62-11640

5–12

5.4

TRU-TECH & TRU-VIEW

The TRU-Tech & TRU-View program allows the user to

access and download data using a computer, when the

unit is not running and without starting the eight-hour

DataLink data recorder timer. The application interface

will provide additional programming and configuring

capabilities that will not be available using the display

mounted keys. The DataLink data recorder may also

be configured using the TRU-Tech program.

For complete instructions on using TRU-Tech & TRU-

View, refer to the manual supplied with the TRU

−

Tech/

TRU

−

View software.

5.4.1

TRU-Tech

TRU-Tech enables the user to do the following:

• Monitor in real-time via the USB interface port

the current status of the control system inputs,

outputs, refrigeration, electrical, engine and tem-

perature sensors and alarms.

• Record sensor data to a file for diagnostic pur-

poses.

• Display, edit and send unit model number, unit

serial number and trailer ID to the main micro-

processor.

• Display, edit and send Functional Parameters

and Configuration settings to the System (includ-

ing the DataLink data recorder) or to a Data

Transfer USB memory device.

• Write hour meter values to a replacement main

microprocessors (during the first 25 hours).

• Initiate Pretrip and Defrost operations.

• Support Download, Configuration and Program

USB operations.

• Provide a security log on a system controlled by

a System Administrator.

5.4.2

TRU–View

TRU-View enables the user to do the following:

• Read download files from the System.

• Create various customized text reports that

include setpoint, sensors, and events.

• Create various customized graphical reports.

• Print numerical, graphical, and event reports.

• View and print refrigeration system historical set-

tings and changes.

• Filter download data by date range and desired

sensors and events.

• Search for a sensor or event of interest.

• Synchronize multiple graphical and numerical

windows to better understand historical operation.

• PC Setup enables the user to select how to dis-

play various parameters for use in the graph and

text window.

• Easily adjust x and y axis and color scheme to

accommodate various data.

• Export data to a user friendly format such as

PDF.

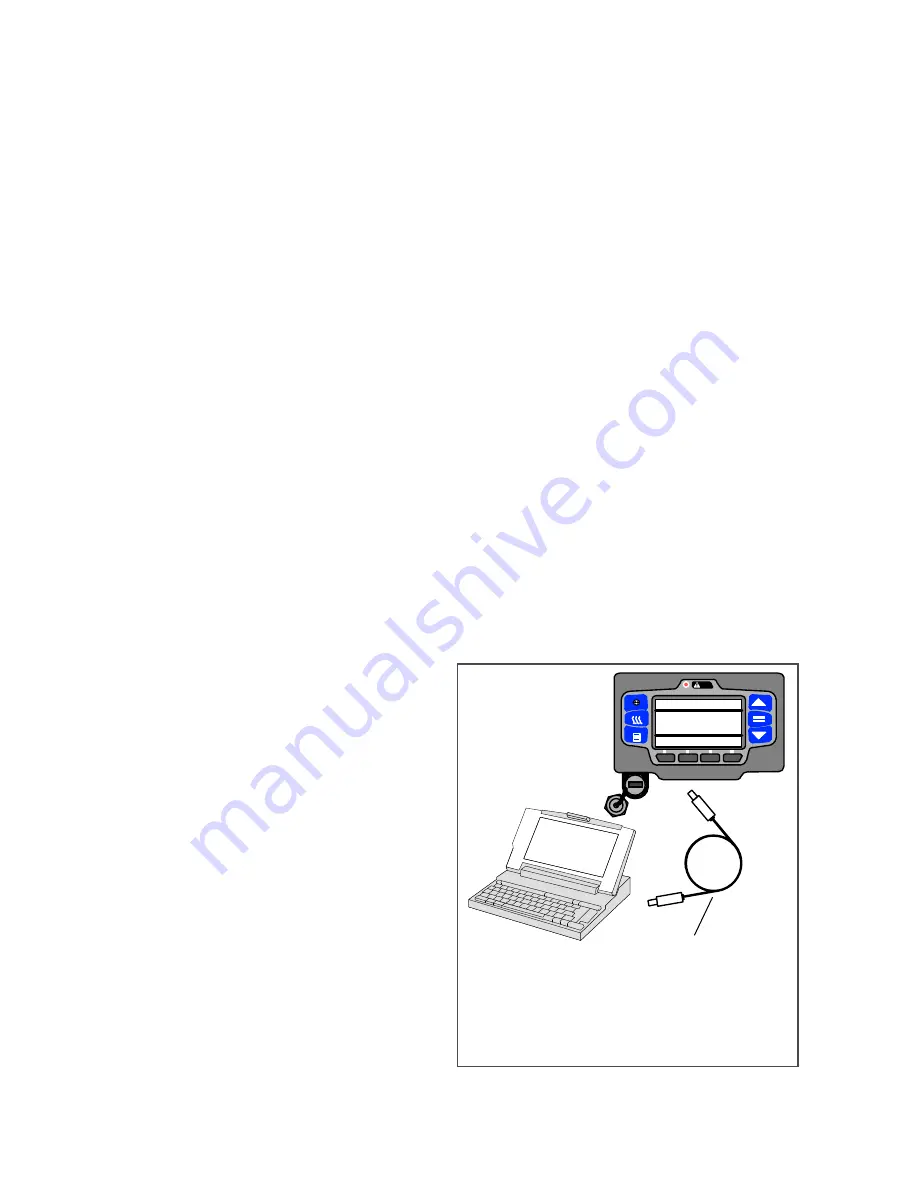

5.4.3

Connecting Computer and Control System

To connect the control system and computer:

1. Locate the USB interface port (

) and

remove the protective cover to gain access.

2. Plug a PC–USB service cable into the port and

a USB port on the computer (

).

NOTE

If SROS is off, the System will power up, and

display “PC MODE”.

3. Start the TRU-Tech & TRU-View program by

double clicking on the icon on your computer

desktop and entering the required password.

Verify that the correct COM port is selected in the

PC Setup. For complete instructions on using

TRU-Tech & TRU-View, refer to the manual sup-

plied with the TRU

−

tech/TRU

−

View software.

4. When work is complete, remove the interface

cable and install the protective cover back onto

the USB port. The control system will return to

normal operation.

Figure 5.10 TRU-Tech/TRU-View Connection

PC–USB Service Cable. Carrier Transicold

Part number:

22–04253–01 = 20 foot/6.1 meter long)

22–04253–00 = 6 foot/1.8 meter long)

NOTE: An “off the shelf” USB to USB cable

will not provide the required communication.

PRESS = TO LOAD, OTHER TO EXIT

SOFTWARE INSTALL MENU

CURRENT SOFTWARE VERSION:

##.##.01

SOFTWARE ON USB: ##.##.02

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......