2–17

62-11640

2.12 SAFETY DEVICES

The system is protected from high pressure conditions which may occur when exposed to very high temperatures

(such as a fire) by a fusible plug mounted in the receiver. Under very high temperature conditions (refer to

) the plug will melt, releasing the refrigerant pressure.

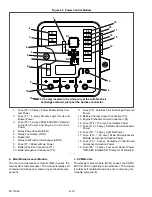

System components are protected from damage caused by unsafe operating conditions by automatic shut-down of

the unit when such conditions occur. This is accomplished by the safety devices listed in the following table and the

fuses shown in

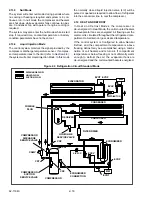

2.13 REFRIGERATION CIRCUIT DURING COOL-

ING

When cooling, the unit operates as a vapor compres-

sion refrigeration system. The main components of the

system are: the (1) scroll compressor, (2) air-cooled

condenser, (3) evaporator expansion valve, (4) direct

expansion evaporator and (5) economizer circuit.

The refrigeration system will operate in one of three

modes; Standard, Economized or Null. In addition, the

system may also operate in Liquid Injection mode. At

start and during periods of high refrigeration system

load, the system will operate in standard mode. This

allows the system to place the unit in operation at

reduced capacity and measure actual load. If the

microprocessor calculates additional capacity is

required and power is available (periods of high load or

during pull

−

down), the system will transition to econo-

mized mode.

2.13.1

Standard Mode

In standard mode, (see

), the compressor

raises the pressure and the temperature of the refriger-

ant and forces it into the condenser channels. The con-

denser fans circulate surrounding air over the outside

of the condenser. The channels have fins designed to

improve the transfer of heat from the refrigerant gas to

the air. This removal of heat causes the refrigerant to

condense. Liquid refrigerant leaves the condenser and

flows to the receiver.

The receiver stores the additional charge necessary for

low ambient operation. The receiver is equipped with a

fusible plug. The refrigerant leaves the receiver and

flows through the liquid line service valve to the sub-

cooler. The subcooler occupies a portion of the main

condensing coil surface and gives off further heat to the

passing air.

The refrigerant then flows through a filter-drier where

an absorbent keeps the refrigerant clean and dry.

The liquid then flows through the economizer (which is

not active in standard mode) and into the evaporator

expansion valve (EVXV). The EVXV reduces the pres-

sure of the liquid and meters the flow of liquid refriger-

ant to the evaporator to obtain maximum use of the

evaporator heat transfer surface.

The refrigerant pressure drop caused by the expansion

valve is accompanied by a drop in temperature so the

low pressure, low temperature liquid that flows into the

evaporator tubes is colder than the air that is circulated

over the evaporator tubes by the evaporator fan. The

evaporator tubes have aluminum fins to increase heat

transfer; therefore heat is removed from the air circu-

lated over the evaporator. This cold air is circulated

throughout the refrigerated compartment to maintain

the cargo at the desired temperature.

The transfer of heat from the air to the low temperature

liquid refrigerant causes the liquid to vaporize.

This low temperature, low pressure vapor passes the

evaporator outlet temperature and pressure sensors

(EVOT and EVOP) which aid in calculation of superheat.

The vapor then returns to the compressor through the

compressor suction modulation valve (CSMV). The

CSMV controls the flow of refrigerant entering the suc-

tion line, thereby matching the load to the compressor

capacity.

2.13.2

Economized Mode

In the economized mode the “main” refrigeration sys-

tem operates the same as in the Standard Mode

except the control system operates (opens) the econo-

mizer expansion valve (ECXV). With the economizer

expansion valve operating (see

ity of the unit is increased by subcooling the liquid

refrigerant entering the evaporator expansion valve.

Liquid refrigerant for use in the economizer circuit is

taken from the main liquid line as it leaves the filter

drier. This liquid refrigerant flows through the econo-

mizer expansion valve (ECXV) and the economizer

heat exchanger internal passages absorbing heat from

the liquid refrigerant flowing to the evaporator expan-

sion valve. Overall efficiency is increased because the

gas leaving the economizer enters the compressor at a

higher pressure, therefore requiring less energy to

compress it to the required condensing conditions.

There are two levels of economized mode, full econo-

mized mode and limited economized mode. Limited

economized mode is entered when the control system

requests higher capacity than standard mode but

engine power or system current limit will not allow full

economizer superheat control.

Unsafe Conditions

Safety Device

Device Setting

Excessive operating pressure

High Pressure Switch (HPS)

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......