62-11640

8–44

d. Generator Assembly Procedure

26. Verify the existence and condition of the two

original dowel pins in the bell housing. (See

−

06329

−

00

−

not included

in the kit. If replacement is required, the pins are

to be installed with the chamfer facing out.

WARNING

!

Never disassemble the generator rotor

from the stator due to the high force

required to do so and the high magnetic

field that will result. The field present

when the rotor is disassembled from the

stator may interfere with cardiac implants

such as pacemakers and defibrillator.

27. Note the position of the indexed guide rods in

relation to the indexed mounting holes in the

replacement rotor.

If the stator is not in correct alignment, back

out the flywheel locking tool sufficient to

allow the flywheel to rotate. Using a wrench

on the front pulley bolt, turn the engine suffi-

cient to allow aligning of the stator holes

with the dowel pins.

Slide the replacement generator on the

guide rods and move towards the engine,

aligning the stator on the dowel pins

Rotate the lifting tool lock out of the way as

the stator is brought onto the pins.

Using new bolts (DO NOT reuse original

bolts) install and snug three rotor bolts.

28. Using two flat washers on each, install the stator

bolts at the 5 o’clock (ensure ground strap is in

position on this bolt) and 8 o’clock positions.

Snug the bolts sufficient to hold the generator in

place on the engine. Remove the flywheel lifting

tool and then, using two flat washers install and

snug the stator mounting bolt at the 11 o’clock

position.

29. If required, re

−

lock the flywheel. Using new bolts

(DO NOT reuse original bolts), remove the

guide rods and install the remaining three rotor

bolts. Torque the six rotor bolts, using an alter-

nating pattern, to 45 ft/lbs (61 Nm) and then,

final torque the bolts to 90 to 110 ft/lbs (122 to

149 Nm).

30. Remove the mica shim shipping sleeve.

31. Install the fan (with the blades facing away from

the engine) and torque the fan bolt 12 to 14 ft/

lbs (16.3 to 19 Nm).

32. Remove the flywheel locking tool.

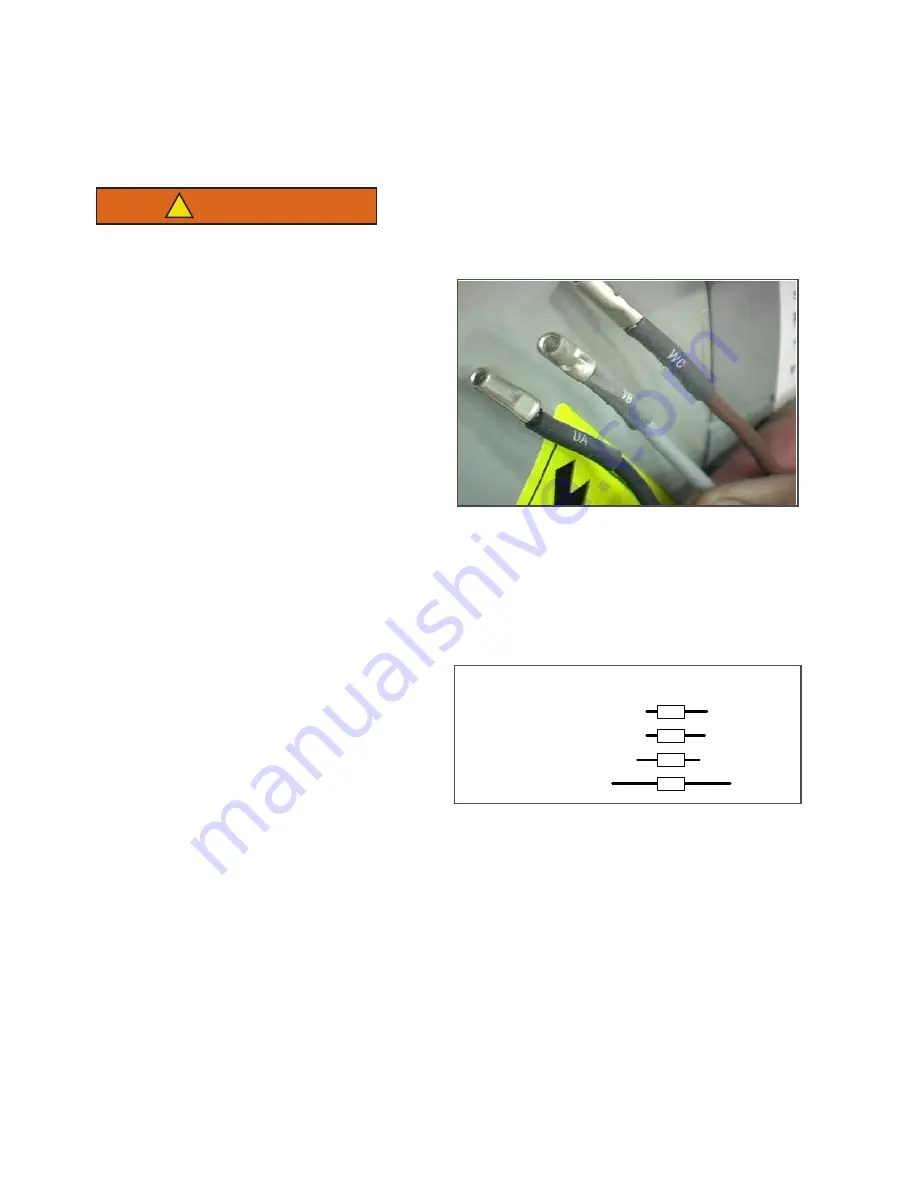

33. Prepare the replacement generator power wires

by installing four crimp splices (see

), one on each wire, and then route the

wires through the cover grommet.

34. Bring the cover in place, using two flat washers

on each, (only use one washer at 2 and 5

o’clock positions, see

) install the

remaining cover/ stator bolts and torque all

cover and stator blots 33 to 37 ft/lbs (44.7 to

50.2 Nm).

Figure 8.44 Generator Wires

Note: Green wire not shown

35. Slide the unidrive assembly back in place, and

then remove the engine support tool. Align,

install and torque all four mounting bolts 90 to

120 ft/lbs (122 to 163 Nm).

Figure 8.45 Generator/Harness Wire Connections

36. Use four pieces each ¼ inch and ½ inch heat

shrink (Carrier Part Number 66U1

−

3803

−

01 and

66U1

−

3803). Slide one piece of each size onto

the four generator wires. Install the harness

wires into the prepared crimps on the generator

wires and crimp in accordance with the color

coded crimps saved from dis

−

. Bring a ¼” heat shrink over the splice

and heat until a small amount of glue seeps out

from each end (sealing the connection), com-

plete the connection by doing the same with the

½” heat shrink. Repeat to cover and seal all four

splice connections.

37. Complete wire installation by gathering the four

wires and covering with tape (Carrier Part Num-

ber 02

−

00137

−

10). Refasten wiring in place to

the frame mount.

GENCON L1/GEN VB (black)

GENCON L2/GEN UA (white)

GENCON L3/GEN WC (red)

GREEN (W/Red Tape)

HARNESS

GENERATOR

GREY (VB)

BLACK (UA)

BROWN (WC)

GREEN

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......