8–7

62-11640

8.5.2

Priming the Fuel System

The mechanical fuel pump (See

) is

mounted on the engine next to the injection pump (See

). This pump has a manual plunger for prim-

ing the fuel system when the fuel tank has been run

dry.

To Prime the Fuel System:

1. If bleeding a spin–on system, considerable effort

may be saved by changing the filter and filling

the new element with clean diesel fuel before

priming the remainder of the system. Refer to

. If bleeding a suction side filter

system remove the vent cap from the filter bowl

and add fuel until level is about even with the

top of the filter element, reinstall cap. Do not

allow fuel level to fall below the visible level in

the bowl as the bleeding procedure is accom-

plished, add more fuel if required.

2. Turn the bleed valve (red) counter-clockwise

until fully opened.

3. Turn the top of the manual plunger counter-

clockwise to unlock it. S-L-O-W-L-Y (up/down

once per second) pump the manual plunger until

positive pressure (resistance) is felt. This may

take up to 200 strokes. This will indicate fuel

flow.

4. Continue to pump S-L-O-W-L-Y (up/down once

per second) approximately 100 more strokes to

fill the filter and bleed the air out of the lines.

5. Start engine. It may be necessary to continue to

pump until the engine starts.

NOTICE

Running the engine for an extended

period of time with the manual plunger up

can cause a priming pump failure

6. Depress and turn the top of the manual plunger

clockwise to lock in place.

7. When engine is running smoothly, turn bleed

valve clockwise until fully closed. If bleeding a

suction side filter system, loosen the vent on the

cover until fuel level lowers to the collar clamp

then hand tighten vent.

8.5.3

Mechanical Fuel Pump Screen

The fuel screen (See

or restricted with foreign particles or wax as a result of

using the wrong grade of fuel or untreated fuel in cold

weather. This will cause the engine to lose power. The

screen must be cleaned on a regular schedule such as

unit pre-trip or when the oil and fuel filters are changed.

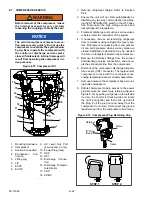

Figure 8.6 Mechanical Fuel Pump

1. Screen

2. Nut

3. Copper Rings

4. Banjo Fitting

- - - - -

To Check or Replace Screen:

1. Ensure the unit will not start automatically by

disabling any two way communication and plac-

ing the STOP/RUN-OFF switch in the OFF posi-

tion. Disconnect the high voltage source and

lockout/tagout the receptacle.

2. Turn nut (

loosen and remove it.

3. Remove banjo fitting and let it hang loose. Dis-

card copper rings and replace with new ones.

4. Turn screen counter-clockwise and remove.

Check and clean or replace as required.

5. To install reverse above steps.

6. Start unit and check for leaks.

Figure 8.7 Electric Fuel Pump

Bowl

Screen

Gasket

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......