62-11640

2–6

2.3

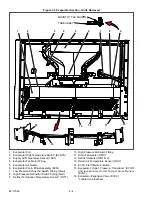

CONDENSING SECTION

The condensing section (see

)

consists of an engine-generator drive package, com-

pressor, condenser fans, condenser, radiator, econo-

mizer, refrigerant controls, defrost air switch, piping,

wiring, and associated components. The condensing

section may also be equipped with an AutoFresh Air

Exchange.

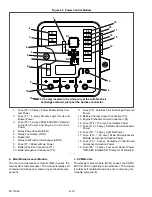

The engine-generator drive package (see

includes the engine, generator, air cleaner, muffler,

coolant system, fuel system, engine oil filter system

and engine sensors.

2.3.1

Engine

The engine is a four cylinder diesel which gives excel-

lent fuel economy. The engine cooling system consists

of the radiator (which is mounted with the condenser

coil) and coolant overflow bottle. The engine is

equipped with:

• an engine preheater (EPH), which provides easy

starting characteristics.

• spin-on engine oil filter and a spin

−

on or suction

side fuel filter for easier filter changes. The fuel

filter may also be equipped with a thermostati-

cally controlled fuel heater.

• an electronic battery charger which converts

generator or standby alternating current to direct

current for battery charging.

2.3.2

Engine Air System

The air cleaner prolongs the life and performance of

the engine by preventing dirt and grit from getting into

the engine and causing excessive wear on all operat-

ing parts. It is the responsibility of the operator to give

the air cleaner equipment regular and constant atten-

tion in accordance with the instructions. An air cleaner

service indicator is connected at the outlet. Its function

is to indicate when the air cleaner filter element

requires replacement. (Refer to

The system may be fitted with an intake air tempera-

ture sensor (IAT) and a manifold absolute pressure

transducer (MAP). These sensors are installed when

Carrier Transicold factory monitoring of the air system

is required.

2.3.3

Engine Controls

a. Fuel/Speed Actuator (FSA)

The FSA combines the fuel shutoff solenoid and speed

control solenoid into one component. Fuel supply to the

injectors and engine speed is controlled by varying rod

position in accordance with the signal from the control

system. In order to ease the load on the system, speed

transition (high to low and low to high) is ramped up or

down over a 10 second period. The FSA is located on

the front of the gear case cover.

b. Engine Speed Sensor (ENSSN)

The ENSSN provides the control system with informa-

tion on the speed at which the engine is running. The

ENSSN is located in the gear case cover above the

engine oil filter.

c. Rack Position Sensor (RPS)

The RPS provides the control system with engine fuel

rack (throttle) position information to be used to control

the engine and refrigeration system. The sensor is

located on the injection pump.

d. Engine Oil Pressure Switch (ENOPS)

The ENOPS is normally open and closes on pressure

rise to signal to the control system the engine has suffi-

cient oil pressure for operation. There is a 15 second

delay after the engine starts to allow the oil pressure to

build up before the control system looks at the input

from this switch. The switch is located in the oil filter

mounting assembly.

e. Engine Coolant Temperature Sensor (ENCT)

The ENCT is a thermistor type sensor that provides the

control system with engine coolant temperature infor-

mation to be displayed, recorded in the DataLink data

recorder and used to control the engine and refrigera-

tion system. The sensor is located on the starter side of

the engine near the #4 injector.

2.3.4

Generator (GEN)

The generator is directly bolted to the engine and sup-

plies nominal 460V/3Ø/60Hz power when the engine is

in high speed and nominal 345V/3Ø/45Hz power in low

speed.

The generator may be fitted with a generator tempera-

ture sensor (GNT). This sensor is installed when Car-

rier Transicold factory monitoring of the system is

required.

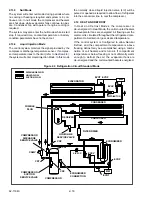

2.3.5

Compressor

The unit is fitted with a scroll compressor equipped with

suction and discharge service valves and an econo-

mizer connection. The compressor draws refrigerant

gas from the evaporator and delivers it to the con-

denser at an increased temperature and pressure. The

pressure is such that refrigerant heat can be absorbed

by the surrounding air at ambient temperatures.

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......