ANSI/NFPA 211: CHIMNEYS, FIREPLACES, VENTS, AND

SOLID FUEL BURNING APPLIANCES

ANSI/NFPA 90B: WARM AIR HEATING AND AIR CONDI-

TIONING SYSTEMS

ANSI/NFPA 70: NATIONAL ELECTRICAL CODE

CSA B139: INSTALLATION CODE FOR OIL BURNING

EQUIPMENT

CAS C22.1: CANADIAN ELECTRICAL CODE

Only the latest issues of these codes should be used, and are

available from either The National Fire Protection Agency, Bat-

terymarch Park, Quincy, MA 02269 or The Canadian Standards

Association, 178 Rexdale Blvd., Rexdale, Ontario M9W 1R3.

Recognize safety information. This is the safety-alert symbol

.

When you see this symbol on the furnace and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION

and NOTE. These words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies a hazard

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which would result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

INTRODUCTION

The model 58CLA Furnaces are available in 2 sizes. Each size unit

can be fired at 3 different rates by a simple nozzle change. Unit

105-12 covers input ranges from 91,000 to 105,000 Btuh, unit

120-20 covers input ranges from 119,000 to 154,000 Btuh.

This furnace is a Low-Boy unit. It may be operated only in the

upflow configuration.

The furnace is shipped as a packaged unit, complete with burner

and controls. It requires a line voltage (115 vac) connection to

control box, a thermostat hook-up as shown on wiring diagram, oil

line connection(s), adequate duct work, and connection to a

properly sized vent.

The air handling capacity of this furnace is designed for cooling

airflow. Refer to Table 12 for expected airflows at various external

duct static pressures.

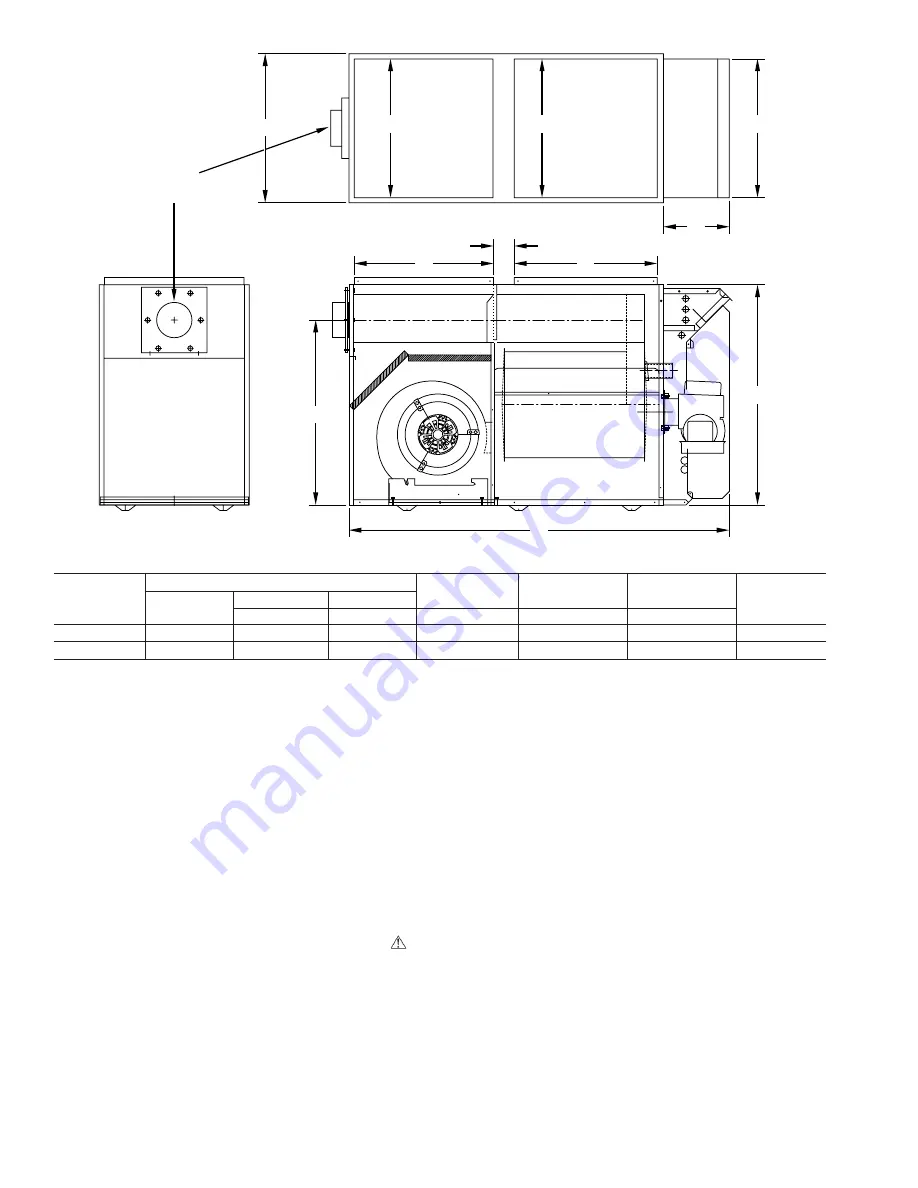

Fig. 2-Dimensional Drawing

Dimension (IN.)

UNIT

SIZE

UNIT DIMENSIONS

FLUE

HEIGHT

RETURN

OPENING

SUPPLY

OPENING

VENT

CONN

Width

Depth

Height

A

B

C

D

E

105-12

21-1/4

53-3/4

31-1/2

26-1/2

20

20

5

120-20

21-1/4

60-5/32

34-3/4

28-11/32

22

24

6

A98009

A

D

10"

E

3"

B

C

21

1

⁄

4

″

20"

20"

20"

VENT

CONN

2