rotate

the right locking tab) and then slide up and off

the plug. Pull the plug out and away from the

compressor to remove. Disconnect the ground

lead/ terminal from the compressor circle fence.

Figure 8.19 Compressor Plug Retaining Clip

1. Mounting Hardware

2. Compressor

3. Suction Connection

4. Economizer Con-

nection

5. Lifting Lug

6. LIV

7. ECXV

8. ECOP

9. Oil Level Adj. Port

(service comp. only)

10. Power Plug (rear)

11. SSP

12. SPT

13. Discharge Connec-

tion

14. Discharge Tempera-

ture Sensor

15. CDP

16. CSMV

- - - - -

Retainer

Tether

Cable

“D” Ring

(Seal)

STEP 2

STEP 1

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......