2–1

62-11640

SECTION 2

UNIT DESCRIPTION

2.1

INTRODUCTION

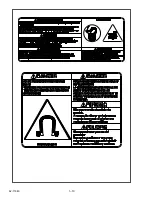

WARNING

!

APX control system equipped units may

start automatically at any time the

START/ RUN-OFF switch (SROS) is in the

START/ RUN position. Also, the unit may

be fitted with two way communication

equipment that will allow starting of the

unit from a remote location even though

the switch is in the OFF position.

WARNING

!

Be aware of HIGH VOLTAGE supplied at

the power plug or from the generator.

When performing service or maintenance

procedures: ensure any two way commu-

nication is disabled in accordance with

the manufacturer’s instruction, ensure

the START/ RUN-OFF switch is in OFF

position and, whenever practical, discon-

nect the high voltage source, lockout/

tagout the receptacle and disconnect the

negative battery connection.

This manual contains operating data, electrical data

and service instructions for the refrigeration unit listed

in

.

Additional support manuals are listed in

The unit model/serial number plate is located inside the

unit on the frame as shown in

2.2

GENERAL DESCRIPTION

The units described in this manual are hybrid/electric,

fully charged, pre-wired, refrigeration/heating “nose-

mount” units. The units are used on insulated refriger-

ated compartments to maintain cargo temperatures

within very close limits.

Electrical power is supplied to the unit from an external

source, at the power supply receptacle (PSR), or by

the AC generator which is driven by the engine. The

generator provides nominal 480V/3ph/60Hz power

when the engine is in high speed and nominal 350V/

3ph/45Hz power in low speed.

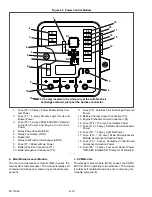

The control system includes a manual switch, control

modules, fuses, and associated wiring. High voltage

contactors, fuses and the contactor control boards are

located in the control box while contactors for the

optional standby electric power are located in the

standby box (see

). The unit may be

equipped with an optional remote light bar which

mounts separately on the front outside corner of the

refrigerated compartment.

Temperature control is provided by the Carrier Transi-

cold APX control system (Refer to

). Once

the system is set at the desired temperature, the unit

will operate automatically to maintain the desired tem-

perature within very close limits. When in Engine Oper-

ation, the control system automatically selects high and

low speed cooling or high and low speed heating as

necessary to maintain the desired temperature within

the refrigerated compartment.

Standard equipment includes an auto start-stop fea-

ture. This feature provides automatic cycling of the die-

sel engine, which in turn offers an energy efficient

alternative to continuous operation of the engine with

control of temperature by alternate cooling and heating

of the supply air (evaporator outlet air).

The unit may be equipped with the AutoFresh Air

Exchange which controls air quality and humidity for

fresh produce.

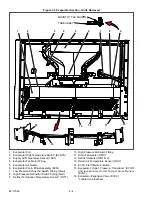

The unit is described as having three major sections:

), which includes the engine generator drive

package (

• the evaporator section (

)

• the control system (

)

Table 2–1 Model Chart

Model

R-404A

Compressor

Engine

Engine Speed

Vector 8500 NDK

LB

14

KG

6.35

Scroll

V2203L-DI-EF01e

High

1800

Low

1350

Table 2–2 Additional Support Manuals

Manual Number

Type of Manual

Manual Number

Type of Manual

62-11369 P

Parts Look Up System (PLUS)

62-11645

Easy To Run

62-11646

Operator’s Manual

62-11362

Engine Workshop Manual

Summary of Contents for Vector 8500

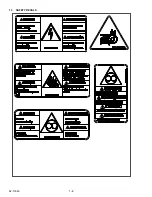

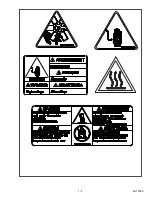

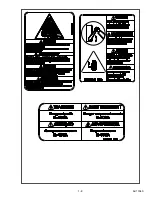

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......