8–27

62-11640

8.8.6

Compressor Suction Modulation Valve

(CSMV)

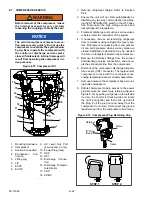

The purpose of the CSMV (see

) is to main-

tain the compressor within its operating envelope, max-

imize unit capacity and fuel economy, maintain

temperature control and engine power.

Figure 8.22 Suction Modulation Valve

If it is suspected that the CSMV is malfunctioning, the

most efficient method of diagnosing the valve is to run

a Pretrip (refer to

). The Pretrip steps will

check the remainder of the system and the CSMV spe-

cific test will check the valve. During the CSMV specific

test the valve will be brought to a preset position, the

unit started and then the valve will be opened while the

control system monitors suction pressure. If there is a

problem with the valve internal motor/piston assembly

or control system wiring to the valve the test will fail.

a. Diagnostics - Control System or Wiring

1. Disconnect the CSVM connector.

2. Place the STOP/RUN-OFF switch in the

START/ RUN position, DO NOT ALLOW THE

UNIT TO START. When the MessageCenter

displays “SMV CLOSING”, measure the AC volt-

age on the harness side of the connector

between pins A & B and then between C & D. A

voltage (10 to 16 VAC) should be read by the

digital voltmeter for each pair of wires. If the

reading is present on all of the wire pairs there is

a good signal coming from the control system.

3. If the reading is not present on one or more of

the wire pairs, check the wiring between the

control system and the CSMV connector, or

check the control system for proper model num-

ber Configuration.

b. Diagnostics - Stepper Motor (SMV)

The valve stepper motor may be tested using a stepper

motor drive tester or ohmmeter.

1. To test with a stepper motor drive tester (Carrier

Transicold part number 07-00375-00SV), connect

the 4 pin test cable supplied with the tester to the

valve connector, and the cable wires to the tester

in accordance with wire and terminal color.

2. Set the step rate to 150 steps per second and

either open or close the valve. Each red LED

should light sequentially until all four are illumi-

nated. Any LED failing to illuminate indicates an

open on that leg, and a need to replace the pis-

ton and drive motor assembly.

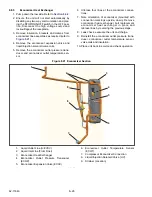

3. To test with an ohmmeter, check the winding

resistance between connector pin A & B and

then between C & D, see

ambient, the resistance between the pins should

be 65 to 84 ohms. Also check each terminal to

the coil casing (ground). If an out of tolerance or

zero reading is observed, the piston and drive

motor assembly is to be replaced.

Figure 8.23 CSMV Coil

c. Diagnostics - Valve

NOTE

If the valve failed pretest and passed the

preceding diagnostic testing, this is an indi-

cation that the valve mechanism is damaged

and the internal motor/piston assembly is to

be replaced.

1. To test the valve internal mechanism, install a

manifold gauge set on the suction service valve

and a stepper motor drive tester.

2. Start the unit, set the step rate to 150 steps per

second and close the valve while watching the

suction pressure. Within one minute the suction

pressure should begin to fall. Place the STOP/

RUN-OFF switch in the OFF position before the

reading enters a vacuum.

3. If the suction pressure does not change, this is

an indication the valve is stuck and the internal

motor/piston assembly is to be replaced.

d. Replace the Internal Motor/Piston Assembly

1. Pump down the low side. Refer to

.

2. Remove internal motor/piston assembly and

replace with a new assembly and gaskets. The

motor/piston assembly should be set to 100%

open when received from the warehouse. This

is to ensure the valve seal is not damaged when

it is installed. Ensure the valve is fully open by

using the stepper motor tester to manually open

the valve to 100% before it is installed. Ensure

4 Pin Connector

Drive & Motor

Assembly

Screws

Body

1

2

A (BLACK)

(WHITE) B

(RED) C

D (GREEN)

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......