62-11640

8–34

8.9.3

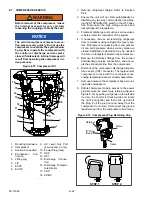

Stepper Valve Module (SVM)

1. Ensure unit will not start automatically by dis-

abling any two way communication, placing the

STOP/ RUN-OFF switch in the OFF position

and removing the negative battery cable. Dis-

connect the high voltage source and lockout/

tagout the receptacle.

2. Unlock the tabs on and remove the two 35 pin

connectors and 8 pin connector from the front of

the module.

3. Replace module. Tighten mounting hardware to

96 inch/lbs (10.8 Nm).

4. Reinstall connectors ensuring tabs are fully

locked in place.

5. Start unit and run Pretrip to check operation.

8.9.4

Display Module (DM)

1. Ensure unit will not start automatically by dis-

abling any two way communication, placing the

STOP/ RUN-OFF switch in the OFF position

and removing the negative battery cable. Dis-

connect the high voltage source and lockout/

tagout the receptacle.

2. Unlock the tabs on, and then remove the 14 pin

connector from the back of the module.

3. Remove hardware at rear of module. Replace

module. Tighten mounting hardware to 84 to

120 inch/lbs (9.5 to 13.6 Nm).

4. Reinstall connector ensuring tabs are fully

locked in place.

5. Make sure the latest software has been loaded

to ensure all modules are compatible, refer to

.

NOTICE

When a module is replaced, software

should be upgraded before switching the

unit on. This will ensure software com-

patibility of all modules.

6. Start unit and run Pretrip to check operation.

8.9.5

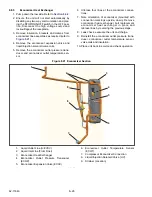

Contactor Control Board (CCB)

The two Contactor Control Boards, CCB1 & CCB2 are

located behind the control box. To service a CCB do

the following:

1. Ensure the unit will not start automatically by

disabling any two way communication, placing

the STOP/RUN-OFF switch in the OFF position

and removing the negative battery cable. Dis-

connect the high voltage source and lockout/

tagout the receptacle.

NOTICE

Electronic modules MUST be handled

with care to prevent accidental damage

or degradation from electrical static dis-

charge (ESD), contamination or abuse.

Before touching a module, touch your

body and/or conductive tool being used

to the frame to discharge ESD safely. All

electronics should be handled carefully

and only held by edges of any exposed

board. Care should be taken when insert-

ing/extracting connectors and compo-

nents to avoid exerting excessive stress

on the board which could fracture small

components nearby resulting in future

failure of circuit.

2. Attach a grounded wrist strap (CTD P/N

07

−

00304

−

00) and ground it to a good unit

frame ground.

3. Remove the four control box cover bolts, then

the remove the cover ground cable. Set the

cover off to the side.

4. Remove the 2 nuts that secure the PE plate to

the box and remove the 2 nuts that secure the

current transformer to the control box.

5. Move the PE plate and the current transformer

off the studs towards the center of the box.

6. Remove the two nuts located at the bottom of

the sub panel.

7. Disconnect the connectors from CCB1 and

CCB2 and remove two nuts.

8. Remove upper mounting bolts.

NOTE

At this point the sub panel may start to swing

out of the box. It is best to hold it in while

removing the last bolt.

Change 09/14

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......