8–31

62-11640

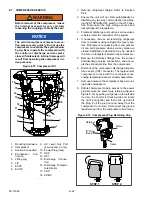

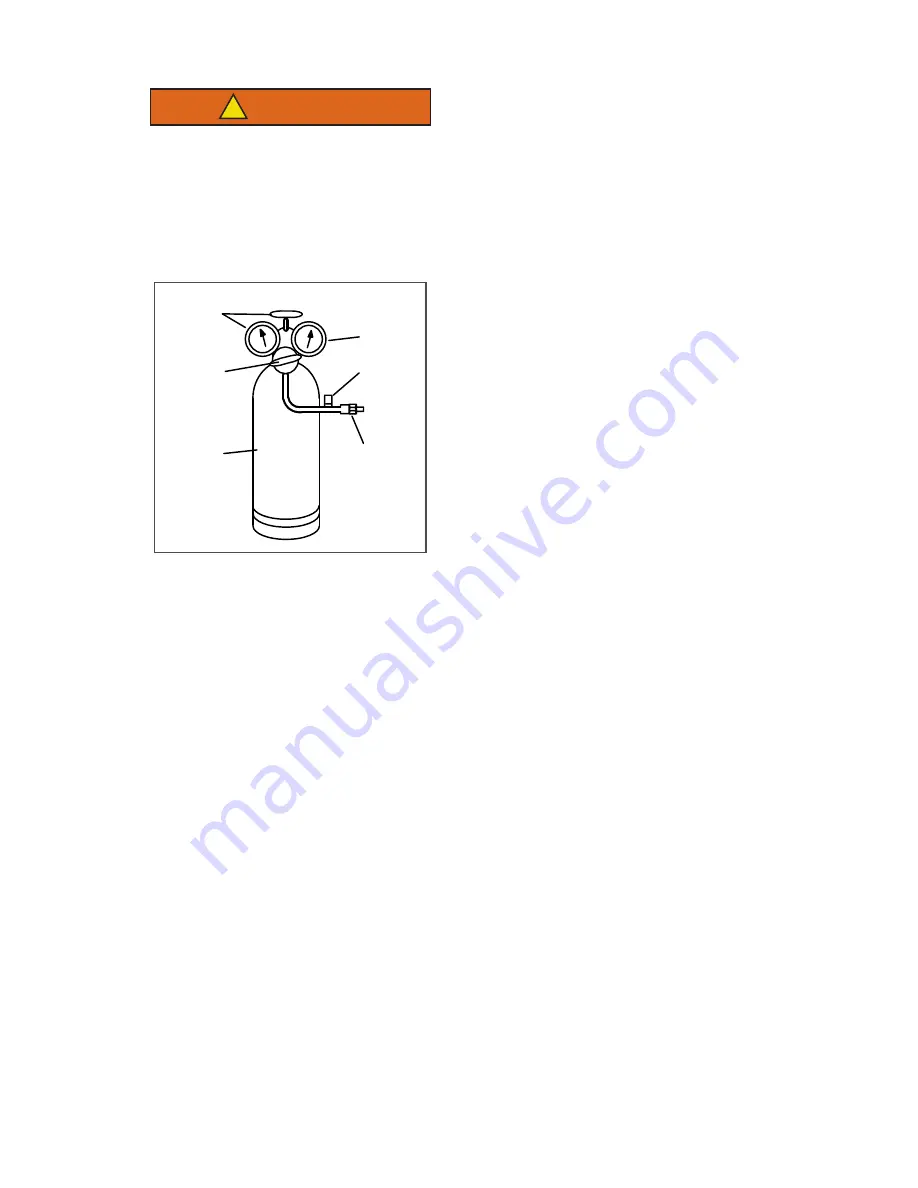

b. Checking High Pressure Switch

WARNING

!

Do not use a nitrogen cylinder without a

pressure regulator. Cylinder pressure is

approximately 2350 PSIG (160 bar). Do

not use oxygen in or near a refrigerant

system as an explosion may occur. (See

Figure 8.27 Testing High Pressure Switch

1. Cylinder Valve and Gauge

2. Pressure Regulator

3. Nitrogen Cylinder

4. Pressure Gauge 0 to 500 PSIG (0 to

27.2 bar)

5. Bleed-Off Valve

6. Switch

- - - - -

1. Remove switch as outlined in preceding section.

2. Connect ohmmeter or continuity light across

switch terminals. Ohmmeter will indicate resis-

tance and continuity light will be illuminated if

switch closed after relieving pressure.

3. Connect switch to a cylinder of dry nitrogen.

4. Set nitrogen pressure regulator higher than

open setting for switch being tested. For pres-

sure switch settings refer to

5. Close valve on cylinder and open bleed-off

valve.

6. Open cylinder valve. Slowly close bleed-off

valve and increase pressure until the switch

opens. If light is used, light will go out and if an

ohmmeter is used, the meter will indicate open.

Close cylinder valve. Slowly open bleed-off

valve (to decrease pressure) until switch closes

(light will illuminate or ohmmeter will indicate

open).

8.8.10

Pressure Transducers

The compressor discharge pressure transducer (CDP)

has a range of 0 to 500 PSIG (0 to 34.0 bar) while the

compressor suction pressure transducer (CSP), evapo-

rator outlet pressure transducer (EVOP), and econo-

mizer pressure transducer (ECOP) have a range of -

14.7 to 100 PSIG (-1 to 6.8 bar). When comparing the

transducer reading in Unit Data to the reading on a

manifold gauge, keep in mind the following:

1. The compressor discharge pressure reading in

Unit Data will never read less than 0 bar/psig,

even if it is exposed to a vacuum (such as when

evacuating the system).

2. If the compressor discharge pressure trans-

ducer has lost power or the signal is not return-

ing to the module the reading in Unit Data will

default to 305 to 315 psig (20.75 to 21.43 bar).

Comparisons in this pressure range are not con-

clusive.

3. The compressor suction pressure and evapora-

tor pressure transducers will never read higher

than 100 psig, even if the actual pressure is

higher.

4. If the compressor suction pressure or evapora-

tor pressure transducer has lost power or the

signal is not returning to the module the reading

in Unit Data will default to 55 to 60 psig (3.74 to

4.08 bar). Comparisons in this pressure range

are not conclusive.

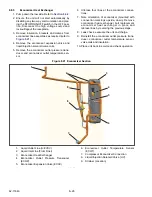

Test Transducer Wiring:

1. Verify that the wiring to the transducer is correct.

NOTE

The CDP connector is identified with a red

tape band while the CSP connector is identi-

fied with a blue band.

2. If required, power the transducer circuit by plac-

ing the unit in PC Mode, refer to

Check Voltage to transducer connector. Voltage

reading between connector position 2 (positive)

and position 1 (negative) should be 5.0 VDC.

3. To check the signal wiring, check continuity

between the transducer connector position 3

and the following connector:

CDP = 2MM

−

10, CSP = 2MM

−

9, EVOP =

2MM

−

17

4. If voltage and signal wire are good, replace the

transducer.

Replace a Transducer:

The transducer may be removed by disconnecting the

connector and quickly backing it off the Schrader valve

fitting. Torque replacement transducer 13 to 15 ft/lb

(17.6 to 20.3 Nm).

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......