62-11640

8–28

the gasket is installed in the body groove, and

torque the body screws 80 to 97 inch/lbs (9 to 11

Nm).

3. Leak check, evacuate & dehydrate, and charge

system as required. Refer to

,

&

8.8.7

Expansion Valves, EVXV & ECXV

The electronic expansion valves (EVXV = evaporator

expansion valve & ECXV = economizer expansion

valve see

) are automatic devices which

maintain constant superheat of the refrigerant gas

leaving the evaporator/economizer regardless of suc-

tion pressure. The valve functions are: (a) automatic

response of refrigerant flow to match the evaporator

load and (b) prevention of liquid refrigerant return to the

compressor. Unless a valve is defective, it seldom

requires any maintenance.

NOTE

As a preliminary valve check, ensure the coil

is snapped down fully, and the internal coil

retention tab is properly seated in one of the

valve body dimples. Also, check for a tem-

perature drop at the valve inlet strainer loca-

tion, indicating the strainer is restricted or

plugged.

a. Diagnostics

−

Microprocessor or Wiring

1. Locate the wires on the harness side labeled:

EXVA, EXVB, EXVC, EXVD and EXVE

or

ECVA, ECVB, ECVC, ECVD and ECVE

These will correlate to the connector pins

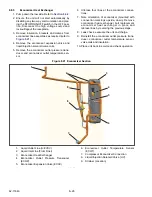

labeled A, B, C, D and E. Refer to

.

2. To test the EVXV, place the SROS in the Start/

Run position. DO NOT ALLOW THE UNIT TO

START. When the Message Center displays

“SMV CLOSING”, measure the AC voltage

between pins E & A and then between E & B, E

& C and E & D.

3. Test the ECXV, start the unit and bring the set-

point well below the refrigerated compartment

temperature to ensure the unit is operating in

Economized Mode. Measure the AC voltage

between pins E & A and then between E & B, E

& C and E & D. A voltage should be read by the

digital voltmeter for each pair of wires. If the

reading is present on all of the wire pairs there is

a good signal.

4. If the reading is not present on one or more of

the wire pairs, check the wiring between the

valve and the valve connector, or check the

Control System for proper model number Con-

figuration.

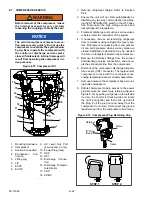

Figure 8.24 Evaporator Expansion Valve

b. Diagnostics - Stepper Motor

The valve stepper motor may be tested using a stepper

motor drive tester or ohmmeter.

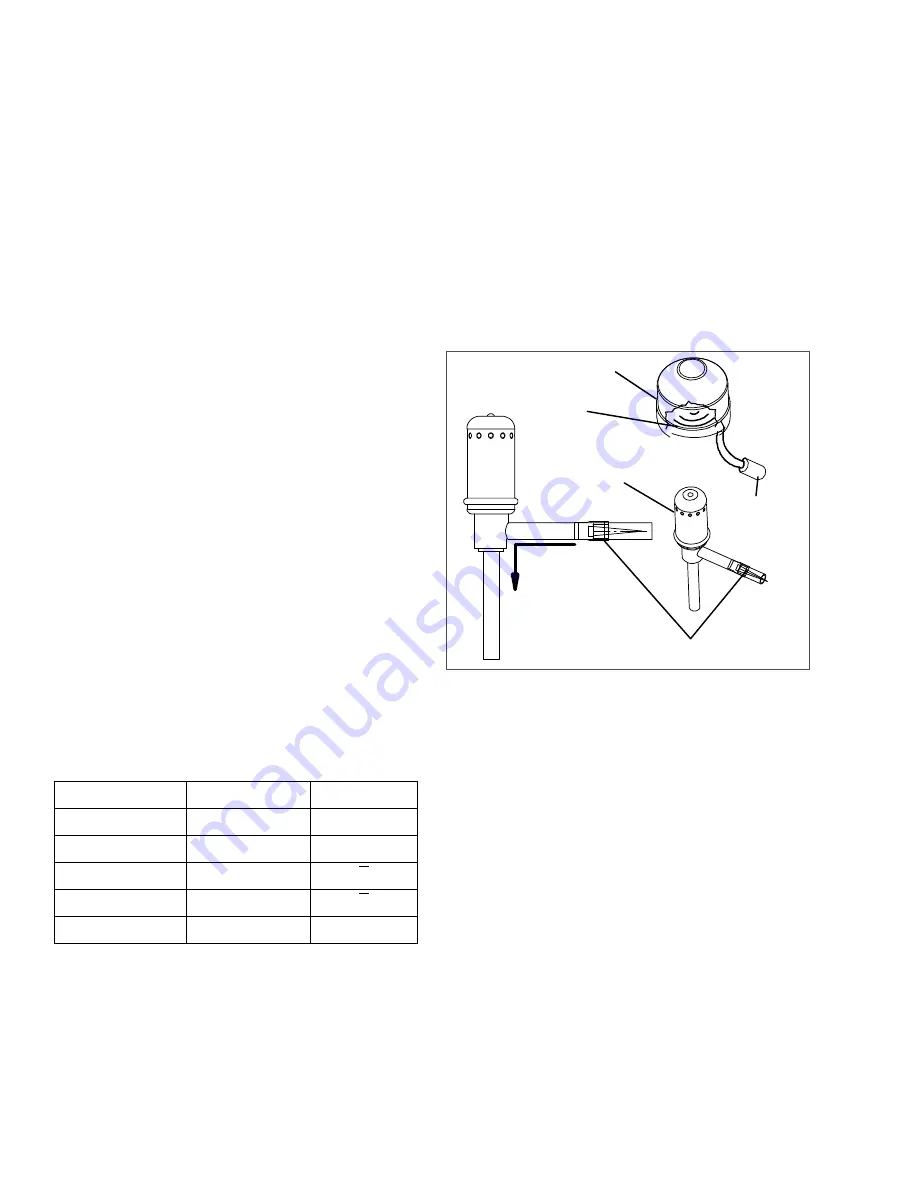

1. To test with a stepper motor drive tester (Carrier

Transicold part number 07

−

00375

−

00SV), con-

nect the 5 pin test cable to the valve connector

(see

), and the cable wires to the

tester in accordance with wire and terminal

color. (if a 5 pin tester cable is required, order

Carrier Transicold part number 07

−

00375

−

11.)

2. Set the step rate to 50 steps per second and

either open or close the valve. Each red LED

should light sequentially until all four are illumi-

nated. Any LED failing to illuminate indicates an

open on that leg and a need to replace the drive.

3. To test with an ohmmeter, check the winding

resistance between connector pin A & E, B & E,

C & E and then between D & E. In normal ambi-

ent, the resistance between the pins should be

46 ohms. If an infinite or zero reading is

observed, the piston and drive motor assembly

is to be replaced.

Table 8–2 Expansion Valve Connections

Connector Pin

Wire Color

Winding

A

ORANGE

A

B

RED

B

C

YELLOW

A

D

BLACK

B

E

GREY

COM (+12V)

FLOW

DIRECTION

Coil

Boot

Coil

Electronic

Expansion

Valve

Strainer

Five Pin

Connector

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......