4–3

62-11640

4.4.1

Engine Start-Up Sequence

On command to perform a Start-up the main micropro-

cessor will supply power from 3MM-10 to the fuel pump

(FP) and from 3MM

−

9 to ENCU-44. This signals the

ENCU that engine operation is required. The control

system will then enter the engine start sequence. During

the start sequence the engine is operated in low speed.

Following start, the refrigeration system will then operate

in the mode(s) required for temperature control.

The engine start sequence consists of periods of time

with the engine preheater (EPH

−

power from 3MM

−

14

through PCM

−

27 to EPHT) and starter (SM

−

power

from 3MM

−

12 to SS, closing SSC contacts) energized

and de-energized for up to three start attempts (see

), the pre-heat time will vary in duration based on

engine coolant temperature (refer to

If the A00129 - “CHECK ENGINE COOLANT SEN-

SOR” alarm is active, the ambient temperature sensor

will be used. If both the A00129 - “CHECK ENGINE

COOLANT SENSOR” alarm and the A00121 - “CHECK

AMBIENT SENSOR” alarms are active the control sys-

tem assumes a temperature of less than 32°F (0°C) for

the preheat timing.

During the last five seconds of preheat OR for 5 sec-

onds before a start attempt, if no preheat is required,

the buzzer (B) is energized; then the starter solenoid

contactor (SSC) will be energized for a maximum of ten

seconds while the engine condition is checked during

the cranking period. The engine is considered to be

running, and the start sequence will be stopped, when

engine speed is greater than 1000 rpm and the engine

oil pressure switch (ENOPS) is closed.

During the second and third attempts, the control sys-

tem will monitor additional inputs.

• When engine speed reading is less than 1000

rpm, ambient temperature is above 32°F (0°C)

and the ENOPS is closed - the A00130 - “CHECK

ENGINE RPM SENSOR” alarm will be activated

and the engine will be considered running.

• When engine speed reading is less that 1000

rpm, ambient temperature is below 32°F (0°C),

the ENOPS is closed and DC current is more

than 2 amps - the A00130 - “CHECK ENGINE

RPM SENSOR” alarm will be activated and the

engine will be considered running.

Once the engine is considered running, the control sys-

tem will keep the preheater energized for an additional

0 to 180 seconds of Post Heat, depending on engine

coolant temperature (refer to

During the start sequence the control system monitors

engine speed while cranking. If engine speed drops

below 50 rpm for three seconds the starter solenoid

contactor will be de-energized and the A00035 -

“CHECK STARTER CIRCUIT” alarm will be activated.

If the unit fails to start after three start attempts, the

A00031 - “FAILED TO START-AUTO“ alarm will be

activated.

If the unit is equipped with a fuel heater, the control

system will monitor ambient temperature. If ambient is

below 77°F (25°C) the fuel heater relay (FHR) will be

energized. Energizing FHR closes its normally open

contacts to supply power from fuse F14, through the

fuel heater temperature switch (FHTS) to the heater.

Refer to

for FHTS settings.

4.4.2

Transition To High Speed

After a successful start, the control system may call for

the engine to transition to high speed. When high speed

is required, the main microprocessor will provide a sig-

nal through the CAN system to the ENCU, calling for the

speed change. Three factors control this transition.

• First: transition may be delayed if a time value is

entered in the HIGH SPEED DELAY Configura-

tion. The delay may be set to 0 to 10 minutes.

The factory default setting is 1 minute.

• Second: if the engine is started when the coolant

temperature is 79°F (26°C) or below it will

remain in low speed until the coolant tempera-

ture reaches 79°F (26°C) or it has operated for a

minimum of 15 seconds. Once the coolant tem-

perature reaches 79°F (26°C) the engine may

transition to high speed.

• Third: transition will be based on the need for tem-

perature control. Generally, the engine will oper-

ate in high speed when the unit is in Pulldown or

Pull-Up Mode (full capacity required) and in low

speed when less than full capacity is required.

4.5

START-STOP OPERATION

Start-Stop is provided to reduce fuel or power con-

sumption. This feature allows full automatic control of

the unit by monitoring compartment temperature, bat-

tery condition and (when in Engine Operation) engine

coolant temperature.

The main function of Start-Stop Operation is to shut-

down the engine or compressor after certain conditions

are met (to provide an efficient temperature control

system) and to initiate a restart sequence after certain

conditions are met. The Start-Stop/Continuous key is

pressed to select between Continuous and Start-Stop

Operation. The mode of operation will be indicated in

the status bar.

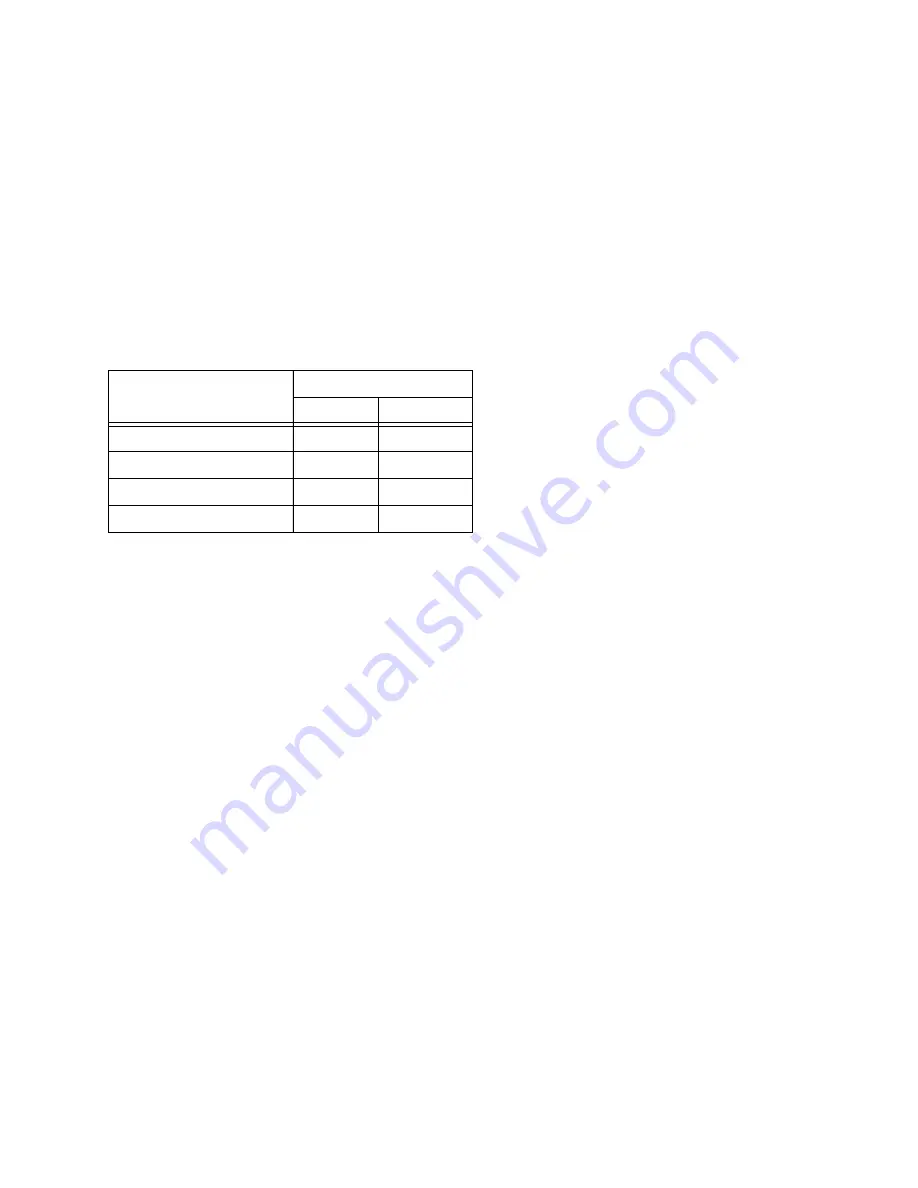

Table 4–1 Engine Preheat Time

Engine Coolant Tem-

perature

Heat Time in Seconds

Preheat

Post Heat

Less than 33°F (1.0°C)

30

180

33°F to 51°F (1.0 to 11°C)

20

120

51°F to 78°F (11 to 26°C)

10

60

Greater than 78°F (26°C)

0

0

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......